Which Brick Is Best For Fire?

Selecting the right type of brick is crucial for any high-heat application such as fireplaces, ovens, furnaces, and chimneys. The brick’s ability to withstand intense heat without cracking or deteriorating is referred to as its fire rating. Choosing a brick with the proper fire rating helps ensure the safety and longevity of fire-based structures. Bricks with insufficient fire resistance can crack or explode when exposed to heat, leading to damages or injuries. Different classifications of brick have varying levels of heat tolerance, based on their composition and manufacturing method. Understanding the factors that determine a brick’s fire performance helps builders choose the optimal product for fire safety.

Fire Ratings

The fire rating system for bricks is based on European standards EN 13501-1, which classifies building materials based on how they react and resist fire (Vandersanden, 2023). Bricks are classified as A1, meaning they are non-combustible and do not contribute to fire growth at all.

Bricks can withstand fire for extended periods of time depending on their properties. Testing by Underwriters Laboratories found that a typical clay brick wall with Type S mortar could withstand fire for over 4 hours before reaching critical temperature limits (Brick Industry Association, 2022). The length of fire resistance depends on brick density, wall thickness, and other design factors.

The required fire rating tends to be higher for commercial than residential buildings. Commercial spaces like offices, schools, and hospitals often need at least 1-hour fire rated exterior walls. Residential homes only require fire rated walls between units, with exterior walls having no rating unless part of the fire separation distance rules (Interstate Brick, 2021). Overall, choosing bricks with an A1 rating provides excellent inherent fire resistance for both building types.

Brick Materials

The most common brick materials include clay, concrete, and calcium silicate. Clay bricks are one of the most popular and widely used brick types due to their durability, availability, and cost-effectiveness (Fire Resistance of Brick Masonry). They are made from clay that is shaped and fired at high temperatures. Concrete bricks are made from a mixture of cement, sand, water and aggregate material. They have high compressive strength and are more resistant to moisture compared to clay bricks. Calcium silicate bricks are made from sand, lime and silica. They have excellent resistance to high temperatures and thermal shock.

In terms of flammability and heat resistance, calcium silicate bricks are considered the most fire-resistant with the ability to withstand temperatures exceeding 1000°C without damage. Clay bricks typically have fire ratings around 1200°C. Concrete bricks also have good heat resistance but may spall, crack or explode when exposed to extreme heat. Overall, traditional brick materials like clay and concrete provide excellent protection against the spread of fire when used properly in wall construction.

Brick Density

The density of a brick is directly related to its fire resistance rating. Denser bricks contain less air pockets and are more resistant to heat transfer, allowing them to withstand fire exposure for longer periods of time before failing.

According to the Brick Industry Association, the density of typical bricks ranges from 120-135 pounds per cubic foot. Heavier high density bricks range from 140-165 pounds per cubic foot, while lighter low density bricks are 90-115 pounds per cubic foot [1]. The denser the brick, the higher its fire rating.

For example, a standard 2-hour fire rated wall assembly requires high density bricks with a minimum density of 130 pounds per cubic foot at a thickness of 3.8 inches. A 4-hour fire rated wall, on the other hand, needs extra dense firebrick at 165 pounds per cubic foot and a thickness of 5.75 inches [2].

Brick Thickness

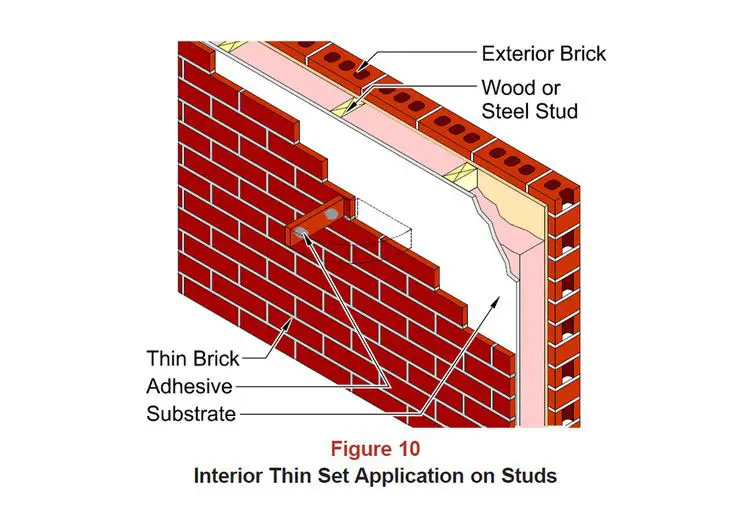

The thickness of a brick wall plays a key role in determining its fire resistance rating. Thicker bricks provide increased fire protection by creating a more substantial barrier to heat transfer. According to the Brick Industry Association, the equivalent thickness method allows the fire resistance rating of a brick wall assembly to be determined based on the total cross-section thickness of the masonry and surface finishes such as plaster or mortar [1].

