What Temperature Is Amaco Velvet Underglaze Firing?

Amaco velvet underglazes have been popular ceramic coloring products since they were first introduced in the 1960’s. Known for their saturated colors and versatility, Amaco velvets are water-based underglazes that can be used on bisqueware, earthenware, and stoneware products. They are available in a wide range of colors and are valued for giving potters vibrant options when decorating work. This article provides an overview of the recommended firing temperature range for Amaco velvet underglazes, techniques for firing them properly, and tips for getting the best results.

Recommended Firing Temperature

According to AMACO’s product specifications guide, the recommended firing temperature for Velvet Underglazes is the same as the firing temperature of the clay body being used [1]. Most mid-fire clays fire between cone 04 and cone 6, with cone 06 being a common firing temperature. Velvet Underglazes are formulated to be compatible across a wide firing range, so they can be fired up to cone 10.

Firing Velvet Underglazes at the manufacturer’s recommended temperature ensures proper melting and fusion with the clay body. Mid-range temperatures between cone 04 and cone 6 produce bright, vibrant colors and a smooth surface. Firing at higher temperatures can cause the colors to become more muted. The wide firing range allows flexibility for use on different clay bodies and at varying temperatures.

Firing Range

Amaco Velvet Underglaze can be fired anywhere from cone 018 to cone 6 (1000°F – 2200°F), though the manufacturer recommends firing between cones 06 and 04 (1828°F – 1945°F) for the best results. Firing at a lower temperature range like cone 06 will result in colors that are lighter, muted, and semi-matte. As the firing temperature increases to cone 04 and higher, the colors become more saturated and achieve the signature velvety smooth finish.

According to Amaco’s website, firing Velvet Underglaze above cone 4 (2134°F) may result in exaggerated color and underglaze pinholing.

Some ceramic artists suggest firing as low as cone 08 (1646°F) for a chalkier pastel look or higher between cones 2 – 3 (2192°F – 2205°F) for brighter colors if you don’t mind sacrificing the signature velvet finish.

Firing Techniques

There are a few different firing techniques you can use when firing Amaco velvet underglaze:

Fast Firing: You can fire velvet underglaze using a fast fire approach, with rapid heating up to the peak temperature, a short hold, and then rapid cooling. Pieces fired this way will have brighter, more vibrant colors from the underglaze. However, fast firing can cause issues with cracking or crazing in the glaze if the clay body and glaze formulation are not optimized for it. Fast firing works best for simple, thin shapes without glazes over the underglaze.

Slow Firing: A slower, gradual firing schedule with extended holds at intermediate temperatures allows gases to escape and reduces thermal shock. This can help prevent defects like pinholing or cracking. The slower cooling also allows colors to develop fully. However, the colors may end up slightly more muted compared to fast firing. Slow firing works well when applying underglazes under a transparent glaze.

The Amaco website recommends firing most velvet underglazes to cone 06-04 for brighter colors or cone 06-6 for softer, more blended effects. The firing schedule should be adapted to the specific clay body, glaze, and kiln type to achieve good results.[1]

Kiln Type

The type of kiln used to fire Amaco velvet underglazes can impact the final results. Amaco underglazes are formulated to be fired in both electric and gas kilns, but there are some differences to be aware of.

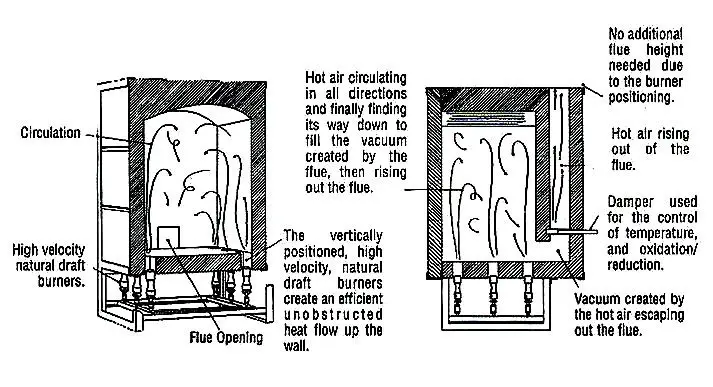

In an electric kiln, the temperature climbs steadily and evenly throughout the kiln chamber. This allows the underglaze to mature slowly and evenly during the firing. Electric kilns provide a very controlled and predictable atmosphere.

Gas kilns tend to have more variability in temperature from top to bottom and side to side. The flames can also introduce more oxygen to certain areas of the kiln, creating a more oxidizing atmosphere. This can impact the final color achieved with the underglaze. Reds and browns may become more muted in a gas kiln firing. Careful kiln placement and monitoring of cones is important when firing in a gas kiln.

