Where Does Potters Clay Come From?

Potters clay, also known as ceramic clay or simply clay, refers to clay that is used to make pottery and ceramics. It is composed of fine particle soil that becomes pliable after water has been added and has been mixed thoroughly. According to Pottery Crafters, the most common ingredients in pottery clay are silica, alumina, and water.

Potters clay is available in natural and processed forms and ranges in color and properties. Potter’s clay originates from sediments in river beds or in deposits near streams that have been weathered down from parent rocks. Over time, these deposits accumulate and clay is formed from them through physical, chemical, and biological processes. Most commercial pottery clay undergoes mining and refining processes before being sold for use.

Types of Clay

The main types of natural clay deposits used in pottery and ceramics are kaolin, ball clay, and stoneware clay.[1]

Kaolin clay, also known as China clay, is white in color and has a fine particle size. It fires to a light color and is used to make porcelain. Kaolin clay has high plasticity and strength when dry.[1]

Ball clay is very plastic and has high shrinkage when fired. It fires to a light color and is used in whiteware ceramics and as a plasticizer in stoneware clays.[1]

Stoneware clays are plastic but have lower shrinkage and coarser particles than ball clay. They fire to various shades of brown and are commonly used for stoneware pottery.[1]

Clay Formation

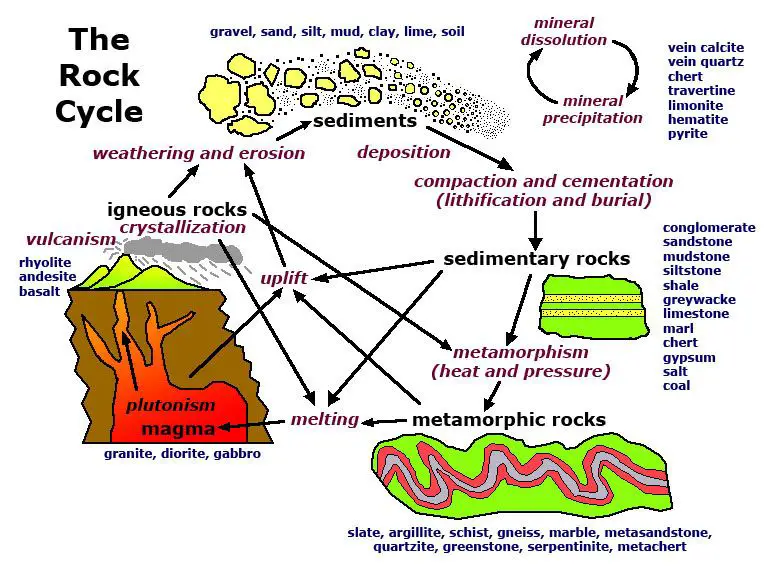

Clay deposits are formed over long periods of time through the weathering and erosion of existing rocks. As rocks break down due to exposure to water, air, changes in temperature, living organisms, and other environmental factors, the small clay particles are liberated from the parent rock. These clay particles are transported by water, wind, and ice to deposit in lakes, oceans, river beds, and low-lying areas.

The most common types of rock that create clay deposits include granite, feldspar, and volcanic ash or tuff. Feldspar in particular is abundant in the Earth’s crust and weathers into very fine clay particles. As these rocks slowly break down through weathering processes, the small clay particles are freed and transported away by erosion. Over time, the accumulation and deposition of these clay sediments leads to concentrated clay deposits.

Additionally, clays can form directly from the chemical weathering of volcanic ash or rocks underground. As hot, mineral-rich waters flow through cracks and spaces in rock, clay minerals precipitate out. These chemical sedimentary processes lead to clay deposits without requiring the transportation of eroded particles.

Overall, the formation of concentrated, mineable clay deposits occurs over thousands or millions of years as existing rocks gradually weather, erode, and transport fine clay particles to areas where they accumulate in purer deposits suitable for use in ceramics and other applications.

Sources:

https://pubs.usgs.gov/info/clays/

Clay Mining

Natural clay deposits are most often found through surface mining operations. Surface mining involves removing shallow topsoil and subsoil layers using heavy equipment like bulldozers, scrapers, and front-end loaders. The exposed clay deposits are then extracted using excavators or draglines. Surface mining techniques like open-pit mining allow high-volume production with lower costs compared to underground mining.

Underground mining is used when clay deposits are located too deep below the surface for surface mining. Underground mining involves sinking shafts to reach deeper deposits and using machinery like continuous miners, bolters, and haulage vehicles to extract the clay. Tunnels are created as mining advances and the extracted clay is brought to the surface through the shafts. Underground mining can better target the highest quality clay seams, but has higher operational costs.

According to the EPA’s AP-42 document on clay processing, most clay in the United States is extracted through surface mining methods using heavy equipment like draglines, power shovels, front-end loaders, backhoes, and scrapers. The particular technique used depends on factors like the clay’s location and quality.

Clay Refining

After clay is mined, it goes through a refining process to improve its properties and make it suitable for pottery and other uses. There are several steps involved in refining clay:

Crushing – Mined clay often contains rocks, roots, and other debris that need to be removed. The clay is put through a crusher to break it into smaller pieces and separate out larger contaminants.

Screening – The crushed clay is passed through a screen to filter out rocks, roots, and remaining debris. Screens with different sized mesh are used to produce clay particles of a uniform size.

