Where Can We Find Clay?

Clay is an important group of minerals that can be found all over the world. While clay may seem like ordinary dirt to most people, it has a wide variety of uses that make it an essential natural resource. Knowing where to find clay deposits and how to extract them is crucial for many industries and applications ([https://geologyscience.com/minerals/clay-minerals/?amp](https://geologyscience.com/minerals/clay-minerals/?amp)).

Clay is used in products ranging from paper, paint, cosmetics, and pharmaceuticals to construction materials like bricks and cement. The absorbent and malleable properties of clay also make it ideal for ceramics and pottery. Understanding the geology of clay deposits allows mining companies and industries to locate and utilize this versatile mineral more efficiently.

This article will examine where significant clay deposits can be found around the world, how they form, and the mining and processing required to prepare the clay for commercial use.

Definition of Clay

Clay is a fine-grained natural soil material composed primarily of hydrated aluminum silicates, often containing variable amounts of iron, alkali metals, alkaline earths, and other cations (Encyclopedia Britannica). The clay minerals in soil develop plasticity, or the ability to be molded or shaped when wet, but can be hardened through drying or firing.

The key properties of clay include:

- Particle size smaller than 0.002 mm in diameter

- Plasticity – can be molded when wet

- Hardens when dried or fired

- Absorbs and holds moisture

- Adsorbs and holds positively charged ions (cations)

Clays are distinguished from other fine particles such as silt based on size, plasticity when wet, and the type of minerals present (Wikipedia). There are many varieties of clay based on mineralogical composition.

How Clay Forms

Clay minerals primarily form from the natural weathering and decomposition of feldspar rocks through hydrothermal and surface processes. The weathering of feldspar occurs over geologic timescales when rocks containing potassium feldspars come into contact with carbonic acid formed from rainwater and carbon dioxide in the atmosphere. This chemical weathering breaks down the crystalline structure of feldspar, releasing alumina and silica that combine with water to form clay minerals.

The feldspar weathering process begins when feldspar crystals are exposed to water. The water slightly dissolves the feldspar surface, allowing carbonic acid to penetrate the crystal structure. This acid then reacts with the potassium ions in the feldspar, forming potassium bicarbonate which dissolves into the water. As potassium ions are removed, the crystalline structure of the feldspar becomes unstable and begins to break down. The released silica and alumina molecules combine with water to form a gel-like substance. Over time, this gel crystallizes into layered sheet silicate clays like kaolinite and smectite.

In addition to chemical weathering, clays can form through hydrothermal processes. Hot aqueous solutions circulating through rock fractures leach out silica and alumina from feldspar. This hydrothermal leaching forms clay deposits in veins and fracture networks underground. Physical weathering processes like freezing, thawing, glaciation, and mechanical erosion also expose fresh feldspar surfaces to chemical weathering and transport clay particles to downstream sedimentary deposits.

Major Clay Deposits

Some of the largest and most significant clay deposits worldwide are located in the United States, Brazil, Ukraine, Germany, China, and the United Kingdom.

In the United States, the largest deposits are located in Georgia, Tennessee, Alabama, North Carolina, and South Carolina where kaolinite clay is mined from the coastal plain region. According to the USGS, the five leading kaolinite producing states account for more than 80% of total U.S. kaolin output (USGS).

Brazil contains abundant kaolin reserves located in the Amazonas state. According to a report, Brazil holds 12% of the global kaolin reserves and is the second largest clay exporter after the United States (Murray, 2006).

Ukraine holds enormous reserves of kaolinite and ball clays totaling 1.5 billion tons. The key deposits are located in the Dnipropetrovsk, Donetsk, Zhytomyr, Kharkiv, Cherkasy, Chernihiv and Kiev regions.

In Germany, major clay deposits are found in the Westerwald region which accounts for 90% of the ball clays mined in the country. Other deposits are located in the Thuringia and Saxony regions.

