What Type Of Clay Is Good For Making Earthenware?

Earthenware is a type of ceramic that is fired at lower temperatures (around 1700-2100°F) compared to other ceramics like stoneware and porcelain. It has been used for thousands of years to create practical and decorative objects like pottery, tiles, and sculptures. Some defining characteristics of earthenware are that it is opaque, porous, and soft. The lower firing temperature allows earthenware clays to retain more of their natural colors and makes glazing easier.

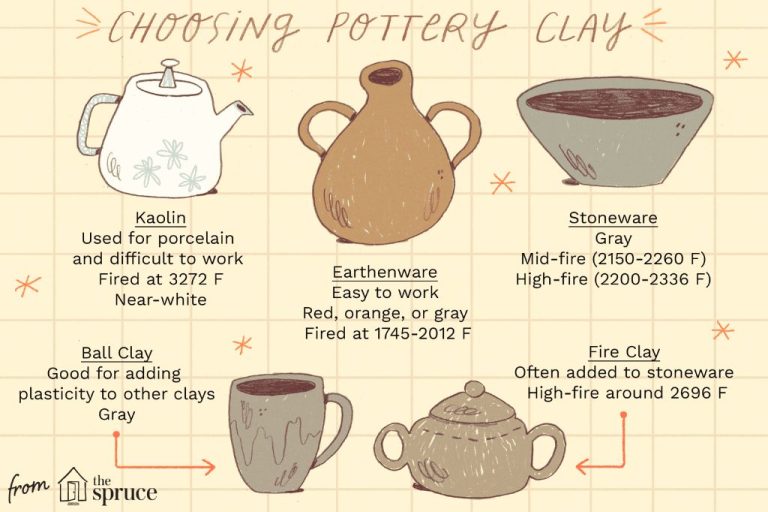

The composition and properties of the clay determine whether it is suitable for making earthenware. Three main types of clay can be used: earthenware clay, stoneware clay, and ball clay. Earthenware clays are low-fire clays that vitrify (become glass-like) at earthenware temperatures. Stoneware clays have longer firing ranges. Ball clays help improve plasticity and workability. The ideal clay body has the right blend of plasticity for throwing and shaping, strength after firing, and firing range. The clay must also be able to absorb water. These factors allow the clay to be turned, joined, decorated, and fired into earthenware.

Some key characteristics that make clay good for earthenware are plasticity and workability, low shrinkage, low firing temperature, and absorption. The clay needs to be smooth and elastic when wet so it can be shaped. It should not shrink too much when drying to avoid cracking. The firing range needs to remain under 2100°F. And the clay must be porous after firing to absorb water and glazes.

Clay Composition

Clay is a naturally occurring material composed primarily of fine-grained minerals, which is plastic when wet. The difference between primary and secondary clays is that primary clays are found at the original site of formation, while secondary clays have been transported from the parent rock and deposited elsewhere.

The mineral composition of clay includes hydrated alumina silicates, iron, magnesium, alkali metals, and alkaline earths. The chemical composition varies but generally consists of silica, alumina, water, and other minerals. The amount of these elements influences the clay’s properties and how it responds in firing. The particle size of clay particles is very small, typically less than 2 micrometers. The smaller the particle size, the more plasticity the clay body exhibits when mixed with water.

Plasticity refers to a clay’s ability to be shaped without cracking or crumbling. Clay becomes plastic and workable when its absorbing water interacts at a molecular level with the clay particles. Plasticity makes clay an excellent material to craft earthenware and ceramic objects.

Low-Fire Earthenware Clays

Low-fire earthenware clays are some of the most commonly used clays for handbuilding and wheel throwing. They are characterized by their low maturing temperature, typically firing at cone 04-06 which is approximately 1922-2102°F (1050-1150°C). This makes them ideal for firing in a simple electric kiln.

Earthenware clays contain varying amounts of clay minerals as well as non-plastic inclusions that affect their workability, drying time, and fired color. They tend to be porous when fired, allowing absorbed water to evaporate from the clay body. Common types of earthenware clay include:

– Red Earthenware: Fires to a red or orange color due to the presence of iron oxide. It has good plasticity and is commonly used for flower pots, tiles, and brick.

– Terracotta: An ancient form of earthenware clay that fires to a distinctive orange/red color. It’s less plastic than other earthenware clays but has good workability.

High quality earthenware clays are mined and produced commercially around the world. In the US, Tennessee and Georgia are noted sources. Italy is renowned for its terracotta clays. When selecting an earthenware clay, it’s important to consider the plasticity, fired color, and maturation temperature for your specific project needs.

Workability

The workability of a clay refers to how easily it can be manipulated and shaped. When selecting clay for earthenware, you’ll want to consider factors like plasticity, stiffness, shrinkage, and water content.

Plasticity refers to how flexible and malleable the clay is. More plastic clays are easier to wedge, roll, throw, and shape without cracking. However, extremely plastic clays can be too soft and may not hold their form well.

The stiffness of the clay determines how well it will hold up vertically when thrown on the wheel. Stiffer clay requires more force but will not slump as easily. The stiffness should match your skill level.

Shrinkage refers to how much the clay body will reduce in size from wet to dry and during firing. Higher shrinkage requires more care when drying to prevent cracks but can result in a denser final product.

The right water content is crucial for proper wedging and workability. Wedging blends water evenly throughout the clay and removes air pockets. Well-wedged clay has a smooth, uniform plasticity. Under-wedged clay will dry unevenly and be prone to cracking and exploding.

