What Is The Difference Between Center Finder And Edge Finder?

Center finders and edge finders are two types of important tools used in machining and manufacturing. They serve different purposes in locating reference points, edges, and centerlines on workpieces. Understanding the key differences between center finders and edge finders is crucial knowledge for machinists, CNC operators, toolmakers, and other roles working with computerized or manual machine tools.

Being able to accurately determine the center or edge of a workpiece ensures precise alignment and positioning, which leads to higher quality finished products, less scrap, and improved efficiency. This article will provide an overview of both tools, explain their unique capabilities, compare their pros and cons, and offer usage tips for machinists to get the most out of center finders and edge finders in manufacturing workflows.

Definition of Center Finder

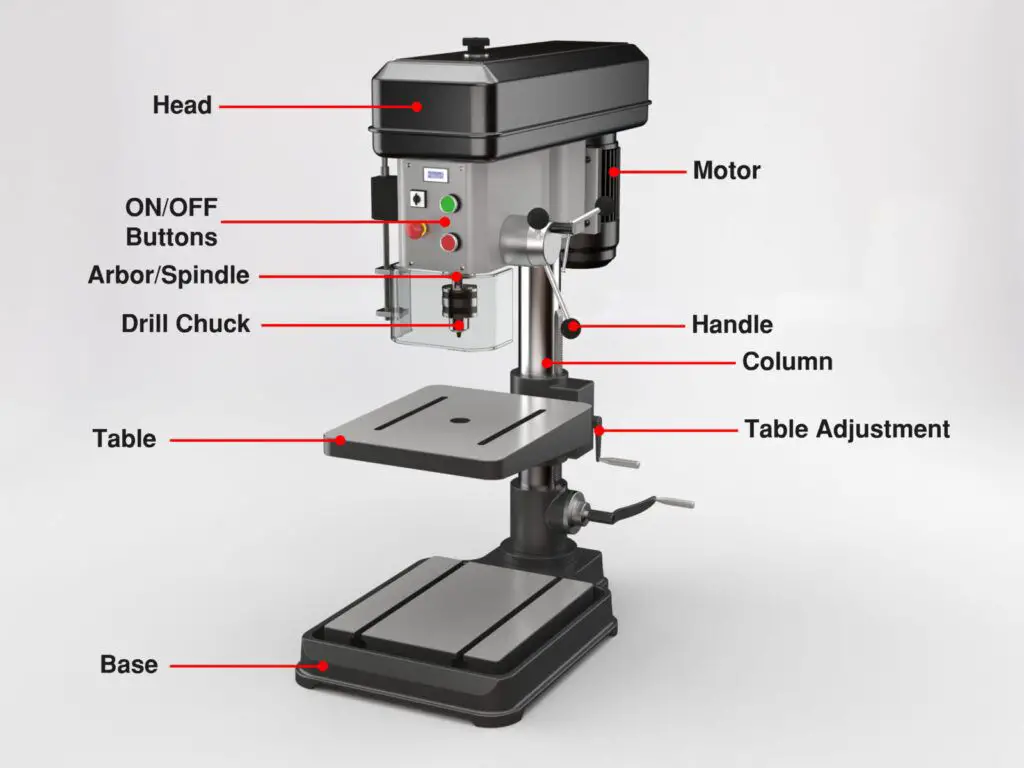

A center finder is a tool used with machine tools like drill presses and milling machines to help align the axis of the workpiece with the rotating spindle center of the machine. Center finders come in various designs but generally consist of a pointed tip mounted on an adjustable shaft. The tip is inserted into the pre-drilled starting center dimple or hole in the workpiece. The shaft of the center finder can then be adjusted so that the tip is precisely aligned with the machine’s rotating spindle center.

The purpose of using a center finder is to help position the workpiece accurately before machining operations like drilling, boring, or milling. Properly aligned centers between the workpiece and machine ensure the machined holes or features will be located correctly. Center finders save time and prevent errors by eliminating guesswork and repeated test cuts to find the workpiece center. They provide precision alignment for machining operations that require high accuracy and consistency.

Some key types of center finders include dead center finders, live center finders, and floating center finders. Each works a bit differently but achieves the same goal of aligning the workpiece to the machine’s axis (Source).

Types of Center Finders

Center finders come in a variety of types including mechanical, electronic, laser, and optical. Each has its own advantages and disadvantages.

Mechanical center finders are the most common and economical type. They typically consist of a pointed conical tip mounted in a cylindrical body. As the tip contacts the workpiece when moved in the X and Y axes, it displaces and provides a visual indication of the center point. Mechanical center finders require a skilled operator but work on any material.[1]

Electronic center finders use sensors and indicators to precisely locate the center. They emit a signal such as a beep or light when the exact center point is found, making them easier to use than mechanical types. However, electronic finders have limited battery life and do not work on nonconductive materials.[2]

Laser center finders project intersecting beams of light to pinpoint the center very accurately. They work on any material but are more expensive than other types.[3]

Optical center finders use a magnified reticule in an eyepiece to visually identify the center point. They provide high precision but can be difficult to use and have a relatively small range.

Overall, mechanical center finders offer a good balance of cost and functionality for most applications. Electronic and laser types provide greater ease of use and accuracy for critical center finding needs.

Definition of Edge Finder

An edge finder is a tool used in milling machines and CNC machines to accurately locate the edges of a workpiece. It consists of a precision ground shaft with a conical tip that protrudes slightly from the shaft. The shaft is spring loaded so the tip retracts when it contacts the edge of the workpiece (see How does an edge finder work?).

Edge finders operate using mechanical, electronic, or optical mechanisms. Mechanical edge finders are the most common and use the retracting motion of the tip to indicate when the edge is found. Electronic edge finders have sensors that detect when contact is made. Optical edge finders use LEDs and phototransistors to optically detect the edge.