For best results, Amaco recommends firing in the cone 06-04 range for their velvet underglazes. This helps ensure proper melting, adhesion, and final color development regardless of kiln type. Longer soak times can also help mitigate the differences between electric and gas kilns when firing velvet underglazes.[1]

Glaze Chemistry

The chemical composition of Amaco velvet underglaze affects the ideal firing temperature and performance. According to the SDS, velvet underglazes contain frit, clay, pigments such as chromium oxide, and small amounts of silica. The frit is a mixture of silica, borax, and soda ash that has been melted together and ground into a fine powder. This allows the glaze to melt and flow at a lower temperature compared to a glaze made solely with clay. The clay provides adhesion to the biscuit while the pigments add color. Silica, which makes up a significant portion of the frit composition, has a high melting point that influences the ideal firing range. Overall, velvet underglaze is formulated to melt and develop a smooth, matte surface at cone 06.

Testing Your Pieces

When working with a new glaze or underglaze like Amaco velvet, it’s important to test pieces to ensure the products are firing properly. There are a few key ways to evaluate if your fired test tiles of velvet underglaze are successful:

Color – Compare the fired color to the manufacturer’s color chart or sample tiles. Velvet underglaze colors should remain fairly true through multiple firings, with only slight shifting in certain hues. If the color is dramatically different, the firing temperature or chemistry may need adjusting.

Texture – Properly fired velvet underglaze will have a smooth, matte velvet finish. Overfiring can cause it to become pitted or rough. An overly glossy or shiny surface likely indicates underfiring.

Durability – Check that the underglaze adheres well to the clay body by touching and lightly scratching the surface after firing. Flaking or scratching off means it did not mature enough in the kiln.

Test pieces multiple times, adjusting the kiln temperature in small increments to hone in on the optimal cone for your clay body, glaze, and underglaze combination according to this guide. Keep good notes on each test firing for comparison.

Troubleshooting

Amaco velvet underglaze can have firing issues if not properly prepared and fired. Some common problems include the glaze crawling, crazing, shivering, or peeling away from the underglaze. This is often caused by incompatible glaze and underglaze chemistry, firing too hot or cold, or applying the underglaze too thickly.

To avoid these issues, carefully follow the manufacturer’s instructions for firing temperature and glaze compatibility. Use glazes designed for the 06-6 cone firing range if firing Velvet to maturity. Slowly ramp up the temperature and allow sufficient hold time. Apply the underglaze in thin, even coats and do not overload the surface. Bisque firing before applying underglaze can also help improve adhesion.

If crawling or shivering occurs, try using a thicker application of a compatible glaze. For crazing, use a thinner glaze layer. Adjust the firing schedule and glaze if underglaze appears faded or washed out. Test compatibility of new glaze and underglaze combinations on test tiles before applying to finished wares. With careful application and firing, Amaco velvet underglaze can produce vibrant durable results.

Safety Considerations

When working with Amaco velvet underglazes, it is important to take proper safety precautions. According to Sheffield Pottery, you should always work in a well-ventilated area when using glazes and underglazes. Wearing a N95 respirator mask is recommended to avoid breathing in any dust or fumes.

It’s also important to wear proper protective equipment like goggles, gloves, and an apron when handling underglazes. The velvet underglazes contain chemicals that can irritate eyes and skin. Avoid contact with eyes and wash hands thoroughly after use.

Follow all manufacturer safety recommendations when mixing, applying, and firing velvet underglazes. Never eat or drink while working with underglazes. Avoid generating dust when mixing dry materials. Handle wet underglazes carefully to avoid spills or splashes.

Properly store underglazes in sealed containers out of reach of children. Dispose of all underglaze waste according to local regulations. With proper safety precautions, Amaco velvet underglazes can be used safely by artists of all levels.

Conclusion

To sum up, Amaco velvet underglazes are typically fired at a temperature of 04 cone or 1652°F (900°C). When applying velvet underglazes, it’s important to follow the manufacturer’s recommendations for firing to achieve the desired results. The ideal firing range is between cone 06 and cone 02, which is 1587°F to 1652°F (860°C to 900°C). While you can fire at higher temps, this may cause the velvet finish to become more satin-like. The key is doing test tiles first to determine the optimal firing schedule for your pieces, kiln, and desired aesthetic. With proper firing, Amaco velvet underglazes produce a beautiful rich, velvety matte surface.