What Tool Is Used To Cut Circles In Wood?

This article will provide an overview of the most common tools used to cut circular shapes in wood. Creating circular cuts is an essential woodworking skill needed for many projects, from simple decorations to complex furniture pieces. Circles not only add visual interest through their curved shape, but also serve functional purposes like creating holes for dowels or forming rounded edges. Understanding the capabilities and limitations of the available circle cutting tools will help woodworkers select the right option for their specific needs and material.

We will examine both manual tools that rely on the skill of the woodworker as well as powered machinery that can produce consistent results. Key factors in choosing a circle cutting tool include the diameter needed, type of wood, desired precision, and individual skill level. This guide covers everything from quick DIY options to professional woodshop tools. Whether you are cutting occasional small holes or mass producing identical pieces, there is a circular cutting tool suited for the job.

History of Circle Cutting Tools

Tools for cutting circles in wood have evolved significantly over time. Some of the earliest circle cutting tools were simple handheld devices like compasses. The ancient Greeks and Romans used a simple compass with one leg pointed and one leg with an attached pencil to scribe circles (Source: Appendix 6: Evolution of Woodworking’s “Cutting Edges”). This allowed them to mark circular cuts, but did not actually cut the wood.

In the Middle Ages, carpenters began using frame saws and bow saws to cut curved shapes and circles in wood (Source: The Historical Development of Basic Woodworking Hand Tools). While tedious, these manual saws allowed more precise and accurate cuts than previously possible. This evolution from marking circles to actively cutting them by hand represented a major advancement.

Powered circle cutting tools emerged in the late 18th and early 19th centuries with the invention of the circular saw. Some sources credit Tabitha Babbitt as inventing the first circular saw around 1813 (Sources: Appendix 6, Historical Development of Woodworking Hand Tools). This automated the circle cutting process and greatly increased productivity and precision.

Modern circle cutting tools like jigsaws, scroll saws, bandsaws, routers, and laser cutters have further improved efficiency, accuracy, and capabilities for cutting circles. But the origins trace back to simple manual devices like the compass.

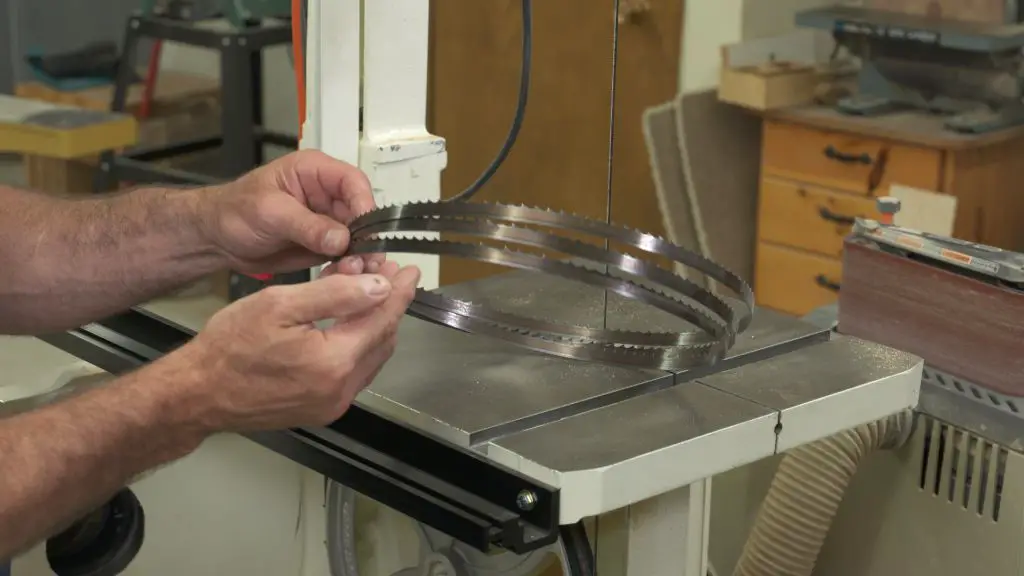

Bandsaws

A bandsaw is a saw with a long, sharp blade consisting of a continuous band of toothed metal stretched between two or more wheels to cut material (Cutting Circles on the Band Saw). The wheels allow the blade to be rotated around a central driveshaft, providing continuous downward or upward motion to cut through wood or other materials. Bandsaws are available in horizontal and vertical designs.

