Do You Make Or Do Pottery?

Pottery, also called ceramics, refers to objects made from clay that have been shaped and then hardened through processes such as drying or firing. The term pottery encompasses a wide range of ceramic wares including earthenware, stoneware, and porcelain. Pottery is one of the oldest human inventions, dating back to prehistoric times, and ceramic objects have been fashioned to serve both practical and artistic ends throughout history.

According to the Merriam-Webster dictionary, pottery can be defined as “ware (such as vases, pots, bowls, or plates) shaped from moist clay and hardened by heat.”1 The ASTM International defines pottery as “all fired ceramic wares that contain clay when formed, except technical, structural, and refractory products.”2 In essence, pottery refers to clay objects that have been permanently hardened through firing in a kiln.

The term “ceramics” is sometimes used interchangeably with pottery. Ceramics refers more broadly to objects made from nonmetallic minerals that have been permanently hardened by firing at high temperatures. So pottery is a type of ceramic, referring specifically to clay-based objects.

History of Pottery

The origins of pottery date back thousands of years. Archaeological evidence indicates that pottery was independently invented in various parts of the world, including China, Japan, Africa, and South America. According to the Art of Abys, the earliest known evidence of pottery dates back over 24,000 years ago to China, where simple clay figurines and vessels were discovered in the Xianrendong Cave. China has a particularly long history of pottery-making, with some of the earliest examples dating back to the Neolithic period over 10,000 years ago, according to Sifounios Pottery.

In the Near East, pottery was in use by 6000 BCE. According to the Tennessee Department of Environment and Conservation’s report “A Survey of Historic Pottery Making,” pottery artifacts recovered from Jōmon sites in Japan date back as far as 10,500 BCE. In South America, pottery has been found dating to 4000 BCE along the coast of Ecuador.

Early pottery was often simple hand-built and undecorated functional vessels. As pottery techniques developed over thousands of years, decorative techniques emerged across cultures. Archaeological discoveries continue to provide insights into the origins and evolution of this ancient craft around the world.

Types of Pottery

Pottery can be categorized into three main types based on the clay composition and the temperature at which it is fired: earthenware, stoneware, and porcelain.

Earthenware is made from clay that contains high levels of iron and other minerals. It is fired at lower temperatures, typically between 1,800-2,000°F. Earthenware is porous and opaque. It can be left natural or glazed to create a colored surface. Because of its porosity, earthenware absorbs liquids and is not suitable for holding water. It is weaker than stoneware and porcelain (Types Of Pottery Material – Knowledge Description And … – Jinn).

Stoneware contains fewer impurities than earthenware and is fired at higher temperatures between 2,200-2,400°F. It is less porous than earthenware, so liquids are absorbed at a slower rate. The higher firing temperature makes stoneware stronger and more durable. It has an opaque, non-reflective surface and can remain unglazed or be given colored glazes. Typical items made from stoneware include ovenware and crockery (Ceramic Material).

Porcelain is the most refined clay containing kaolin and feldspar minerals. It is fired at very high temperatures between 2,200-2,500°F. Porcelain is non-porous, hard, translucent, and has a white color, making it ideal for decorative items. The high firing gives porcelain a smooth glass-like surface. It can also be decorated with colored glazes. Porcelain is delicate and brittle compared to other types of ceramics (The Best and Worst Pottery Materials For Your Kitchen).

Pottery Techniques

There are several key techniques used in pottery making. The three main methods are:

Handbuilding involves shaping pottery by hand without the use of a potter’s wheel. Some common handbuilding techniques include pinch pots, coil building, and slab construction. Handbuilding allows artists to create unique asymmetrical forms not possible on the wheel. It provides great creative flexibility but requires practice to master (Source).

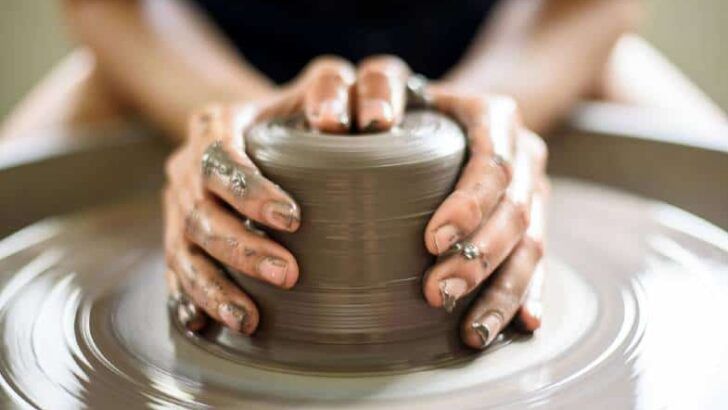

Wheel throwing is the process of using a potter’s wheel to shape clay into symmetrical ceramic forms. It involves centering the clay on the wheel and opening it up with controlled movements. Wheel throwing enables consistency and allows potters to make multiples of one design quickly and efficiently. However, it requires coordination and skill to center the clay and control the movements (Source).

Molding allows for production of multiple identical pieces. The clay is pressed into plaster molds that have been cast from an original modeled form. The clay takes on the inverse shape of the mold as it dries. While limiting creativity, molding enables consistency and is often used commercially. Source.

Decorating and Glazing

There are several techniques used for decorating and glazing pottery to add color, texture, and design. Two common methods are using slip and engobe. Slip is a liquid clay mixture that can be used to coat pottery pieces before firing. It comes in various colors and allows adding layers of color. Engobe is a similar slip coating but contains minerals like quartz or feldspar to create different effects. Engobes provide opaque colors compared to more translucent slips.