Firing Temperature

The typical firing range for earthenware clay is between 1750-2100°F. Firing temperature has a significant effect on the physical characteristics of the clay body. At lower temperatures, the clay remains porous and able to absorb water. As the temperature increases, the clay vitrifies and becomes denser, harder, and less porous. Maximum absorption occurs between 1750-1850°F. For functional ware that will hold liquids, lower firing temperatures are recommended. For decorative pieces, higher firing temperatures can improve durability and stability.

Glazes

Glazes serve multiple purposes for earthenware pottery. First and foremost, glazes provide an impervious coating that makes earthenware non-porous and waterproof. Without a glaze coating, unglazed earthenware would soak up water and leak. Glazes also add decorative colors, textures, and effects to the final fired surface.

The most common glazes used on earthenware clay are low-fire glazes, typically matte glazes. These include a range of colorful glazes from bright primaries to earth tones, as well as clear glazes. Low-fire glazes melt and fuse to the clay body at temperatures between cone 04 (1945°F) and cone 3 (2165°F). Other specialty glazes like crackle glazes, metallic glazes, and raku glazes are also popular for creating unique decorative effects on earthenware.

Clay Body Recipes

When making your own clay body recipes for earthenware, you’ll want to use a blend of different clays to achieve the right balance of plasticity, strength, porosity, and firing temperature. Here are some example recipes to try:

Simple Earthenware Clay

50% ball clay

25% kaolin

25% feldspar

This recipe uses a simple 1:1:1 ratio of ball clay, kaolin, and feldspar. The ball clay provides plasticity, the kaolin gives whiteness and strength, and the feldspar acts as a flux to lower the firing temperature. This recipe can be used for handbuilding or wheel throwing.

Smooth Earthenware Clay

60% ball clay

20% kaolin

15% silica

5% feldspar

The higher percentage of ball clay creates a very smooth, plastic clay that’s great for throwing thin-walled pieces. The silica adds strength to the clay body while keeping it smooth and consistent. Smaller amounts of kaolin and feldspar provide whiteness and lower the firing temperature.

Porcelain-Like Earthenware

35% ball clay

35% kaolin

25% silica

5% feldspar

This recipe uses higher percentages of kaolin and silica to create a smooth, strong clay with whiteness resembling porcelain, while still firing at earthenware temperatures. The ball clay keeps it plastic enough for throwing and handbuilding.

Slip Casting

Slip casting is a common method for forming earthenware pieces using liquid clay. It offers several benefits for creating precise, thin-walled pieces.

The main advantage of slip casting is that it allows for consistency and uniformity in shapes and wall thickness. The liquid clay, called slip, is poured into a plaster mold and allowed to sit until a layer forms against the mold walls. As the water gets absorbed into the porous plaster, it leaves an even clay layer in the mold. This makes it easy to achieve thinner, delicate forms.

Slip casting enables more intricate shapes and details than may be possible with handbuilding techniques. The liquid clay flows evenly into every crevice of the mold. Molds can be made from various materials like plaster, clay, rubber or metal. Plaster molds are the most common because they are inexpensive and absorb water well.

To slip cast a piece, first the mold is prepared by coating it in a release agent so the piece can be removed cleanly. The mold is filled with slip, usually to a overflow level. After a short time, the desired thickness of clay remains in the mold as the plaster draws out the water. The excess slip is poured out of the mold. The clay piece is left to dry partially in the mold before removal. Once stiffened but still moist, the piece can be trimmed and refined before drying and firing further. Multiple castings can be made from the same mold.

With some practice, slip casting allows both speed and refinement in forming earthenware suitable for vases, bowls, cups and other vessels. The ability to repeatedly cast uniform pieces makes it ideal for producing multiples and sets.

Wheel Throwing Earthenware

When throwing earthenware on the pottery wheel, it’s important to keep in mind the properties of earthenware clay. Earthenware has good plasticity which makes it easy to center and open up on the wheel. However, it also has high shrinkage and can be prone to cracking and warping.

Here are some tips for successfully throwing earthenware:

- Center the clay well and open it up slowly to reduce stress on the walls

- Keep walls an even thickness throughout the piece

- Avoid making pieces with overly thin walls that could collapse

- Let pieces stiffen slightly before final shaping to avoid distortion

- Use rib tools and sponges, rather than excess water, for smoothing

- Compress the clay well before lifting pieces off the wheel

When drying and firing earthenware, special care must also be taken:

- Dry pieces slowly and evenly to prevent cracking and warping

- Bisque fire carefully according to the clay body instructions

- Glaze and fire pieces according to the glaze specifications

- Use test tiles to dial in the correct glaze thickness and firing schedule

- Fire on the low end of the recommended range for the clay and glaze

- Allow kiln to cool slowly and evenly after firing

With some practice and care, beautiful wheel thrown earthenware pieces can be achieved.

Conclusion

When choosing the right clay for earthenware, the key considerations are workability, firing temperature, and glazing. The best clays for earthenware tend to be low-fire red earthenware clays or white earthenware clays. These clays are smooth and elastic, easy to work with, and fire between cone 04 and cone 2 for bright colors and durable pieces.

Some of the top recommended earthenware clays are:

- Redart clay – An excellent all-purpose red earthenware clay that throws well on the wheel and handbuilds easily. Fires to a bright red-orange color.

- Helios Sculpture Clay – A smooth, versatile white earthenware that’s great for handbuilding and sculpting. Can be fired up to cone 5 for increased durability.

- Valentines Clay – A red-burning earthenware with excellent plasticity. Throws well on the wheel and fires to a rich red.

- Speckled Buff – A speckled earthenware clay that fires to a warm buff color. Good plasticity and workability.

For the best results with earthenware, choose a clay body that matches your desired working and firing methods. Test different clays to find one with the right blend of plasticity, texture, and firing color for your projects.