Clay Pottery Firing Techniques: Understanding The Process

Firing is the most critical step in creating durable pottery. It is the process of exposing clay wares to high temperatures in a kiln to cause permanent physical and chemical changes. Firing transforms soft, fragile clay into a strong, non-porous material by bonding the clay particles together through sintering. Sintering refers to the fusion of clay particles at temperatures typically between 1,800°F to 2,300°F.

The firing process hardens both the clay body and any ceramic glazes applied to create the final pottery. Vitrification occurs during firing as silica and fluxes melt, filling any pores in the clay. The end result is pottery with increased strength, rigidity, and impermeability.

Firing clay successfully requires carefully controlling temperatures and firing schedules inside the kiln. Mastering the firing process enables potters to consistently produce high quality ware with their desired characteristics. While unfired pottery is unstable and water-soluble, proper firing provides durability and transforms clay into a permanent finished product.

Understanding the physical and chemical changes during firing allows greater control over the final properties, colors, and effects achieved. With knowledge of critical firing principles, potters can troubleshoot any issues and continue perfecting their craft.[1]

Preparing the Kiln and Ware

Proper preparation of the kiln and ware is crucial for achieving a successful firing. The kiln must be thoroughly cleaned between firings to remove any dust, debris, or residual clay material. According to ceramicartsnetwork.org, all shelves, props, posts, and the kiln floor should be wiped down with a damp sponge to eliminate contaminants.

Pyrometric cones, which measure the heatwork and indicate when the firing is complete, must also be inspected prior to loading. Cracked or chipped cones should be discarded and replaced with new ones. The cones need to be stored in a dry environment to prevent pre-firing. Carefully place the pyrometric cones on the kiln shelf where they can be viewed through the peepholes during firing.

The greenware, bisqueware, or glazeware must be fully dry before loading into the kiln. Even small amounts of moisture can cause cracking or explosions from rapid steam expansion. Items should sit for sufficient time after cleaning or glazing to ensure bone-dryness. The ware should also be free of adhered bits of clay, glaze drips, or dusty surfaces which can prevent proper firing.

Loading the Kiln

When loading a kiln for firing pottery, it’s important to carefully stack and space the pots to allow for proper air circulation. Pyrometric cones, which measure the heatwork during firing, must also be placed in strategic locations throughout the kiln.

Pots should be spaced about 1-2 inches apart on the shelves to allow heat to fully circulate around each piece. Stacking them too close together can lead to underfired spots. Be sure to leave at least 1 inch between pots and the interior kiln walls as well. The spacing allows heat to reach all surfaces of the ware evenly.

Pyrometric cones are placed on kiln shelves alongside the pottery pieces. Cones bend and melt at specific temperatures, acting as visual indicators of when the desired heatwork is reached. It’s recommended to place cones at the top, middle, and bottom of the kiln to monitor conditions throughout. This helps ensure the firing is complete and even from top to bottom before the kiln is shut off.

Proper loading techniques like spacing pots apart and using pyrometric cones leads to beautifully fired results. Paying close attention to these details is what separates quality work from disappointing firings.

Popular Kiln Firing Methods

There are several popular methods for firing clay pottery in a kiln, each producing unique effects in the finished ceramic ware.

Biscuit Firing

Biscuit firing, also called bisque firing, is done at a lower temperature, usually around cone 08-04. This initial firing process hardens the clay body and makes the ware safe to handle and porous enough for glazing. Bisque ware is unglazed and the color is often a light bone color. Biscuit firing is done before applying glaze and then firing again at a higher temperature.

Single Firing

In single firing, the clay pottery goes through only one firing process with the glaze applied. The ware is loaded into the kiln and fired to a higher temperature, usually between cone 5-10 depending on the clay body and glaze ingredients. Single firing can achieve unique effects in the glaze as materials interact and melt together in one heating.

Reduction Firing

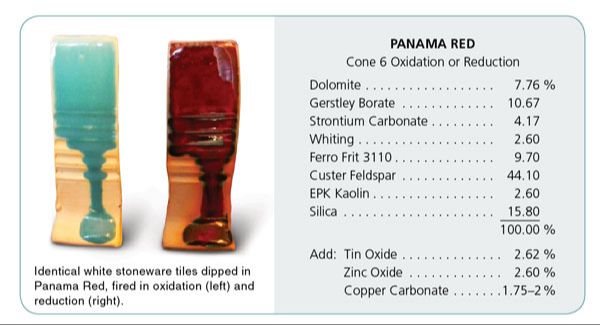

Reduction firing introduces additional gases into the kiln during firing to create certain chemical reactions and colors in the glaze. The kiln atmosphere is changed at peak temperature from oxidizing to reducing by limiting oxygen intake. Common reduction effects include darker colors, metallic sheen, or carbon trapping. This specialized technique requires careful control of the kiln atmosphere.

Raku Firing

Raku firing is a type of low-temperature reduction firing that involves removing pottery from the kiln while still glowing hot. The ware is placed in containers with combustible materials that create effects by altering the glaze. Raku pottery has unique crackled or metallic finishes. The fast cooling also creates distinctive shapes as the clay contracts. This spontaneous process means each raku piece is truly one-of-a-kind.

Achieving the Desired Result

Getting the right temperature, atmosphere, and duration of firing is critical for achieving the desired result with pottery. Each type of clay has an optimal firing range. For example, according to Soul Ceramics [1], while pure kaolin fires to maturity at 3272°F (1800°C), most porcelain should be fired between 2381°F and 2455°F (1305°C and 1346°C). Testing is required to determine the temperature that achieves the optimal fired strength for glazeless vitrified ceramics, as noted by Digital Fire [2].

