What Surfaces Does Rub N Buff Work On?

Rub n Buff is a unique wax-based metallic finish used to add distressed, vintage-looking effects to a variety of surfaces like metal, wood, glass, and more. According to the Rub n Buff website, the product was invented in the 1970s by Bonnie and Marc Schiller as an easy way to antique and distress furnishing hardware [1]. It quickly became popular among crafters and DIYers for giving an aged, patinated look to projects with just the swipe of a cloth.

Some key facts about Rub n Buff:

- Comes in a paste-like formula packed in a tube for easy application

- Contains real metallic particles like copper, silver, and gold suspended in a wax base

- Goes on smoothly and dries to a hard finish within minutes

- Available in a wide range of metallic tones from silver to copper to black

- No special tools or training needed – simply apply with a soft cloth

Today, Rub n Buff is popular for distressed DIY projects, upcycling furniture, adding patinas to jewelry, and even theatrical makeup. Its versatility and ease of use make it a go-to product for crafters and artists looking to add an aged, vintage touch to their work.

Types of Rub n Buff

Rub n Buff comes in two main types: wax-based and oil-based. The type you choose depends on the specific look and finish you want to achieve.

Wax-Based Rub n Buff

Wax-based Rub n Buff contains wax combined with powdered metal pigments. It produces a smooth metallic finish with a subtle sheen. Wax-based Rub n Buff works best on materials like wood, metal, glass, and ceramics. It adheres well to these non-porous surfaces and provides even coverage. The smooth waxy finish resists fingerprints and smudges. It can be built up in layers for a bold metallic look. Wax-based Rub n Buff dries fast and resists rubbing off over time. It’s easy to apply and control.1

Oil-Based Rub n Buff

Oil-based Rub n Buff uses oils mixed with powdered metal pigments. It leaves behind a metallic finish with a brighter, shinier look compared to wax-based. Oil-based works well on porous surfaces like paper, plaster, concrete, and clay. The oil penetrates these materials, binding the pigments together. Multiple coats can be applied for a bolder finish. Oil-based Rub n Buff takes longer to dry and requires sealing for protection. The shinier finish also shows fingerprints and smudges more easily. Oil-based offers a beautiful, vivid metallic look perfect for arts, crafts, and decorative finishes.2

Best Surfaces for Rub n Buff

Rub n Buff can be used on a variety of surfaces, but works especially well on metals, wood, glass, and ceramics/pottery.

Metals

Rub n Buff is commonly used on metal surfaces like brass, copper, pewter, silver, and gold. It adheres well to smooth metals and brings out a glossy metallic finish. According to this source, metal surfaces just need to be clean before applying Rub n Buff.

Wood

Rub n Buff can also be used on wooden surfaces. It works on both stained and painted wood. For best results, the wood surface should be sanded smooth before applying Rub n Buff. According to this source, wipe wooden surfaces with mineral spirits if they are dirty or grimy.

Glass

Smooth glass surfaces like vases, bottles, and drinking glasses are great candidates for Rub n Buff. Make sure the glass is clean and dry first. Rub n Buff will give glass a striking metallic look.

Ceramics/Pottery

Unglazed ceramics and pottery can be transformed with Rub n Buff. The metallic finishes work nicely on ceramic surfaces like flower pots, mugs, figurines, and decorative bowls. As with other surfaces, clean the ceramic well before starting.

Preparing Surfaces for Rub n Buff

Proper surface preparation is key for getting the best results with Rub n Buff. The surface needs to be clean and lightly sanded before applying Rub n Buff.

First, clean the surface thoroughly with soap and water to remove any dirt, grease or existing finishes. For metal surfaces, you can use a degreasing agent like mineral spirits for a deep clean. For wood, use a tack cloth to pick up any remaining dust or debris after sanding (Thrifty Decor Chick, 2021).

