Which Wire Is Positive On A Type K Thermocouple?

A thermocouple is a sensor used to measure temperature. It consists of two dissimilar metal wires joined together at one end. This junction of two metals produces a small voltage that is dependent on temperature. This voltage is called the thermoelectric effect or Seebeck effect, named after Thomas Johann Seebeck, who accidentally discovered the phenomenon in 1821.

Thermocouples work due to the Seebeck effect – when two dissimilar metals are joined, a voltage is produced proportional to the temperature difference between the junction and the free ends. The voltage signal produced can be measured and interpreted to determine the temperature. Thermocouples rely only on this phenomenon and do not require an external power source.

Thermocouples are a popular temperature sensor due to being inexpensive, interchangeable, have a wide temperature range and can measure a wide range of temperatures. They are used in many industrial processes to monitor temperature for control and safety. Common applications include chemical production, food processing, power generation, automotive, HVAC systems and more.

Types of Thermocouples

Thermocouples are available in different combinations of metals or calibrations, each suited for measuring a different range of temperatures. The most common types of thermocouples are:

Type J – Made of iron and constantan, type J thermocouples are one of the most common general purpose thermocouples with a temperature range of -210 to 1200°C (-346 to 2192°F). They have high accuracy and sensitivity over a wide temperature span. Type J thermocouples are inexpensive and compatible with various thermocouple connectors.

Type K – Comprised of chromel and alumel, type K thermocouples can measure temperatures ranging from -270 to 1372°C (-454 to 2501°F). They have the widest temperature range of the base metal thermocouples. Type K thermocouples offer high stability and resist oxidation at high temperatures.

Type T – Made from copper and constantan, type T thermocouples have a temperature range of -270 to 400°C (-454 to 752°F). They have high accuracy and provide stable measurement in cryogenic environments down to absolute zero. Type T thermocouples are commonly used as refrigerator thermometers and for low temperature measurements.

Type E – Constructed from chromel and constantan metals, type E thermocouples measure temperatures from -270 to 1000°C (-454 to 1832°F). They have high output for the small temperature range which provides good resolution. Type E thermocouples are compatible with high temperature oxidation and reducing environments.

Other types like B, R, S and N also have specific temperature ranges, sensitivities, and applications suited for particular purposes. The wide range of thermocouple types allows temperature measurement in diverse environments and conditions.

Type K Thermocouples

Type K thermocouples are one of the most commonly used types of thermocouples. They are composed of chromel (90% nickel, 10% chromium) and alumel (95% nickel, 2% manganese, 2% aluminium, 1% silicon) conductors. Type K thermocouples have a temperature range of -200°C to +1200°C (-328°F to +2192°F) making them versatile for many industries and applications.

Some key properties of Type K thermocouples include:

- Wide temperature range

- Inexpensive compared to other thermocouple types

- Fairly rugged construction

- Good oxidation resistance in many environments

Type K thermocouples are used in a variety of industries including chemical processing, HVAC, food processing, petrochemical, and power generation. Common applications include gas turbine monitoring, plastic molding, bearings and motors, diesel engines, and laboratory measurements.

Overall, Type K thermocouples provide a versatile temperature measurement solution due to their wide range, low cost, and robustness. Their properties make them one of the most widely used thermocouple types across many industries.

Thermocouple Wiring

Thermocouples work based on the thermoelectric effect, which causes a voltage to be generated when two dissimilar metals are joined together and a temperature gradient is applied across the junction. This voltage can be measured and correlated back to determine the temperature.

The two wires that make up a thermocouple are called the thermocouple extension wires. They are made up of specific thermoelement alloys matched to the type of thermocouple (e.g. Chromel and Alumel for Type K). The wires are joined together at one end to form the hot junction, which is placed at the point of measurement. The other end of the wires connect to the measuring instrument and form the cold junction. The temperature difference between the hot and cold junctions produces the thermal EMF that is measured.

The extension wires allow the thermocouple to connect back to the instrument for measurement while the hot junction is placed in the process environment. Standard thermocouple extension wire is made to match the correct alloys for each type of thermocouple to maintain the integrity of the circuit (Omega). Proper wiring with the right polarity is critical for accurate temperature measurement.

Thermocouple Polarity

Thermocouples rely on the Seebeck effect to generate a voltage based on a temperature difference between two dissimilar metals. This means the two wires in a thermocouple are made of different metals or alloys. One wire will act as the positive electrode and one as the negative electrode, creating a simple electrical circuit.

By convention, the red wire is typically used for the negative side and the other color wire, often yellow, is used for the positive side. The polarity needs to be maintained for the thermocouple to work properly. If the two wires are reversed, the measured temperature will be incorrect.

The convention of red for negative and yellow for positive applies specifically to Type K thermocouples, the most common type. Other thermocouple types may use different color coding (source).

Polarity matters because the Seebeck voltage produced is dependent on the two dissimilar metals. Reversing the polarity would result in the voltage being generated in the opposite direction, leading to an incorrect temperature reading.(source)

Identifying Type K Polarity

There are a few methods for identifying the polarity of a Type K thermocouple based on the colored insulation and labeling standards:

The positive wire on a Type K thermocouple will typically have yellow insulation. The negative wire is insulated in red. This color coding follows the ANSI/ASTM E230 standard for Type K thermocouples used in the United States (Source).

The insulation may also be imprinted or labeled ‘+’ and ‘-‘ to denote polarity. Positive is almost always yellow, and negative red, regardless of imprints (Source).

You can use a magnet to test polarity. The negative wire will be slightly more attracted to the magnet than the positive. This is because the negative Type K wire contains more magnetic nickel (Source).