China has vast kaolinite resources estimated at more than 21 billion tons, located primarily in the Jiangxi, Guangdong, and Guangxi provinces. China is the leading global producer and exporter of kaolin products.

The two main china clay mining regions in the United Kingdom are in Cornwall and Devon. The area around St. Austell in Cornwall has been called the “China Clay Capital of the World” and produces around 1.2 million tons annually.

Clay in the United States

The United States is one of the top producers of clay in the world. According to the U.S. Geological Survey (USGS), the estimated value of clay production in the U.S. in 2021 was $1.5 billion. There are many major clay deposits located across the country.

Some of the most significant clay deposits are found in the southeastern states. The kaolin belt stretching through Georgia, South Carolina, North Carolina and Virginia contains huge reserves of kaolinite clay. Georgia alone accounts for over 20% of the total kaolin production in the U.S. Other major kaolin deposits are located in Florida, Oklahoma, Arkansas, Texas and Pennsylvania (Mineral Commodity Summaries 2022 – Clays, 2).

Bentonite clay is primarily mined in Wyoming, which produces 70-75% of all the bentonite in the country. Significant bentonite resources are also present in Texas, Mississippi, California, Arizona, Oregon and Colorado. The leading producers of ball clay include Tennessee, Kentucky, Texas and Indiana (Clays Statistics and Information | U.S. Geological Survey).

Other major clay producing states include Missouri, Ohio, Idaho, Alabama and Illinois. According to the USGS, in 2022 the top 5 mineral producing states by value were Nevada, Arizona, Alaska, Texas and California (Mapped: U.S. Mineral Production Value by State in 2022). Many of these states have substantial clay deposits that are actively mined.

Prospecting for Clay

Finding new deposits of clay starts with understanding the geology of an area. Geologists look for rock formations and soil types that are known to produce clay, such as shale or volcanic ash beds. Initial prospecting involves studying topographic maps and geological surveys to identify potential clay-bearing regions.

Once a promising area is identified, geologists conduct field surveys looking for visual signs of clay on the surface. They may dig test pits and shallow holes to extract samples for analysis. Laboratory tests determine the exact mineral composition, plasticity, firing qualities, and other properties of the clay. This helps evaluate whether the deposit is suitable for commercial uses.

Advanced technology like satellite imaging, aerial surveys, and geochemical analysis can also assist in detecting clay deposits. Seismic surveys can map underground clay beds. However, directly sampling and analyzing physical clay samples remains the most reliable prospecting method.

The size and quality of a clay deposit determines its economic value. High quality kaolin and bentonite clays have the highest commercial value. Large, easily accessible deposits near infrastructure for processing and transportation are most attractive for mining. The prospecting process aims to accurately delineate the extent, composition and properties of a clay deposit to evaluate its viability for commercial development.

Sources:

Mining Clay

Clay is typically mined from open pits using various equipment such as draglines, power shovels, front-end loaders, backhoes, and scrapers (AP-42, CH 11.25: Clay Processing). Open pit mining is an effective surface mining technique for extracting clay deposits over a large area and close to the surface.

For surface mining, the area is first cleared and pit outlines are established using surveying techniques. The overburden of rock and soil overlying the clay is removed and stockpiled separately. Power shovels or hydraulic excavators dig into the clay seam and load it into trucks for hauling to the processing plant. As mining advances, the pit is progressively deepened to access more of the clay deposit.

Where clay deposits are too deep for surface mining, underground mining methods may be used. Tunnels are driven into the deposit so that miners and equipment can extract the clay. Underground mining utilizes shafts and tunnels for access. Rooms or galleries are excavated from the main access ways using explosives, machines, or hand tools to break up the clay. The broken clay is then hauled above ground for processing (Clays).

Processing Clay

Clay in its natural raw form is not useful for commercial purposes. It contains impurities like sand, silt, organic matter, and minerals that must be removed. There are two main methods for processing raw clay to make it usable – the wet process and the dry process.

