Can You Heat Treat A Knife Without A Forge?

Heat treating is an essential process for knives that involves heating and cooling the steel under controlled conditions to alter its properties. Specifically, heat treating strengthens the knife, maintains its durability through sharpening, and prevents it from breaking. This is extremely important for knives which undergo a lot of wear and tear. Traditionally, heat treating is done using a forge – a furnace powered by charcoal, coal or gas that can reach high temperatures to heat metal. However, not everyone has access to a forge. This article will explore different methods of heat treating knives without using a specialized forge.

Purpose of Heat Treating Knives

The purpose of heat treating a knife is to harden and strengthen the blade steel through controlled heating and cooling processes. Proper heat treatment transforms the molecular structure of the steel to make it significantly harder than in its original state (source). This hardening improves the blade’s edge retention, making it stay sharper for longer with use. It also makes the edge more durable and resistant to chipping or deforming. Additionally, heat treating can refine and modify other properties like corrosion resistance depending on the specific processes used.

By carefully controlling the temperature ranges and cooling rates during heat treatment, knife makers can achieve an optimal balance between hardness and toughness for the blade’s intended function. A properly heat-treated knife blade will better withstand repeated cutting tasks and hold its sharp edge longer between sharpenings. The transformed microstructure also strengthens the knife steel against impact forces that could potentially cause chips or cracks. Overall, heat treating allows knife makers to customize the hardness, durability, and cutting performance of the blade based on how it will be used.

Traditional Heat Treating with a Forge

A forge is a type of furnace used for heating metals to high temperatures to modify their physical properties like hardness. A metal is heated in the forge until it reaches a target temperature depending on the steel, then quickly cooled or “quenched” to harden the metal.

The basic steps for heat treating a knife using a forge are:

- Heat the forge to around 2000°F (1093°C). Many knifemakers use propane or charcoal forges.

- Place the knife blade in the forge once it reaches temperature. Leave it until the steel glows red, around 1450-1500°F (788-816°C) for high carbon steels.

- Quickly move the red hot knife from the forge to a quenching medium like oil or water. This rapidly cools the steel to harden it.

- Temper the blade after quenching by placing it in an oven at 350-400°F (177-204°C) for 2 hours. This reduces brittleness.

Proper heat treating requires carefully controlling temperatures and timing when heating, quenching, and tempering. A forge provides high stable temperatures ideal for the initial heating stage.

Heat Treating without a Forge

While a forge is the traditional and most effective way to heat treat knives, there are some alternative methods for those without access to a forge. These include using an oven, torch, or hot plate to apply focused heat to the blade. However, there are some precautions and challenges to be aware of.

When using an oven, temperatures can be inconsistent, so the blade must be moved around to evenly distribute heat. Ovens also may not reach ideal hardening temperatures above 1400°F. Precise temperature control is important to avoid overheating. Using a torch allows directing the flame precisely, but maintaining an even temperature across the blade is difficult. With a hot plate, temperature regulation and distribution are also challenges. Cooling the blade quickly after heating is crucial for any method.

No matter the technique, proper safety gear like heavy gloves and eye protection are a must. Have a quenching medium like oil ready before heating the steel. Research target temperatures and quenching times for the specific steel. Work slowly and methodically, normalizing and annealing before hardening. With care, focus, and patience, it is possible to heat treat blades effectively without a forge.

Oven Method

The oven method utilizes a standard kitchen or household oven to heat treat and temper knives. It provides an accessible option for knifemakers without a dedicated forging setup.

To heat treat a knife in the oven:

– Pre-heat oven to 750-800°F. Use a high temp oven thermometer to monitor.

– Place knife in oven for 15-20 minutes until austenitizing temperature is reached.

– Quickly remove and quench in oil or other medium. This rapidly cools the steel.

– Temper the knife by placing it back in oven at 375-450°F for 1-2 hours. Repeat 2-3x.

– Allow knife to cool slowly.

The key is bringing the steel up to critical temperature using the oven, then quickly quenching. Ovens allow control and even heating. Recommended quench oils include parks 50 or canola oil. Multiple temper cycles help reduce brittleness and improve toughness.