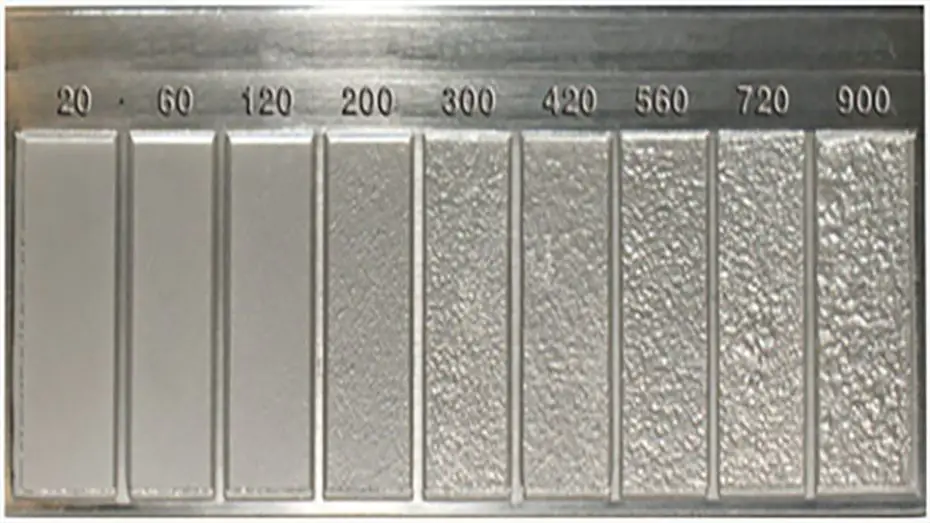

Next, lightly sand the surface to rough it up and help the Rub n Buff adhere better. Use fine grit sandpaper (220 or higher) so you don’t take off too much finish. For wood, sand with the grain. For metal, rub in small circles to evenly scratch the surface. Remove any sanding residue with a dry cloth or tack cloth (Driven by Decor, 2022).

Priming or basecoating the surface first can also help prepare for Rub n Buff. For wood, an oil-based primer seals the grain so the wax doesn’t absorb unevenly. For metal, a spray primer like Rust-Oleum fills in scratches and provides tooth. Let primer dry completely before applying Rub n Buff. Using a compatible basecoat in a similar color to your Rub n Buff shade can help build up color too.

With proper cleaning, sanding and potentially priming beforehand, you’ll get professional results from Rub n Buff on any surface including wood, metal, glass and more.

Applying Rub n Buff

Rub n Buff comes in both wax and oil-based formulas. The application technique differs slightly between the two. For wax-based Rub n Buff, you’ll want to use a soft cloth or foam applicator. Dip the applicator lightly into the wax and wipe off any excess on the edge of the jar before applying in thin, even coats. Allow each coat to dry completely before adding another layer. Multiple thin layers will give better results than applying one thick coat.

For oil-based Rub n Buff, you can use a soft cloth, foam applicator, or brush. Apply in smooth, thin coats, removing any excess oil and buffing as you go. Oil-based Rub n Buff dries quite quickly, so you’ll want to work in small sections. Allow the finish to dry completely between coats. Two to three thin coats typically provides good coverage.

When applying Rub n Buff, avoid putting too much on at once or leaving globs of product on the surface. Work in a well-ventilated area and frequently change applicators to prevent transferring too much product. Gently buff the finish as you work to remove excess and create an even, smooth coat. Be patient and allow proper drying time between layers for best results.

Sealing the Finish

Sealing the Rub n Buff finish is an optional step, but can help protect and preserve the finish. Using a sealant like varnish or lacquer helps prevent the finish from tarnishing, wearing off, or reacting to moisture over time. Here are some tips on sealing Rub n Buff:

Most experts recommend using 1-3 thin coats of an acrylic lacquer or polyurethane varnish to seal the Rub n Buff finish. Lacquer sprays tend to dry harder and more durable than polyurethanes. Be sure to use a water-based, non-yellowing formula, otherwise it may tint the Rub n Buff finish. Apply light even coats, avoiding runs or drips which can affect the finish. Let each coat dry fully before applying the next.

Two sources recommend specific sealants that work well with Rub n Buff:

According to this forum post, Krylon Clear Acrylic spray provides “an ideal protective clear” when used over Rub n Buff.

This article from Twelve on Main suggests using a water-based polyurethane like Minwax Polycrylic to seal Rub n Buff finishes.