Typical thicknesses for fire-rated clay brick walls are:

- 4-inch brick – Provides 1 hour fire resistance

- 6-inch brick – Provides 2 hours fire resistance

- 8-inch brick – Provides 3 hours fire resistance

- 12-inch brick – Provides 4 hours fire resistance

According to the Western States Clay Products Association, adhered brick veneer of 1 3/4″ combined thickness provides 1 hour of fire resistance, while 2″ of adhered veneer provides nearly 2 hours [2]. Thicker brick walls slow the transmission of heat, helping protect building occupants and giving more time for safe evacuation.

Surface Finishes

A brick’s surface finish can greatly impact its fire resistance. Glazed bricks, which have a glossy ceramic coating, tend to have higher fire resistance than unglazed bricks. According to Glen-Gery, a leading brick manufacturer, glazed brick can achieve fire ratings over 2 hours, compared to 1 hour for unglazed brick (https://glengery.com/sites/default/files/2019-10/Glazed_Brick_Product_Profile_1.19.pdf).

The ceramic glaze creates an impermeable surface that prevents flames, heat, and gases from penetrating the brick. It also resists cracking and spalling when exposed to high temperatures. Uncoated brick is more porous and prone to surface erosion during a fire. The glaze’s low thermal conductivity also keeps the inner brick insulated. This allows glazed brick to better maintain its structural integrity when exposed to extreme heat.

Overall, glazed brick’s dense, ceramic coating improves multiple aspects of fire performance. This makes it a top choice when fire resistance is a priority.

Firebrick

Firebrick, also known as refractory brick, is a block-shaped brick made from refractory ceramics that withstand extremely high temperatures. According to the Medium article “What Are Properties and Applications of High Temperature Fire Brick”, firebricks have an apparent porosity below 45% and can withstand high temperatures between 1580–1760°C. Common materials used to manufacture firebrick include fire clay, silica, magnesite, and chamotte.

Firebricks have many applications where high temperature resistance is required, such as:

- Lining kilns, furnaces, fireboxes, and fireplaces – Firebricks line high heat areas and insulate brick or metal structures from extreme temperatures during processes like metal smelting and glassmaking according to Wikipedia’s “Fire brick” article.

- Heat containment – The interior of wood burning stoves, boiler systems, and industrial incinerators rely on firebricks to retain heat according to the Ceramic Fiber Corporation.

- Insulation – Firebricks have low thermal conductivity making them effective insulation. The space shuttle tiles were made of firebrick material.

Properties like high density, load bearing strength, and thermal shock resistance allow firebricks to withstand the demanding conditions present during high heat applications according to the sources.

Testing Standards

There are two main ASTM (American Society for Testing and Materials) standards for testing fire bricks:

ASTM E119 – Standard Test Methods for Fire Tests of Building Construction and Materials[1]

This test method exposes test specimens to a standard fire exposure that follows a specified time-temperature curve. It evaluates fire resistance for walls, floors, roofs, beams, and columns. The test measures transmission of heat through the specimen, fire integrity (flame spread), and structural integrity (collapse).

ASTM C1261 – Standard Specification for Firebox Brick for Residential Fireplaces[2]

This test evaluates the physical properties of fire bricks, like density, thermal conductivity, compressive strength, and more. It helps ensure fire bricks can withstand the high temperatures inside residential fireplaces over time.

These standard tests help validate the performance capabilities of different fire bricks when exposed to high heat and flames. They provide manufacturers, builders, and consumers with quality benchmarks.

Cost Comparison

Firebricks are more expensive than common brick types like red bricks or concrete bricks due to their specialized properties. On average, standard bricks cost around $0.50-$1 per brick, while fire bricks tend to start around $3 per brick.

Higher fire resistance ratings directly correlate with higher costs. For example, a basic unfired clay brick may provide minimal fire resistance at a low cost. Moving up to a fired clay brick increases costs but provides Type FBX fire resistance. Finally, high density firebricks designed for extreme heat offer Type A fire resistance but can cost over 10 times more than a basic unfired brick.

There are ways to balance fire protection and budget. Using higher-rated fire bricks on the interior layers most exposed to heat, while using cheaper standard bricks on the outer layers can provide adequate fire resistance at a reasonable overall cost.

Conclusions

The different types of bricks have varying levels of fire resistance, depending on their density, thickness and surface finishes. Firebrick and high density bricks perform the best in high heat fire applications. Firebrick is made specifically for fireplaces and kilns, with a high alumina content that can withstand temperatures up to 2000°F. High density common bricks with a smooth face are the next best option, rated for temperatures up to 1000°F.

Pumice and low density bricks should be avoided for fire applications, as they have lower heat resistance. Insulating firebrick is designed to retain heat and is not suitable as a fire brick in direct contact with flames. Surface finishes and coatings also play a role, with smooth faces superior to textured or frogged surfaces.

When choosing the best fire brick, opt for firebrick first, followed by a high density common brick with a smooth face and uniform shape. Check the manufacturer’s stated fire rating and ensure the brick is at least 2.5″ thick. While firebrick is more expensive, it will last longer than common brick when exposed to repeated fire. Investing in quality firebrick suited for high temperatures will provide better performance and require less frequent replacement.