Another decorative technique is sgraffito where surface layers are scratched or etched to reveal the clay color underneath. This is done on leather-hard pots before bisque firing. Glazing is the final layer applied before the glaze firing. Glazes come in endless colors and textures like glossy, matte, or crackled. Glazes can be brushed, dipped, or poured onto bisqueware pieces. Decorating and glazing allow endless creativity in pottery design.

Sources:

Firing Pottery

Firing is one of the most important steps in creating pottery. It is the process of exposing clay objects to high temperatures in a kiln, which causes permanent physical and chemical changes that turn the clay into ceramic material. There are several methods for firing pottery:

Kilns

Most pottery is fired using an electric or gas kiln which can reach temperatures of over 1300°F. Kilns allow for precise control over temperature, atmosphere, and length of firing. There are various types of kilns used in ceramic firing including top-loading kilns, front-loading kilns, and computerized kilns. Kiln firing results in smooth, uniform, and predictable effects on the clay.

Pit Firing

Pit firing involves placing pottery in a fire pit or trench dug into the ground. Combustible material like sawdust, wood, leaves, or newspaper is layered over the pottery and set on fire. This more primitive firing technique results in less control and more uneven effects. According to the Ceramic Arts Network, pit firing can create beautiful flashes of color and patterning from ash deposits and uneven temperatures [1].

Raku Firing

Raku is a type of low-temperature pottery firing, usually done outdoors between 1475–1850°F. The pottery is removed from the kiln while red hot and placed into containers with combustible materials to create dramatic effects from the smoke. Raku firings create unpredictable patterns and colors. It was originally inspired by 16th century Japanese tea ceremony pottery according to The Pottery Wheel [2].

Contemporary Pottery

Contemporary pottery encompasses both art pottery and production pottery made in the present day. While some contemporary potters follow long-held traditions, others are branching out into new forms, styles, and techniques.[1]

Major contemporary art potters include Peter Voulkos, who pushed the boundaries of traditional pottery and helped establish the Abstract Expressionist Ceramic Movement.[2] Other influential artists are Ruth Duckworth, known for her innovative porcelain sculpture, and Jun Kaneko, recognized for large-scale sculptural forms.

On the production pottery side, there has been renewed interest in handmade functional ware, lead by potters like Shoji Hamada. Studio potters today make a wide array of functional pots, integrating both traditional and modern sensibilities. Overall, contemporary ceramic artists continue to find new means of expression, reflecting changing perspectives in the age of globalization.

[1] https://www.millicentrogers.org/collections/contemporary-pottery/contemporary

[2] https://thesun.my/buzz/contemporary-trail-glazers-GF10403500

Pottery as a Profession

Becoming a professional potter requires dedication, skill, and smart business practices. Many aspiring potters start by pursuing formal education in ceramic arts. There are certificate programs, associates degrees, and four-year degrees available at colleges, universities, and art schools focused on pottery and ceramics.

Hands-on apprenticeships are another excellent way to gain experience and learn from established potters. Working in a professional studio provides invaluable insights into the realities of making a living through pottery. Aspiring potters can reach out to studios directly to inquire about apprenticeship opportunities.

Running your own professional pottery studio is the dream for many potters. This requires business knowledge and a smart plan. Potters must find the right balance between creative expression and producing pottery that sells. Marketing, social media presence, and participating in art shows and craft fairs are essential. Success comes from loving the craft but also treating pottery as a business.

Pottery as a Hobby

For many people, pottery is a relaxing and creative hobby. There are several ways to get started with pottery as a hobby at home. The most essential equipment is a pottery wheel and a kiln, though beginners can start with handbuilding techniques that just require clay, basic tools, and minimal equipment.

Purchasing a pottery wheel and kiln new can be an expensive investment, with pottery wheels starting around $300 and kilns starting around $500 for a small hobbyist model. However, good quality used equipment can often be found at a more affordable price. Local pottery studios may also rent studio space with wheel and kiln access for hobbyists.

Another option to get started is by taking pottery classes at a nearby studio. Introductory classes cover topics like wheel throwing and hand building techniques. Classes provide access to studio equipment and allow beginners to gain skills under the guidance of an instructor without purchasing their own equipment. Prices for classes range from $100-$300 for a 6-10 week session.

For hobbyists with space and a budget to invest in their own equipment, starting pottery at home can be very rewarding. Beginners should start with an easy clay like stoneware or earthenware. Basic tools like ribs, trimming tools, cutting wires, and modeling tools can be purchased affordably. Having the right setup makes it convenient to work on projects as a creative outlet.

While starting up requires an investment, continuing costs can be modest for hobby pottery done at home. As long as hobbyists take care of their equipment and tools, they can last for years of enjoyment.

Conclusion

In summary, pottery has a long and rich history spanning thousands of years across many cultures. From basic functional wares to elaborate artistic pieces, humans have shaped, decorated, and fired clay to meet needs and express creativity. While pottery was once crucial for food storage and preparations, it evolved into an artform and craft appreciated for its beauty. Master potters developed ingenious techniques like the potter’s wheel and complex glazing methods to make pottery more refined. Today, pottery persists both as a profession and beloved hobby, with modern innovations helping potters create intricate works of art. Looking ahead, pottery will likely continue finding eager practitioners and audiences who value handmade, unique ceramics. Though materials and tools evolve, the human compulsion to mold form from formless clay endures, ensuring pottery’s legacy will live on for generations to come.