An ohmmeter or multimeter can also determine polarity by measuring the resistance. The positive wire will show more resistance than the negative (Source).

Positive Wire on Type K

Type K thermocouples consist of two wires made from different metals or alloys that are welded together at one end. The difference in voltage between the two wires is measured to determine temperature. One wire is designated as positive and the other as negative. For a Type K thermocouple, the positive wire is yellow, while the negative wire is red [1].

The yellow wire is made of nickel-chromium alloy, while the red wire is made of nickel-aluminum alloy. When these two dissimilar metals come into contact, a voltage is generated proportional to temperature. The yellow nickel-chromium wire becomes more positively charged relative to the red nickel-aluminum wire as temperature increases [2]. Thus, the yellow wire is designated as positive.

Properly identifying polarity is critical for accurate temperature measurements. Connecting the thermocouple wires incorrectly will result in reversed polarity and large errors. Remembering that yellow is positive makes it easy to wire a type K thermocouple correctly.

Wiring Considerations

When wiring thermocouples, it is critical to follow proper polarity and avoid shorts or mismatches. The two wires that make up a thermocouple are referred to as the hot and reference junction. The positive wire will depend on the thermocouple type being used. For Type K thermocouples, the positive wire is colored yellow in the U.S. and European coding systems.

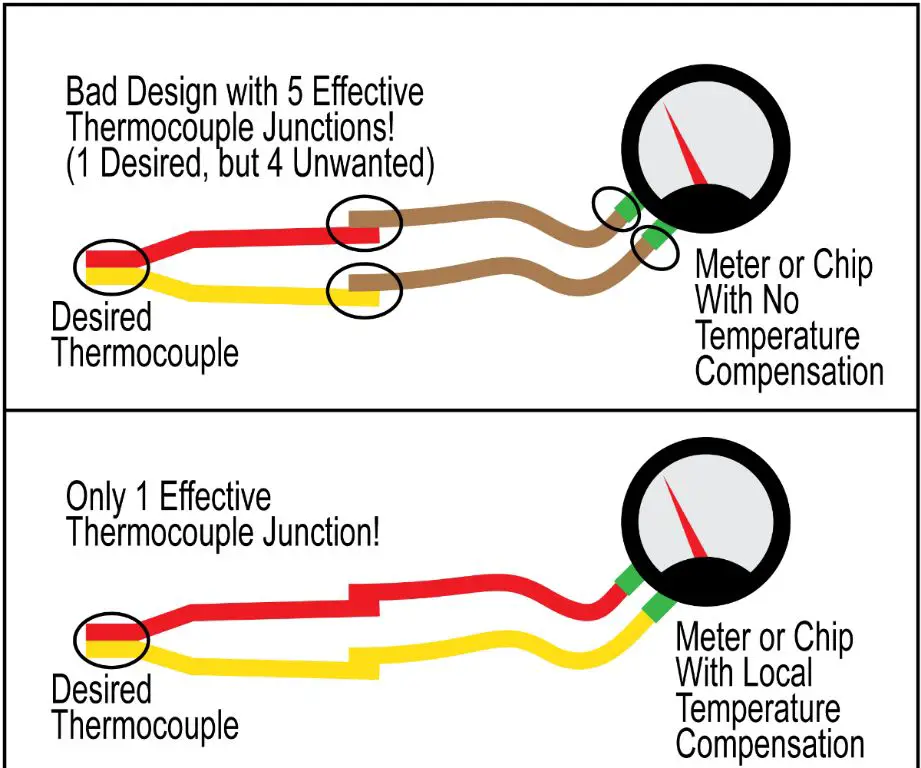

To maintain proper polarity, extension wires must be made of the same alloys as the thermocouple wires. Mismatched metals can create a new thermocouple junction, causing inaccurate readings. It is also important to avoid electrically shorting the thermocouple wires together or to ground, as this will interfere with voltage output and temperature measurement.

Proper wiring techniques should be used, including using twisted pair or shielded cables for extending or connecting the thermocouple to avoid electromagnetic interference. Connectors and terminals should also match the thermocouple wire metal types. Following basic wiring best practices helps ensure accurate, noise-free temperature measurements.

Applications

Type K thermocouples are commonly used in a wide variety of applications that require accurate temperature measurement, especially in higher temperature environments up to 1260°C. Some examples of using Type K thermocouples include:

Industrial processes – Type K thermocouples are often used to monitor and control temperatures in industrial furnaces, boilers, kilns, and other high-temperature equipment. Proper wiring polarity is critical for accurate control.[1]

Food processing – Type K thermocouples can monitor temperatures during baking, frying, sterilization, pasteurization and other food preparation processes. Maintaining the correct polarity allows precise temperature regulation.[2]

HVAC systems – Type K thermocouples with proper polarity wiring are used to measure air and gas temperatures in heating, ventilation and air conditioning systems.

Automotive – Type K thermocouples are used to measure exhaust gas temperatures in automotive engines and catalytic converters. Proper wiring helps ensure emissions stay within required limits.

In these and other applications, following polarity conventions and wiring the positive thermocouple wire correctly is essential for accurate temperature measurements and control.

[1] https://www.thermometricscorp.com/thertypk.html

[2] https://www.omega.com/en-us/resources/thermocouples-applications

Conclusion

In summary, for Type K thermocouples, the positive wire is yellow and the negative wire is red. The yellow wire is made of Chromel while the red wire is made of Alumel. According to the ANSI standard, Chromel (positive) is always yellow and Alumel (negative) is always red for Type K thermocouples. This consistent color coding allows for proper polarity and eliminates errors when wiring Type K thermocouples in various applications. Knowing which wire is positive on a Type K thermocouple is essential for accurate temperature measurement and control.