What makes the bandsaw ideal for circle cutting is its thin, pliable blade. The blade’s adjustability allows the user to curve and guide the blade to cut smooth circles and arcs. Most bandsaws have blade guides that can be customized to the radius of the circle being cut. The blade guides support the blade throughout the curved cut to achieve the desired shape.

There are several types of bandsaws appropriate for circle cutting. Stationary cabinet saws allow for larger capacity cuts. Benchtop portable models provide the same precision cutting ability in a smaller footprint. Residential hobbyist models are lightweight and easy to operate. Bandsaws designed specifically for woodworking provide optimal performance for cutting curves in lumber or other wood materials.

Choosing the right bandsaw blade is key for clean, accurate cuts. Standard blades work for most curved cuts. But for tighter radiuses, a narrow blade of 1⁄4″ – 1⁄2″ is recommended. Skip tooth blades with spaces between cutting teeth can prevent jamming in dense woods or plastics. A bandsaw’s blade guides usually include adjustments for tracking the blade’s drift to maintain the desired cut shape.

Scroll Saws

Scroll saws are a specialized power tool used for making precise, intricate curved cuts in wood, metal, plastic, and other materials. Their fine, thin blades allow for tight turning radiuses down to just a fraction of an inch. This makes scroll saws ideal for cutting detailed shapes, holes, and—with care and technique—circles.

Scroll saw blades are held vertically and oscillate rapidly up and down to saw through material. The fineness of a scroll saw blade allows it to turn or scroll through a cut by carefully feeding the material into the blade’s path. This is ideal for creating flowing curves, inside cutouts, lacework, fretwork and other scrolling effects.

Scroll saws are designed to cut relatively thin material, usually under 2 inches thick. They hold the workpiece stationary while the blade moves, unlike a band saw where the work moves while the blade stays still. The key components of a scroll saw are the blade holders, blade tensioning, and a table to support the work.

There are plain-end or pin-end scroll saw blades for different purposes. Pin-end blades are easier to change quickly. Scroll saws use blades in standard lengths (e.g 5 inch) and sizes from around #2 through #9, with higher numbers being finer blades. Choosing the right size and type of blade is important for smooth, splinter-free cuts.

With the proper blade and techniques, scroll saws excel at cutting precise circles and curves in wood. A gentle sawing motion is used to follow a line or pattern. Relief cuts help for tight radiuses. Inside cutouts require piercing starter holes first. It takes practice to master intricate scroll saw work, but the results can be quite impressive.

Jigsaws

Jigsaws are a versatile portable power tool that can be used for cutting circles and other curved shapes in wood. They have a thin, reciprocating blade that moves up and down rapidly, allowing the user to guide the blade along a line. What makes jigsaws uniquely suited for cutting circles is their orbital setting.

Most jigsaws have a lever or dial that adjusts the orbital setting. This controls how much the blade moves back and forth laterally while it’s reciprocating up and down. When set to zero, the blade moves straight up and down. As you increase the orbital setting, the blade starts moving in an elliptical pattern, oscillating slightly side-to-side as it cuts. This orbital action allows the jigsaw to cut gentle curves and circles more easily in the workpiece.

There are various jigsaw blade options depending on the thickness and type of material being cut. For cutting circles in wood, a blade with larger teeth (around 10 TPI) is recommended to clear out saw dust and reduce binding. Scroll cut blades are designed for making delicate curved cuts with tighter radii. Other specialty blades can cut metal, PVC, and ceramic tiles. Choosing the right jigsaw blade for the application is key to making smooth circular cuts.

Hole Saws

Hole saws are cylindrical saws with a drill bit in the center and teeth around the outside edge. The teeth cut into the material to remove a plug of material, creating a circular hole.

Hole saws come in a range of sizes, generally starting around 1/4″ in diameter up to several inches or more depending on the model. Larger hole saws, up to 12″ or greater, are available for cutting big diameter holes. The most common sizes are around 1″ to 3″ for typical applications like installing door hardware or plumbing pipes.

The cylinder is made of steel or bi-metal, combining high speed steel teeth with a steel backing for durability. Carbide grit hole saws are designed for masonry and tile applications. Diamond hole saws have small diamond chips along the cutting edge for cutting ceramic tile or glass.

