What Tool Can I Use To Cut Tiles?

Cutting tiles to the proper size and shape is an essential part of any tile installation project. There are a variety of tools available to cut ceramic, porcelain, stone, glass and other types of tile materials. Selecting the right cutting tool for the job will ensure precision cuts and a professional looking finished product.

Manual tile cutters, also known as tile nippers or nipper pliers, provide a basic and inexpensive tile cutting option. Wet saws utilize a water-cooled diamond blade to generate clean and accurate cuts in tile. Angle grinders with diamond blades can cut curves and notches in tile. Tile scoring tools and oscillating multi-tools are useful for detailed cuts.

The type of tile, required cuts, and experience level of the user are all important factors when determining the best tile cutting tool. With the proper cutting technique, most tiles can be shaped and fitted perfectly using one of these tile cutting tools.

Manual Tile Cutters

When it comes to cutting ceramic, porcelain or glass tiles by hand, having the right manual tile cutting tool is essential for precise and clean cuts. Here are some of the most common manual tile cutters:

Tile nippers are plier-like tools used to nibble away at tile to remove small irregular pieces or for detailed cutting. They can create rounded edges or small holes in tile. Quality tile nippers like the Montolit Piuma tile nippers help provide smooth controlled bites.

Tile scribers are similar to utility knives but with a rotating carbide scoring wheel. They are used to score and snap tiles by applying pressure along the scored line. Top options like the Montolit cutters allow scoring straight lines or tight curves.

A tile cutter hand tool consists of a scoring wheel and a cutting pad and allows for adjustable scoring depth. Heavy duty models like the Sigma Technica tile cutters deliver extreme cutting force for even the hardest tiles. Handheld tile cutters are portable, fast and can make extremely precise and accurate cuts.

Wet Saws

Wet saws, also known as tile saws, are a popular power tool for cutting ceramic, porcelain, stone, and glass tiles. They use a diamond-tipped blade that is continuously cooled by a stream of water to reduce friction, heat, and dust when cutting tiles. This allows wet saws to make clean, precise cuts through hard materials without cracking or chipping them.

Diamond blade wet saws are designed specifically for cutting tile and stone. The diamond-tipped blade has small diamond segments embedded around the edge that do the actual cutting. The diamonds grinding against the tile material create a lot of friction and heat, which is why cooling the blade with water is so important.

Some of the pros of using a wet saw include:

- Makes straight, accurate cuts, especially for mitered edges.

- Cuts hard materials like porcelain and stone without cracking.

- Water cools and lubricates the blade reducing dust and overheating.

- Suitable for cutting curves and shaped tiles.

- Cuts faster than a manual tile cutter.

Some of the downsides include:

- More expensive than manual tile cutters.

- Requires a water hookup.

- Not as portable as manual cutters.

- Learning to use one properly takes some practice.

When using a wet saw, it’s important to follow safety precautions. Always wear eye protection and a dust mask. Keep fingers away from the spinning blade and make sure the guard is in place before starting any cuts. Operate the saw according to manufacturer’s instructions and unplug it when changing blades or making adjustments.

With the proper precautions, wet saws allow tile installers to accurately cut even the hardest stones and tiles with a smooth, polished edge (Tile Tracker).