Be sure to follow the manufacturer’s instructions for proper application and drying time between coats. Allow the final sealed finish to cure fully, up to 7 days, before handling the piece to avoid damaging the sealant.

Advanced Rub n Buff Techniques

Once you’ve mastered the basics of applying Rub n Buff, you can try some more advanced techniques to create unique metallic finishes.

Layering Colors

You can layer different colors of Rub n Buff to create a multi-dimensional, antiqued effect. Start with a base coat of a darker metallic like European Gold or Antique Gold. Once dry, go over it with a lighter color like Silver or Pewter. The darker base coat will show through, giving more visual interest.

Antiquing

For an antique finish, apply Rub n Buff as normal then use fine grit sandpaper or steel wool to gently rub and distress the surface. This removes some of the Rub n Buff and reveals the base material underneath for an aged, timeworn look. You can focus your distressing on edges and corners for a more authentic antique appearance.

Stencils and Patterns

Cut out stencils from cardstock or use store-bought stencils to create patterns with Rub n Buff. Secure the stencil and apply Rub n Buff with a sponge or brush just like paint. Lift the stencil and you’ll be left with a metallic pattern or design. Experiment with layering colors for added interest.

Maintaining Rub n’ Buff Finishes

Rub n’ Buff finishes need some care and maintenance over time to keep them looking their best. Here are some tips for protecting the finish and touching it up when needed:

To protect the finish, apply a sealant like paste wax, polyurethane, or lacquer over the Rub n’ Buff once it has fully cured (typically 24-48 hours). This helps prevent oxidation and fading over time. Reapply the sealant every 6-12 months as needed. Avoid using cleaners containing ammonia, bleach, or abrasives as these can damage the finish according to this guide.

For touching up faded or worn spots, simply apply additional Rub n’ Buff in thin layers and blend it into the surrounding finish. Remove any grime or debris first for best results. Let the touch up fully cure before sealing or wearing the surface. For badly worn finishes, sometimes it is best to remove the existing Rub n’ Buff completely with mineral spirits and reapply a fresh coat according to this source.

With proper care and maintenance, Rub n’ Buff finishes can last for many years on surfaces while maintaining their beautiful metallic sheen.

Troubleshooting

Rub n Buff can sometimes be tricky to work with, especially for beginners. Here are some common mistakes and solutions when using Rub n Buff:

Applying Too Thickly

It’s easy to apply Rub n Buff too thickly, causing an uneven or bumpy appearance. Always use a very small amount and build up thin, even layers for the best results. If you do apply too much, simply use a soft cloth to gently buff off the excess.

Uneven Coverage

When Rub n Buff dries with uneven coverage, it’s usually because the base coat underneath wasn’t smooth. Make sure to prepare surfaces properly and apply base coats evenly before using Rub n Buff. If you notice uneven coverage after drying, you can apply another thin layer of Rub n Buff.

Removing Rub n Buff

Rub n Buff is designed to have excellent adhesion. If you need to remove it, try gently buffing with steel wool or scraping with an X-acto blade. Test on a small area first to make sure you don’t damage the base material. Rubbing alcohol or nail polish remover can also help dissolve Rub n Buff.

With a bit of care and practice, Rub n Buff can create beautiful metallic finishes. Just remember to apply it sparingly in thin layers and address any unevenness while still wet. It takes some trial and error, but the effects are worth it.

Conclusion

In summary, Rub ‘n Buff is a versatile metallic wax that can be used on a variety of surfaces to achieve a distressed, vintage look. Key takeaways include:

- Rub ‘n Buff works best on non-porous surfaces like metal, glass, and hard plastics. It can be used on wood but requires extra prep.

- Smooth, glossy surfaces need to be sanded and primed first to help the Rub ‘n Buff adhere properly.

- Apply Rub ‘n Buff thinly and rub it into crevices and details with a soft cloth for an antique look.

- Seal finished pieces with a clear coat spray to prevent tarnishing and protect the finish.

- With proper prep and application techniques, Rub ‘n Buff can transform everyday objects with a beautiful metallic patina.

To learn more about using Rub ‘n Buff for DIY projects, visit their official website for technique guides and product information.