Source: https://www.redlabelabrasives.com/blogs/news/how-to-heat-treat-a-knife

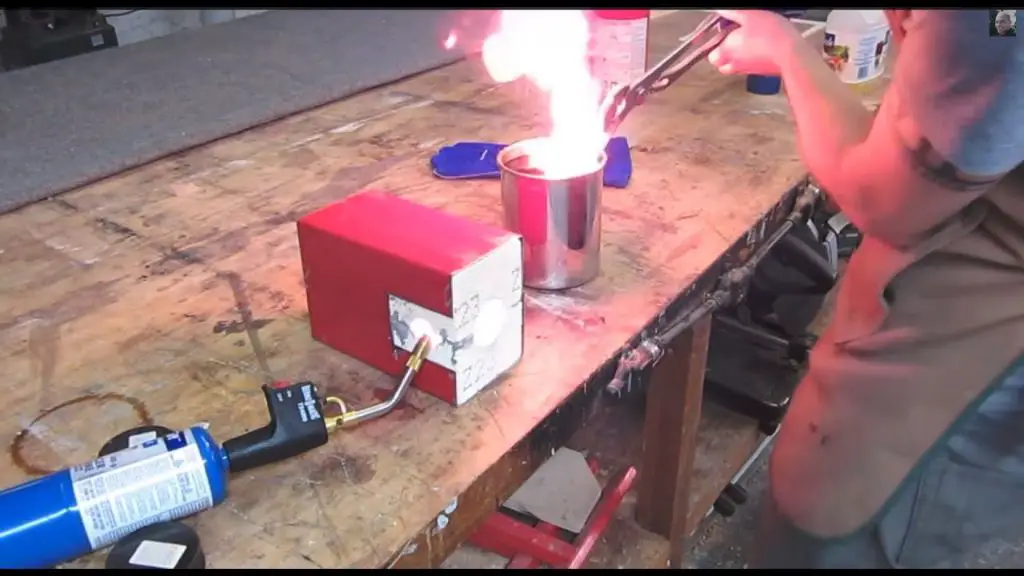

Torch Method

One of the most accessible methods for DIY knife makers is using a torch to heat treat blades. You’ll need a MAP gas or propane torch that can reach high temperatures. Make sure the tank is full and the torch is in good working condition before starting.

The basic process is:

- Secure the knife blade in a clamp or vise.

- Use the torch to evenly heat the blade until it reaches critical temperature (around 1500°F for high carbon steels like 1095). The metal will start to glow red when it approaches critical temperature.

- Once at critical temperature, quickly quench the blade in an oil bath to rapidly cool it.

- Temper the blade by reheating it to a lower temperature like 400°F. Allow it to cool slowly.

Temperature control can be tricky with a torch. Too hot and you risk overheating the steel which ruins the heat treatment. Too cold and the steel won’t properly harden. Using temperature indicating crayons like Tempilaq can help identify when you’ve reached the right heat range [1]. Going slowly and evenly heating the blade can also help avoid overheating sections.

Hot Plate Method

Using a hot plate is an accessible way to heat treat knives at home without a forge. Hot plates allow for even heat distribution and good temperature control. Some advantages of using a hot plate include:

– Available in most homes or inexpensive to purchase

– Provide even, consistent heating of the blade

– Allow control over temperature settings

– Safer than an open flame torch method

To heat treat a knife using a hot plate:

1. Secure the knife in place on the hot plate, using firebricks or high heat mortar to prop it up.

2. Pre-heat the hot plate to the desired temperature, around 1500-1550°F for high carbon steel.

3. When the temperature stabilizes, place the knife blade directly on the hot plate surface and heat until glowing red, about 10 minutes.

4. Quickly move the red hot knife to your quenching medium, like oil or water, until cooled.

5. Temper the knife in an oven heated to around 350°F for 2 hours to reduce brittleness.

Regulating the hot plate temperature is crucial, so use a thermometer probe to monitor it. Turn the hot plate off periodically to maintain the ideal heat range. With some practice, a hot plate can be an effective way to heat treat knives at home.

Other Methods

There are some other creative methods for heat treating knives without a forge, including using an induction heater, sandwich press, or even the sun:

Induction heaters use electromagnetic induction to quickly heat metals like steel. They allow precise control over temperature, but require special equipment. According to this source, they are one of the best methods for heat treating knives at home without a forge.

A sandwich press or waffle iron can also be used to apply heat to a knife blade for short periods. The advantage is that many people already own one. However, temperature control is limited and you have to work in short bursts to avoid overheating parts of the blade, according to this overview.

Some people even recommend using focused sunlight, such as through a magnifying glass or bellows. This takes patience and has very limited temperature control, but demonstrates how many options are possible with some creativity.

Overall, induction heating and ovens tend to offer the best balance of precision and accessibility for heat treating knives at home without a real forge.

Best Practices

When heat treating knives without a forge, there are some important best practices to follow for safety and optimal results:

Safety considerations:

- Wear protective gear like heat-resistant gloves, apron, and eye protection.

- Work in a well-ventilated area to avoid inhaling fumes.

- Secure the knife properly so it doesn’t move around.

- Allow the knife to cool fully before handling to avoid burns.

Getting optimal results:

- Use an accurate laser thermometer to monitor temperatures.

- Heat the knife evenly to avoid warping.

- Quench the blade quickly and uniformly after heating.

- Temper the knife immediately after quenching while the steel is still hot.

Common mistakes:

- Overheating or underheating the blade.

- Quenching the knife unevenly, causing cracks.

- Not tempering the knife, resulting in a brittle blade.

- Letting the knife air cool instead of quenching.

- Not normalizing the grain structure before hardening.

Following proper procedures and monitoring temperatures closely will help avoid these errors and produce a strong, durable blade.

Conclusion

This article has explored the different methods of heat treating knives without the use of a traditional forge. While a forge is the ideal tool for knife heat treating, it is possible to effectively heat treat blades at home using common household items like an oven, torch, or hot plate. The oven method provides even heat and easy temperature control but takes a long time. Torches allow precise heating of the blade but require practice to master. Hot plates offer an inexpensive option but temperature regulation can be difficult. Regardless of the heat source, following proper procedures like normalizing, quenching, tempering and sanding is key to creating a strong, lasting edge.

For readers interested in heat treating knives at home without a forge, the oven or hot plate methods are likely the easiest way to start out. Invest time in learning the right temperatures and heating times for the steel being used. Work slowly and safely, have quenching oil ready, and don’t overheat the metal. With some practice, it’s possible to achieve professional-level results. While the process takes patience and care, heat treating your own knives can be incredibly rewarding.