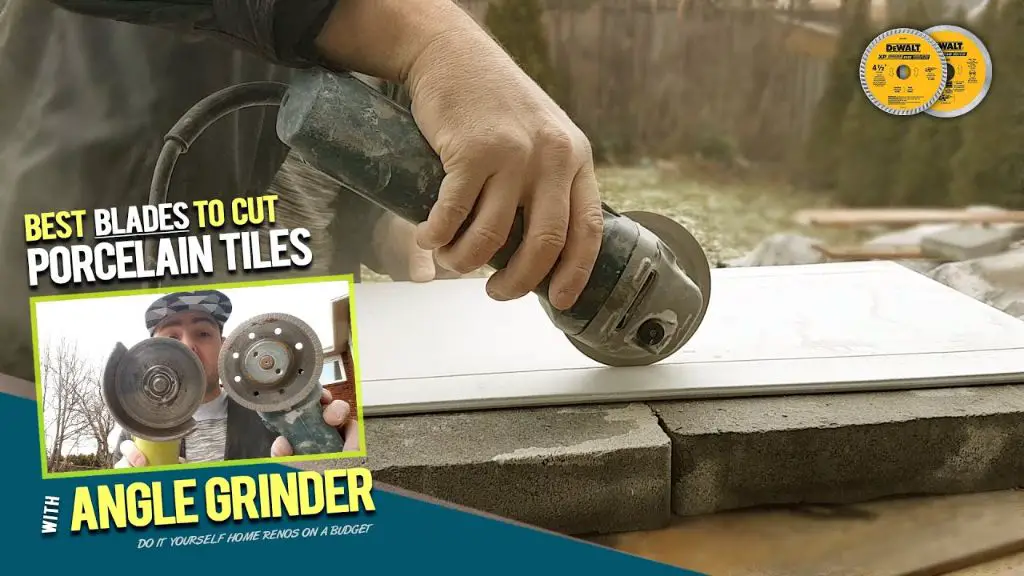

Angle Grinders

Angle grinders with diamond blades are a popular option for cutting tiles. They utilize a rotating disc that spins at high speeds to slice through tiles cleanly. Diamond blades are made by bonding small industrial grade diamonds to the outer edges of the cutting disc. The diamonds abrade away and cut through hard materials like ceramic, porcelain, and stone tiles without causing cracks or chips (1).

Angle grinders with diamond blades have several pros. They offer fast and precise cuts, and can cut curves, notches, and holes in tiles that other tools may struggle with. Angle grinders are highly versatile and can be used for other applications like grinding and sanding. They are also relatively affordable compared to other tile cutting tools.

On the downside, freehand cutting with an angle grinder takes practice to master. It can be difficult for beginners to make perfect straight or curved cuts. The high-speed spinning discs also produce a lot of debris and dust that requires safety precautions. Wearing eye protection, a dust mask, ear protection, and gloves is essential when using an angle grinder. Working carefully and steadily while letting the diamond blade do the cutting is key to avoiding cracks or chips in tiles.

Tile Scoring Tools

Tile scoring tools, also known as tile cutter wheels or carbide scoring tools, are a popular option for cutting tile. They work by using a small, hard cutting wheel to score the surface of the tile along the desired cut line. This scores or weakens the tile so it can then be snapped cleanly along the line.

Carbide scoring wheels are extremely hard and durable, allowing them to cut through ceramic, porcelain, and natural stone tiles. The wheels are mounted on a handle or tile cutter tool. Many manual tile cutters have built-in carbide wheels. The wheels can also be purchased separately as handheld tools.

Tile scoring tools have several advantages:

- They are inexpensive and have a low initial investment compared to other tile cutting tools.

- The scoring and snapping method avoids messy tile dust or water.

- They can quickly score curves or notches.

- Replacement scoring wheels are inexpensive.

The disadvantages of tile scoring tools include:

- Difficulty making straight or precise cuts, especially on large tiles.

- Labor intensive scoring and snapping process compared to cutting.

- Not effective on extremely hard stones like granite.

- Thickness variations in tile can lead to uneven breaks.

Overall, tile scoring tools are best for small DIY projects using typical ceramic tiles up to 12″ x 12″. For frequent tile cutting or working with large format tiles, a wet saw or angle grinder may be a better choice.

(Montolit, professional tile cutting tools since 1946. www.montolit.com. Accessed March 1, 2023.)

Oscillating Multi-Tools

Oscillating multi-tools are a versatile option for cutting tiles. These tools have a rapid oscillating blade that can cut through tile and other materials. They are handheld and plug into an electrical outlet.

Oscillating tools used for tile cutting have a diamond grit blade specifically designed for tile. The rapid oscillations of the blade allow it to smoothly cut curves and holes in tile. Unlike a circular saw blade, the oscillating blade won’t chip tile edges.

The main advantages of oscillating tools are their ability to make detailed curved or angled cuts and cut holes in tile. They can access tight corners and spaces. The small blade allows for great precision and control. Oscillating tools are also quite affordable compared to other electric tile cutting tools.

The downsides are that they cut more slowly than other electric tools. The blade wears down over time and needs frequent replacement. Oscillating tools also produce a lot of dust when cutting tile or stone.

Top brands for oscillating multi-tools include Fein, Rockwell, Dewalt, and Bosch. Look for a model with an adjustable speed dial and tool-less blade change. Variable speeds allow different materials to be cut smoothly. Easy blade changes make replacing the blade quick and simple.