In the wet process, the raw clay is mixed with water to create a slurry which is pumped into settling ponds. The clay particles, being finer, remain suspended while the impurities like sand sink to the bottom. The top layer of clay slurry is then pumped out and dried. This can be achieved through filtration, evaporation, or pressing. The dried clay is then ground into a powder and screened to remove any remaining impurities. The wet process is more suitable for clays with high sand content.

The dry process involves crushing the raw clay with rollers and grinding it into a fine powder. The powder is then screened to remove impurities and mixed with 20-30% water to achieve a plastic consistency for shaping. The dry process is mostly used for higher grade kaolin clays. Once processed, the clay is bagged and sold for different applications.

Clay processing is vital to remove impurities and improve workability, strength, and other properties. Both wet and dry methods are aimed at yielding a pure clay powder suitable for pottery, ceramics, tiles, refractories, and other industrial uses.

Source: https://ancientpottery.how/how-to-process-clay/

Major Uses of Clay

Clay has a wide variety of uses and applications. Here is an overview of some of the main ways that clay is utilized:

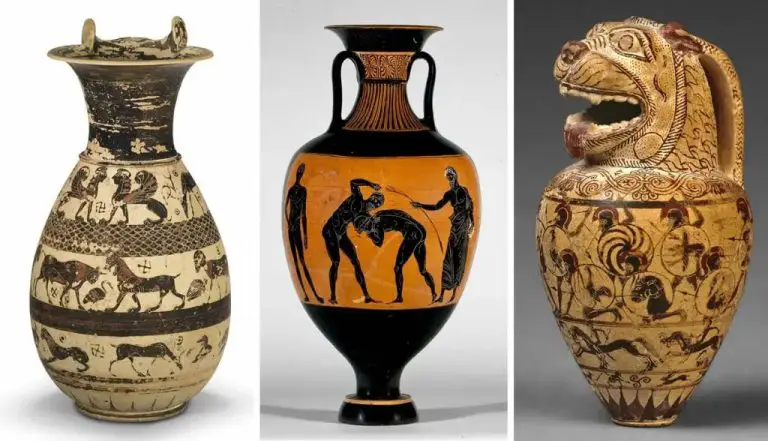

Pottery – One of the most well-known uses of clay is for making pottery items like vases, plates, bowls, and tiles. The clay is shaped while wet and then fired in a kiln to harden it.

Brick and tile – Clay bricks and roof tiles have been used in construction for thousands of years. Modern brick production involves extruding clay into the desired shape and then firing it.

Ceramics – Porcelain and bone china are types of ceramics made from clay. These are used to create artworks as well as tableware and decorative objects.

Paper – Clay is used as a coating and filler to create high quality glossy paper.

Cement – Clay is an important ingredient in Portland cement along with limestone, sand, and other materials.

Drilling – Bentonite clay is used as a drilling mud in oil and gas well drilling operations to lubricate the drill bit and transport drill cuttings.

Cosmetics – Clay masks and mud packs help cleanse and detoxify skin and are used in skin care routines. Fuller’s earth clay is commonly used for this.

Medicine – Kaolin clay is the active ingredient in medicines used to treat diarrhea and upset stomachs.

Waste Containment – Compacted clay and bentonite clay are used to line landfills and provide barriers in hazardous waste containment.

Clay is an exceptionally versatile material that lends itself to a diverse array of applications due to its unique physical and chemical properties.

Conclusion

In summary, clay is an abundant natural resource that has many uses, from pottery and construction to industrial applications. There are major clay deposits found across the world, including large deposits in the United States. Significant global clay deposits are located in regions like Brazil, India, China, and Germany among others. In the US, substantial clay deposits have been found in states such as Missouri, Ohio, California, and North Carolina. There are several types of clay with unique properties, formed through the weathering and decomposition of feldspar. While traditional clay prospecting involved analyzing soil samples, modern prospecting uses advanced geoscience techniques to identify potential clay deposits. Overall, clay is an incredibly versatile material found across the world, with major deposits that supply global industries.