The atmosphere inside the kiln, whether oxidizing or reducing, will also impact the finished look of the pottery. Oxidation produces brighter colors, while reduction can create earthier tones. Controlling the atmosphere requires knowledge of the clay, glazes used, and kiln capabilities.

Lastly, the duration of firing must match the clay body, glazes, and size of pieces to allow heat to fully penetrate the ware. Firing schedules provide guidelines for ramping up to top temperature and how long to soak at that peak temperature. Having an accurate programmer allows following the schedule precisely.

Achieving the right balance of time, temperature and atmosphere provides the best chance of firing pottery successfully with pleasing, durable results.

Convection vs Radiant Heat

Heat is transferred in a kiln through convection and radiant heat transfer. Convection involves the circulation of hot air, while radiant heat travels in a straight line from the heat source.

Convection occurs when the air inside the kiln is heated by the elements and rises, circulating around the ware. The motion of the hot air transfers heat to the surfaces of the clay pieces. Convection ensures even heating throughout the kiln chamber.

Radiant heat comes directly from the red-hot elements as infrared energy. It travels in a straight line to warm the ware directly, independent of air circulation. Radiant heat transfer is faster and more efficient than convection.

Both convection and radiant heat are necessary for uniform firing. Convection evens out hot spots, while radiant heat quickly brings the ware to temperature. The balance between the two depends on factors like kiln design and firing program. Understanding how heat transfers in a kiln helps achieve the desired results.

Electric vs Gas Kilns

When deciding between electric and gas kilns, there are several pros and cons to consider:

Electric kilns are generally easier to use, as they provide automatic control over the firing process. Many electric kilns come with digital controllers that allow you to program custom firing cycles. Electric kilns heat up and cool down at a steady rate, allowing for more precise firings. They are also cleaner and do not produce any fumes or smoke. However, electric kilns may be more expensive to purchase and operate due to higher energy costs. The max temperature is also typically lower than gas kilns.

Gas kilns can reach higher temperatures, making them suitable for firing stoneware and porcelain. The atmosphere inside a gas kiln can also be more easily controlled and manipulated for effects like reduction firing. Gas kilns fire up and cool down rapidly. However, they require ventilation and do produce some fumes. Gas kilns also require more manual monitoring and adjustment during the firing process. There is a higher danger of explosion with gas kilns if not properly maintained. Gas lines must be installed and kilns must be vented outside (1).

When choosing between electric and gas, factors like your preferred firing method, clay type, safety, costs, and convenience should be considered. Both types of kilns have pros and cons to weigh.

Fire Precautions

Firing pottery involves dealing with extremely high temperatures, so it’s crucial to take proper safety precautions. Here are some tips:

- Keep combustible materials like paper, solvents, and fabrics at least 3 feet away from the kiln during firing (Kiln Safety in Schools). Stray materials can easily catch fire in the intense heat.

- Wear fire-rated gloves when loading or unloading the kiln, as the ware and kiln surface get extremely hot (Kiln Safety Tips | How to Fire Safely and Effectively).

- Use protective eyewear when looking through peepholes to avoid burns. Also be cautious when removing plugs (Kiln Safety Tips | How to Fire Safely and Effectively).

- Have a fire extinguisher on hand and know how to use it properly.

- Make sure the kiln is on a stable, nonflammable surface.

- Monitor the kiln during firing and never leave it unattended for long periods.

Taking basic precautions goes a long way in preventing fires and injuries when firing pottery. It’s also a good idea to check local fire codes for any additional kiln safety regulations.

Common Firing Defects

There are several common firing defects that can occur during the pottery firing process. Understanding the causes of these defects can help potters avoid them in the future.

Cracking

Cracks in pottery can be caused by several issues during firing:

- Firing too quickly – temperature rises too rapidly and the clay cannot adjust fast enough, leading to cracks from thermal shock Source

- Insufficient drying – firing wet clay results in cracking as the water turns to steam in the kiln

- Overly thick sections – extra thickness can result in cracking from uneven drying and heating

- Incompatible materials – some clays and glazes expand/contract at different rates in the kiln, leading to cracks

Underfiring and Overfiring

Clay pots that are underfired or overfired exhibit defects like:

- Bisque still powdery – fired at too low a temperature so clay did not fully vitrify

- Glaze did not mature – signs of underfiring include dull colors and easily scratched glaze

- Bloating, deforming – firing too hot can make pieces expand and misshape

- Glaze defects like crazing, shivering, pitting

Scumming and Bloating

Scumming occurs when impurities in clay rise to the surface during firing. Bloating is the misshapen effect from gasses expanding clay and glaze when fired too hot.

Ways to avoid scumming and bloating include:

- Select pure clay and glaze materials

- Control kiln temperatures

- Fire according to clay and glaze specifications

- Fire bloat-prone materials slower, at lower temps

Conclusion

Firing is one of the most critical steps in creating durable pottery. Proper preparation of the kiln, careful loading of the ware, and selecting the appropriate firing method are key to achieving optimal results. Both convection and radiant heat kilns, as well as electric and gas options, have their advantages and disadvantages. Regardless of technique, strict temperature control and protection from drafts are essential for an even firing. Taking proper fire safety precautions is also critical, given the extreme heat involved. While the firing process may seem complex at first, mastering it is very achievable with care and experience. With an understanding of the options available and how variables like heat work and air flow impact the ware, ceramic artists can produce stunning pottery that withstands the test of time.