Choosing the Right Tile Cutter

When choosing a tile cutter, there are a few key factors to consider:

The type of tile material you’ll be cutting – ceramic, porcelain, glass, or stone tiles require different cutting methods and tools. Ceramic and porcelain tiles up to 15mm thick can be cut with manual cutters, while thicker stone and glass tiles often require a wet saw (Source).

The size and thickness of your tiles – For small mosaic tiles, a handheld cutter is sufficient. Larger tiles or thick natural stone require more powerful saws. Most manual cutters can cut tiles up to 20” long and 1⁄4” thick (Source).

Straight or shaped cuts – Simple snap tile cutters are great for straight cuts. Curved, L-shaped, or outlet cuts require specialty cutters or wet saws.

Cutting frequency – Occasional DIY jobs only require a basic manual cutter, while professionals will want a high-capacity model. Wet saws are ideal for large jobs.

Your budget – Manual tile cutters range from $50-500. Wet saws start around $100 for basic models, up to $2000 for commercial grade.

Cutting Tile with Precision

When installing tile, it’s crucial to cut the tiles precisely to achieve clean, professional results. Here are some tips for making accurate straight cuts:

Use a tile cutter – Tile cutters with carbide scoring wheels are ideal for making straight cuts. Position the tile on the cutter bed and align the score mark on the tile with the cutting wheel. Apply firm, even pressure as you push the handle and cut through the tile.

Use tile spacers – Small plastic spacers placed between tiles ensure evenly spaced grout lines. After marking tiles for cutting, leave the spacers in place while you cut. This helps keep the tiles steady and aligned for a straight cut (Source).

Cut several tiles together – Stack 2-3 tiles on top of each other and cut them simultaneously. The combined thickness makes it easier to cut straight compared to a single tile.

Use a straightedge – For freehand cutting with a snap cutter or grinder, use a straightedge as a guide. Align it perpendicular to the cut line to ensure the cut stays straight.

Mark both sides – Mark the desired cutting line on both the front and back of the tile. This allows you to ensure the cut line stays aligned while cutting.

Cut slowly and smoothly – Rushing through cuts can result in crooked lines or chipping. Cut steadily with smooth, consistent pressure for the best results.

Cutting Curves and Holes

Cutting curves and holes in tile requires some specialized tools and techniques. Using the right approach helps ensure clean, precise cuts.

Hole Saws

A tungsten carbide or diamond-grit hole saw attached to a drill allows cutting clean circular openings in tile. Hole saws come in different diameters. Center the hole saw over the desired location and drill slowly with light pressure. Let the tool do the work. Apply water to lubricate and cool the blade.

Contour Grinding

For freehand curved cuts, an angle grinder with a diamond blade excels. Mark the contour on the tile first. Grind along the line, letting the turning blade contour the curve. Grind slowly and smoothly. Wear eye protection and a dust mask.

Nipping

Use handheld tile nippers to nibble away at the tile for detailed curved cuts and openings. Nippers easily remove small fragments of tile along an irregular cutline. First score the cut with a tile cutter, then use the nippers. Be patient and take small nibbles to achieve a clean edge.

Tile Cutting Safety

When using any tool to cut tile, it’s crucial to follow safety precautions to avoid injuries. Proper eye protection should always be worn to guard against debris that can fly when cutting tile. Safety glasses with side shields or goggles are recommended. Ear protection like earmuffs or earplugs will protect hearing from prolonged exposure to cutting noises. A NIOSH-approved dust mask will prevent inhaling fine tile particles into lungs. An N95 respirator is best for dry cutting tile that creates silica dust.

The tile cutting area should be kept free of clutter and trip hazards. Cords for tools should be neatly organized and tile pieces cleared frequently to maintain a clean workspace. For wet saws, electrical cords and outlets should be dry and protected from water. Using a GFCI outlet provides protection in case of electric shock. Hands and fingers should be kept at a safe distance from the cutting blade at all times. When handling or adjusting the tile, tools should be powered off completely.

Following safe practices when using tile cutting tools is critical for avoiding eye injuries, respiratory issues, lacerations, electrical shocks, slips, and trips. Protecting oneself with proper safety gear and maintaining an organized, debris-free workspace helps maximize safety and precision when cutting tile. For more specific tile cutting safety tips, check out this article from Century Tools.