What Is The Difference Between Cuo And Cu2O?

Introducing Copper Oxides

Copper oxides are inorganic compounds that contain copper and oxygen. The most common copper oxides are copper(I) oxide (Cu2O) and copper(II) oxide (CuO). Copper oxides have been studied extensively due to their importance in many applications including catalysis, solar cells, batteries, and gas sensors (https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6339020/).

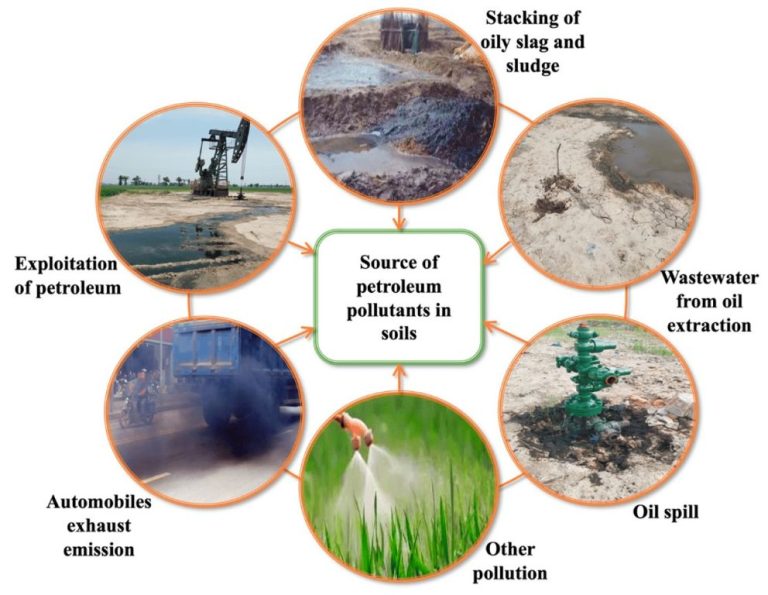

Copper oxides exhibit unique optical, electrical, and magnetic properties that make them useful for a variety of applications. For example, copper oxides are p-type semiconductors, meaning they have positive charge carriers. This property allows them to be used in diodes, transistors, and photovoltaic devices. Additionally, copper oxides demonstrate photocatalytic activity under visible light irradiation, making them useful for breaking down organic pollutants in water treatment. Their piezoelectric properties allow them to convert mechanical stress into electric charge, which can be used for power generation.

Overall, copper oxides are an important class of materials due to their versatility. Their unique properties have enabled applications in clean energy, electronics, environmental remediation, and more. Continued research aims to further develop copper oxides and related materials for existing and emerging technologies (https://shop.elsevier.com/books/copper-oxides-and-related-materials/sagadevan/978-0-443-13872-0).

Chemical Composition

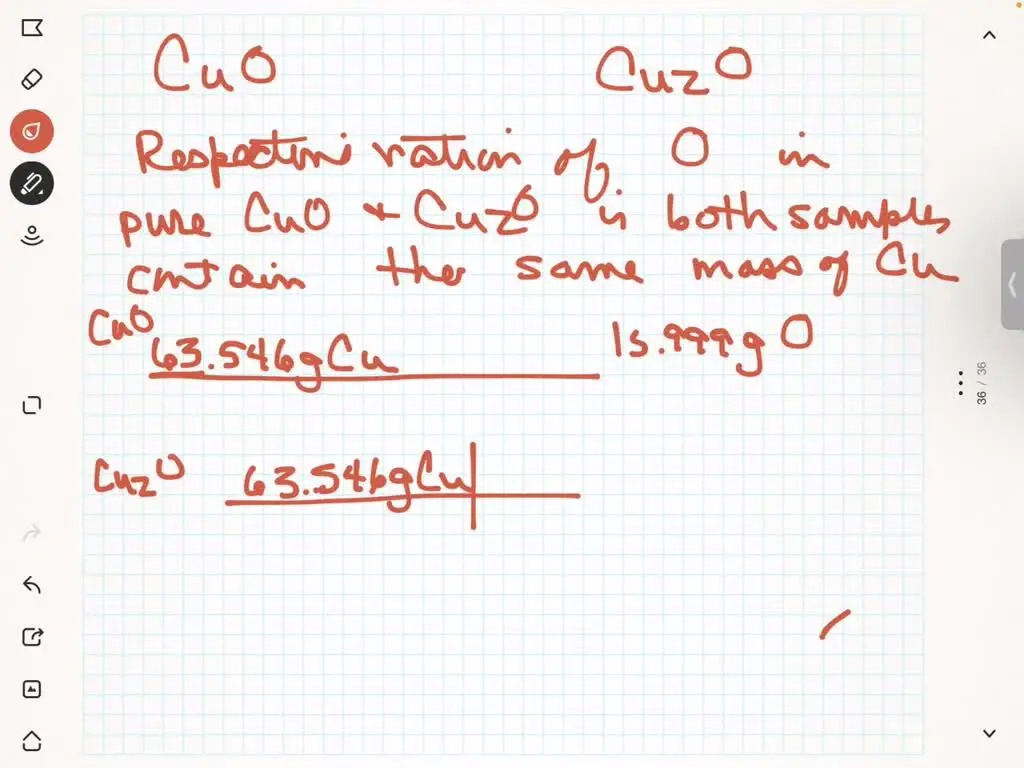

The key difference in the chemical composition of cupric oxide (CuO) and cuprous oxide (Cu2O) lies in the different ratios of copper to oxygen atoms.