The key use case of an edge finder is locating reference surfaces and edges to precisely position the workpiece. This allows the milling machine or CNC machine to accurately machine features in relation to the located edges. Edge finders are essential for machining parts to tight tolerances.

Types of Edge Finders

There are a few main types of edge finders:

- Mechanical edge finders – These are the most common type. They consist of a spindle that moves once contact is made with the edge of a workpiece. Common types include single-end, double-end, and gage pin mechanical edge finders. They rely on mechanical contact to locate edges.

- Electronic edge finders – These use sensors to electronically detect when the edge finder makes contact with an edge. They are very accurate and fast but also more expensive than mechanical types. Some incorporate strain gauges while others use optical sensors.

- Optical edge finders – These use a laser or LED light source and camera to optically detect edges by changes in light reflection. They provide non-contact edge detection and can achieve very high precision.

- Pneumatic edge finders – These direct blasts of air toward the workpiece and sense changes in air pressure or flow when contact is made with an edge.

Most edge finders are designed for milling applications to locate the edges of workpieces, though some special types are made for turning machines. The different types vary in accuracy, speed, and cost.

References:

[Edge Finders Selection Guide: Types, Features, Applications](https://www.globalspec.com/learnmore/manufacturing_process_equipment/machine_tool_accessories/edge_finders)

Key Differences

Center finders and edge finders are similar but have some key differences in how they operate and are used:

Operation:

- Center finders have a sharp conical tip that finds the center of a divot or existing hole. They can accurately locate the center point. Edge finders have a cylindrical body with a conically-tapered tip that finds the edge of a workpiece when the body and tip contact the edge at the same time.

Precision:

- Center finders are capable of more precision (repeatability within 0.005″) since they are locating an existing center point. Edge finders have more variance (repeatability within 0.01″) since they depend on the user detecting when both the body and tip touch the edge.

Use cases:

- Center finders are best for locating the center of an existing hole or divot. Edge finders are better for finding the edge of an undefined workpiece or finding the edges in relation to the spindle.

According to CNC Cookbook, edge finders are one of the most frequently used tools for basic CNC machining setups. Center finders have more specialized usage for getting precise center locations.

Pros and Cons

Both center finders and edge finders have their own unique advantages and disadvantages in use.

Some key pros of using a center finder include:

- Very accurate at finding the center of a hole or cylinder (Source)

- Can work on deep holes unlike edge finders (Source)

- Useful for centering workpieces in lathes or dividing heads (Source)

Some disadvantages of center finders include:

- More specialized tool with limited uses

- Can be more expensive than basic edge finders

- Require a skilled operator for best results

Advantages of using an edge finder include:

- Simple and easy to use even for beginners

- Very affordable basic models

- Quickly locates edges and surface boundaries

Potential disadvantages of edge finders:

- Less versatile than center finders

- Difficult to use on convex/concave surfaces (Source)

- Less precision than quality center finders

Overall, center finders excel at specialized centering tasks while edge finders are a more affordable and simple edge/boundary locating tool. The choice depends on the specific use case and operator skill level.

Usage Tips

Here are some tips for properly using an edge finder and center finder to get accurate results:

- When using an edge finder, make sure to zero it on a known datum or edge before attempting to find the edge of your workpiece. Gently roll the edge finder along the edge rather than stabbing at it to get the most accurate reading. Move slowly and watch for the needle to settle before locking in your reading.

- With a center finder, take light cuts and peck to prevent bending the slender tip. Rotate the tool before each peck to distribute wear evenly around the tip. When nearing the center, take very small cuts (0.001″ or less) to precisely locate the midpoint.

- Keep both tools sharp, clean and free of chips, dirt or nicks. Dress any burrs or imperfections with a fine India stone.

- Allow the machine spindle and edge/center finder to reach thermal equilibrium before beginning critical measurements.

- Avoid excessive hangout length with either tool. Keep the shank as short as practical.

- Use a drill chuck rather than collet for better concentricity and minimal runout.

- Make sure the machine head is trammed properly in all axes.

Following these tips will help machinists get the highest accuracy from their edge finders and center finders.

Cost Comparison

When comparing costs, center finders tend to be less expensive than edge finders. A basic mechanical center finder can be purchased for around $5-15, while more precision models with digital readouts cost $50-100. On the other hand, basic mechanical edge finders start around $20-30, while precision digital models run $100-300+.

For example, on MSC Direct, a general purpose mechanical center finder is priced at $13.57. Meanwhile, their mechanical edge finder with a pointed tip is $28.65. So the edge finder is more than double the cost.

The cost differential holds up even when comparing premium digital models. Starrett’s digital readout center finder is $99, while their digital edge finder is $259. So again, the edge finder costs significantly more.

The reason for the price difference is likely the additional precision and capabilities built into edge finders. Their pointed tips can locate edges more accurately. Overall, the extra features and precision of edge finders justify their higher cost for machines where accurate edge location is critical.

Conclusion

The key differences between center finders and edge finders come down to their specific purposes. Center finders are used to locate the exact center of a workpiece in order to properly center it for machining operations. They utilize a specialized pointed tip that allows them to find the central axis or rotational center. Edge finders meanwhile are designed to locate the edges or outside dimensions of a workpiece in preparation for cutting operations. They use a roller tip which contacts the edges without damaging them.

In general, center finders will be used first to find the centerpoint and get the workpiece properly aligned on the machine. Edge finders come after to delineate the boundaries and provide the necessary information for cutting to the proper dimensions. Center finders are indispensable for centering round stock or holes, while edge finders really shine for mapping rectangular stock and establishing the vise position. Being familiar with both tools and when to use each one can greatly improve machining efficiency and precision.