Blending – Different types of clay are often blended together to achieve desired properties like workability, firing color, and strength. Blending homogenizes the clay batch and improves plasticity and cohesiveness.

Aging – Freshly mined clay contains a high moisture content that needs to be reduced. The clay is left to sit in open air for weeks or months to naturally age and lose moisture. This improves the clay’s stability and elasticity when working the material.

Slurry Mixing – Clay powder can be mixed with water to create a thin slurry, allowing fine particles to separate from gritty contaminants. The settled clay slurry is then dried and processed further.

Levigation – Slurried clay can also be passed through a series of settling tanks. The clay particles settle out based on size, separating fine clay from silt and sand particles. This levigation process refines the clay’s particle size distribution.

These refining steps purify the clay and prepare it for shaping into ceramics and pottery (Source). The methods remove debris, homogenize particle size, and improve plasticity and workability. Proper refining transforms raw clay into a usable material for crafting artisanal wares.

Geographic Sources

Clay is found and mined all over the world. Some of the largest sources of clay deposits include:

The United Kingdom: Large kaolin (white clay) deposits are found in Cornwall and Devon. Ball clay mining takes place in Devon and Dorset. Common clay extraction occurs across the UK.

United States: According to the US Geological Survey, the leading clay producing states are North Carolina, Georgia, California, Texas, Alabama, and Ohio. Deposits are found across the central and eastern US.

Germany: The Westerwald region contains major clay deposits that have been mined since Roman times. The clay is used for ceramics and bricks. Germany is a leading global producer of clay.

China: China contains vast clay deposits and is the world’s biggest producer of clay. Key mining areas include the provinces of Guangdong, Jiangxi, and Guangxi.

Other major producers include Brazil, India, Ukraine, Iran, Thailand, Mexico, Colombia, and Russia.

Sustainable Clay

Clay mining can have negative environmental impacts if not done sustainably. Irresponsible mining techniques can lead to land degradation, deforestation, and habitat destruction. However, some mining companies are adopting more sustainable practices. For example, in the Netherlands clay mining companies work to return the land to a natural state after mining is completed. The pits fill with water over time, creating new wetlands that support biodiversity.

According to the Ceramic Industry Association, “sustainable Dutch clay excavation [is] a renewable resource” (Cerameunie). Their video demonstrates how the Netherlands has implemented sustainable mining regulations, including remediating land after mining and excavating clay in phases. This allows new habitat to be created even while mining activities continue nearby.

Other sustainability practices include recycling water used during mining and processing, restoring topsoil after mining for future agricultural use, reducing energy consumption and emissions, and sourcing clay responsibly. With conscientious policies and innovation, clay can often be mined sustainably.

Synthetic Clay

Synthetic clay is an alternative to natural clay that is man-made in a laboratory setting. The main types of synthetic clay are polyester clay and polymer clay. Polyester clay is made from polyester resins and was developed to be a substitute for natural modeling clay. Polymer clay is made from plastic polymers like polyvinyl chloride (PVC) and is popular for arts and crafts applications.

Synthetic clays have some advantages compared to natural clay. They are generally cleaner and easier to use since they do not dry out. Synthetic clays also tend to be more durable and smoother than natural clay. However, synthetic clays often do not replicate the texture and organic feel of natural clays. They also lack the mineral content that provides the absorbent cleaning properties of natural clay. While synthetic clays have their uses, natural clay remains preferable for many traditional clay applications.

According to Griot’s Garage (https://www.griotsgarage.com/brilliant-finish-synthetic-clay/), synthetic clay can provide faster removal of contaminants, improved durability, and can clean more cars than natural clay bars. However, enthusiasts on forums like Reddit often prefer the feel and cleaning power of natural clay bars over synthetic options (https://www.reddit.com/r/AutoDetailing/comments/ag8n4i/griots_synthetic_clay_vs_clay_bar/).

Clay Grades

Clays are graded based on properties like plasticity, particle size distribution, and firing characteristics. Some common grading systems include:

The Unified Soil Classification System (USCS) grades clays into categories like lean clay, fat clay, and organic clay based on the percentage of clay-sized particles (<0.002 mm) and plasticity characteristics measured by the liquid limit and plasticity index. Lean clays have lower plasticity, while fat clays are highly plastic. Organic clays contain organic matter. The USCS is widely used in geotechnical engineering (Unified Soil Classification System).

Some art clay manufacturers use grading scales with numbered categories indicating firing temperature ranges and levels of plasticity or clay hardness. For example, a clay graded as a “number 4 clay” may indicate a mid-range firing temperature of 2,000-2,300°F and moderate-to-high plasticity (CHS GRADING POLICY/SCALE).

Conclusion

Clay is an essential natural material that has been used by humans for thousands of years for pottery, sculpture, and construction. The diverse types of clay come from specific geological formations and locations around the world. Understanding the sources and properties of clay provides critical insight into this versatile material.

The key takeaways are that clay forms from the weathering and decomposition of feldspar rock, the different types have their own characteristics based on mineral content and firing temperatures, and clay deposits are mined from certain regions globally. While natural clay is still predominantly used, some synthetic clays are also produced.

Knowing the origins and qualities of potters’ clay enables proper selection for intended usage. As with any natural material, sustainable and ethical sourcing practices are important for clay procurement. With informed understanding of clay sources and responsible mining, this incredible substance will continue serving artists, craftspeople and industries worldwide.