CuO has a 1:1 ratio of copper to oxygen. Its chemical formula is CuO, indicating one copper (Cu) atom bonds to one oxygen (O) atom.

In contrast, Cu2O has a 2:1 ratio of copper to oxygen. Its chemical formula is Cu2O, indicating two copper atoms bond with one oxygen atom.

The differing copper-to-oxygen ratios give the two oxides distinct physical and chemical properties, which lead to different applications.

Physical Properties

Copper(I) oxide (Cu2O) is a reddish solid with a cubic crystal structure. It has a density of 6.0 g/cm3 and a melting point of 1,232°C. In contrast, copper(II) oxide (CuO) is a black solid with a monoclinic crystal structure. It has a higher density of 6.3-6.49 g/cm3 and a much higher melting point of 1,326°C (source). The different colors and crystal structures of Cu2O and CuO can be attributed to their differing electronic structures and chemical bonding.

Electronic Structure

The electronic structures and resulting properties differ significantly between CuO and Cu2O. Cu2O is a p-type semiconductor with a direct band gap of 2.17 eV, allowing for applications in solar energy and optoelectronics (Wang, 2016). In contrast, CuO is an indirect band gap semiconductor with a smaller band gap of 1.2-1.9 eV, giving it a more metallic, conductive nature (Heinemann et al., 2013).

The valence bands of both CuO and Cu2O are formed by hybridized O 2p and Cu 3d orbitals. However, in Cu2O the conduction band minimum is comprised of Cu 4s states, while in CuO it is derived from Cu 3d states resulting in the differing band gaps (Heinemann et al., 2013). The larger band gap and direct transition in Cu2O make it the superior material for applications like solar cells, photodetectors and LEDs.

Chemical Properties

The chemical properties of CuO and Cu2O nanoparticles are determined by their reactivity and redox behavior. CuO is an oxide of copper with a +2 oxidation state and has a bandgap of 1.2 eV. It can be reduced to metallic copper or Cu2O. Cu2O contains Cu+ ions and has a bandgap of 2.1 eV. It can be oxidized to CuO or reduced to metallic copper. The different oxidation states lead to different reactivities.

CuO exhibits basic character and can react with acids to form salts. For example, it reacts with sulfuric acid to form copper sulfate:

CuO + H2SO4 → CuSO4 + H2O

CuO can also be reduced by hydrogen gas to produce copper metal:

CuO + H2 → Cu + H2O

Cu2O is amphoteric and reacts with both acids and bases. With dilute acids, it forms copper salts like CuSO4. With concentrated bases, it forms copper complexes like [Cu(OH)4]2-. Cu2O can be easily reduced to copper metal using a reducing agent like glucose:

Cu2O + C6H12O6 → 2Cu + C6H12O6 + H2O

The chemical reactivity and redox properties of copper oxides allow them to be used in applications like gas sensing, catalysis, solar energy conversion and electronics.

Preparation Methods

Several common synthesis routes exist for preparing CuO nanoparticles:

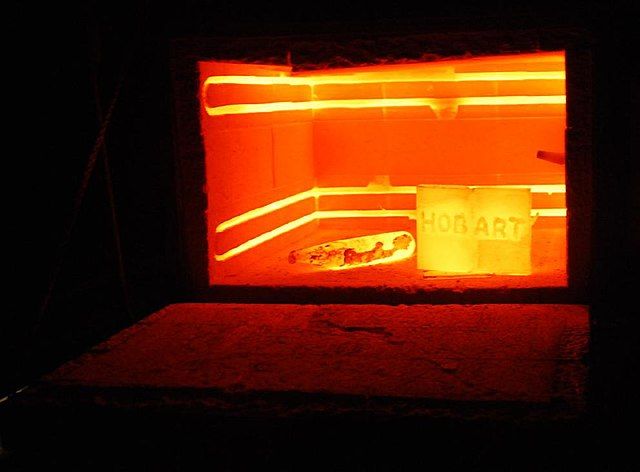

CuO nanoparticles can be synthesized by thermal decomposition of copper hydroxide precipitates. This involves adding a base like sodium hydroxide to an aqueous solution of a copper salt like copper nitrate, resulting in the precipitation of copper hydroxide. The copper hydroxide is then washed, dried, and calcined at 300-600°C to decompose it into CuO particles (Gupta et al., 2018).