Compared to a drill bit that bores a hole, the hole saw’s cylindrical shape with teeth efficiently cuts out the entire circle in one pass. This saves time and effort compared to drilling multiple holes around a perimeter to cut out a circle.

Compasses

A traditional tool for scribing perfect circles in wood is the compass. These wooden compass tools consist of a beam or straightedge with points mounted at each end. One point is fixed in place, while the other end has an adjustable point that can slide along the beam. The fixed leg of the compass is positioned at the center point of the desired circle. By rotating the compass while keeping the fixed leg in place, the adjustable point scribes a perfect circle into the wood 1. The circle can then be cut out using a bandsaw, jigsaw or other saw. The beam compass allows for cutting circles up to around 4 feet in diameter.

For larger diameter circles, a trammel compass can be used. This tool has an adjustable beam length as well as an adjustable point for scribing circles up to 8 feet or more in diameter. Trammel compasses are commonly used in boat building and other large woodworking projects.

Modern circle cutting tools also include compass attachments for routers and other power tools. These allow the woodworker to cut a perfect circle by attaching a pivot pin and adjustable arm to the base of a router. Some jigsaws and scroll saws also accept compass attachments for clean and accurate circular cuts.

CNC Routers

CNC routers are computer numerically controlled machines that can be programmed to cut a variety of shapes, including circles, with precision and accuracy (WoodWeb). CNC routers are available in a range of sizes, from small hobby models to large industrial machines. The size of the router will determine the maximum size of the circular cut it can produce. For example, a desktop CNC can typically cut circles up to 24″ in diameter, while industrial models can cut circles many feet across.

CNC routers use CAD/CAM software to convert digital designs into machine code that controls the router. Simple circles can be programmed directly, while more complex circular patterns may need to be designed in CAD first before converting to toolpaths. The program code guides the router along the desired path to cut the material underneath. CNC software allows for adjustments to the cut depth, speed, and other parameters. Troubleshooting may be needed for consistently accurate circles, as cheaper machines can sometimes distort circles into oval shapes (OpenBuilds). Upgrading mechanical components, tweaking settings, and using high quality bits can improve circular cutting accuracy on CNC routers.

Laser Cutters

Laser cutting is a technology that uses a powerful, focused laser beam to cut through materials like wood, plastic, and metal. The laser beam is directed at the material, which heats it up and burns, melts or vaporizes the material along the cut line.

Laser cutters are capable of cutting precise circles in wood through this laser cutting process. The user can program the laser cutter with the dimensions of the circle, and the laser will burn through the wood following that circular pattern. Laser cutters are extremely accurate, with tolerances down to thousandths of an inch, allowing precise circular cuts.

There are different types and sizes of laser cutters available. Smaller desktop laser cutters like the Glowforge or X-Carve are suitable for cutting wood circles less than 1 inch thick and 2 feet in diameter. Larger industrial laser cutters can cut thicker wood up to 6 inches thick and circles with diameters of 4 feet or more. CO2 and fiber lasers are commonly used in wood laser cutting.

Compared to manual tools like jigsaws or scroll saws, laser cutters provide extremely precise circular cuts in wood, with excellent repeatability. They can cut large diameter circles not feasible with manual tools. The ability to program cut patterns makes laser cutting circles very easy. Limitations include material size capacity, depth of cut, and higher equipment costs compared to manual tools.

Conclusion

When it comes to cutting circles in wood, woodworkers have a variety of effective tool options to choose from. As discussed, bandsaws, scroll saws, jigsaws, hole saws, compasses, CNC routers, and laser cutters can all produce clean, accurate circular cuts. The tool that will work best depends on the size of the circle, the thickness and type of wood being cut, the precision needed, and other factors.

Smaller circles and intricate curved details are often best achieved with a scroll saw or jigsaw. Larger diameter circles in thicker stock can be cut efficiently with a bandsaw or hole saw. For maximum precision, a laser cutter is ideal but comes at a higher cost. And a simple compass remains a cheap, easy option for rough circular cuts.

No matter the woodworking project, there is likely a circular cutting tool well-suited to the application. With knowledge of the various options and their capabilities, woodworkers can choose the optimal tool for cutting circles to their exact specifications.