A sol-gel technique can also produce CuO nanoparticles. This starts with a solution containing a copper salt and citric acid. The solution is heated to form a gel, which then undergoes aging, drying, and annealing at 300-500°C to form CuO particles with good crystallinity (Gupta et al., 2018).

CuO nanoparticles are also commonly synthesized through thermal oxidation of copper metal foil or plates. The copper substrate is annealed at high temperatures (500-1000°C) in air or oxygen atmosphere. This oxidizes the surface and leads to formation of CuO nanosheets or nanowires growing off the surface of the foil (Zhang et al., 2006).

Several methods also exist for producing Cu2O nanoparticles:

Cu2O nanocrystals can be prepared through reduction of copper salts. Copper acetate or copper sulfate is combined with sodium hydroxide and a reducing agent like glucose or ascorbic acid and heated to 60-100°C. The copper ions are reduced to Cu2O nanoparticles (Zhang et al., 2006).

Thermal decomposition of copper-containing precursors like copper formate or copper citrate in organic surfactants can also generate nearly monodisperse Cu2O nanospheres. The precursor salts decompose around 200°C to nucleate the Cu2O particles (Zhang et al., 2006).

Electrochemical techniques are another route to Cu2O nanoparticles. Applying a current across two copper electrodes in an electrolyte solution causes oxidation of the anode into Cu2O nanocrystals which can be collected (Nanotrun, n.d.).

Applications

CuO and Cu2O have different properties that make them useful for various applications. CuO has a smaller band gap than Cu2O, making it useful for applications like solar energy absorption and photocatalysis. CuO is also used as a pigment in ceramics and glass, and as a catalyst for chemical reactions like methanol synthesis. Its ability to readily donate oxygen also makes CuO useful for gas sensing applications.

Cu2O has a wider band gap than CuO, making it useful for applications that require visible light absorption like photovoltaics and photodetectors. The optical transparency of Cu2O in the visible spectrum enables applications in smart windows. Cu2O also has antibacterial and antifungal properties, making it useful for applications like food packaging and biomedical implants. The nontoxic nature of Cu2O is also advantageous for applications involving human contact.

In summary, the key applications of CuO include solar absorption, gas sensing, catalysis, and pigments. Cu2O is commonly used in photovoltaics, smart windows, antibacterial coatings, and other applications requiring visible light properties, transparency, and biocompatibility.

Environmental Considerations

Both CuO and Cu2O nanoparticles can have negative impacts on the environment if not properly disposed of or contained. According to a study by Ramskov et al. (2014) published in Aquatic Toxicology, CuO nanoparticles were found to be toxic to a variety of aquatic organisms. The toxicity was found to be shape-dependent, with rod-shaped particles being more toxic than spherical ones.

Proper disposal of copper oxide waste is important to prevent release into the environment. Incineration or recycling of spent CuO or Cu2O may be preferable to landfilling. According to Akter et al. (2021), synthesis methods that utilize green or environmentally-friendly approaches should be prioritized when producing copper oxide nanoparticles.

Cost Analysis

CuO and Cu2O have different relative production costs due to their different chemical properties and preparation methods. According to sources, Cu2O currently costs around 8,380 USD per metric ton in the Middle East market. In comparison, CuO costs less at around 5,600 USD per metric ton according to pricing data from chemical suppliers. This shows CuO has a lower production cost than Cu2O.

Some factors that affect the costs of these copper oxides include the costs of the raw materials and energy inputs needed for their production, as well as processing, transportation, and waste management expenses. For example, Cu2O is produced from copper metal, whereas CuO can be produced by heating copper hydroxide. So the costs of the raw copper and chemical inputs impact the overall production costs. Furthermore, their different chemical reactivities and required processing conditions, such as temperature and equipment needs, contribute to the differing costs of manufacturing each substance.

Overall, market pricing data shows that CuO has a lower production cost compared to Cu2O primarily due to differences in their preparation methods and chemical reactivities. However, costs fluctuate depending on raw material expenses, processing needs, and other economic factors.

References:

Copper Oxide Prices | Current and Forecast

Conclusion

In summary, the key differences between CuO and Cu2O are their chemical composition, structure, properties, and applications. CuO contains copper in a +2 oxidation state whereas Cu2O contains copper in a +1 oxidation state. This results in different electronic structures and properties such as bandgap and conductivity. CuO has a monoclinic structure while Cu2O has a cubic structure. In terms of applications, CuO is used more widely as a pigment and in solar cells, batteries, and gas sensors due to its narrower bandgap. Cu2O is used in some niche applications like photocatalysis. While both copper oxides have their advantages, CuO seems to have more versatility in terms of commercial applications. However, Cu2O may hold promise for specialized uses with further research and development. When selecting between these two copper oxide materials, the specific application and desired properties should guide the decision.