Does Terracotta Clay Need To Be Fired?

What is Terracotta Clay?

Terracotta clay, sometimes written as Terra cotta, is literally translated in Italian as ‘fired earth’ (https://www.soulceramics.com/pages/what-is-terracotta-clay-made-of). It is an ancient building material made from natural clay that is molded and then baked at high temperatures in a process known as firing. This gives the clay strength and durability.

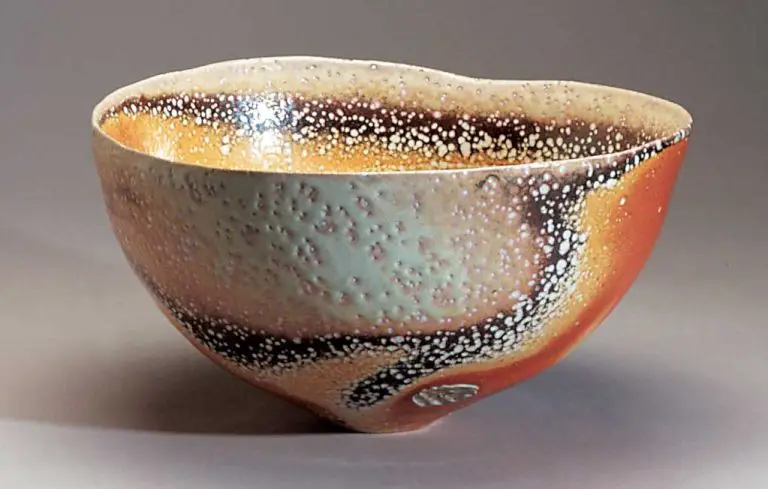

Terracotta clay is commonly used for making flower pots, sculpture, pipes, bricks, tiles and vases (https://www.wonderopolis.org/wonder/what-is-terracotta). It has a distinct reddish-orange color due to the iron oxide content in the clay. Terracotta is porous and absorbent yet weather resistant. It is affordable, readily available and easy to work with.

The properties that make terracotta useful include its porosity, durability, affordability and low shrinkage. When fired at high temperatures, terracotta becomes hardened while still remaining breathable and absorbent. The low shrinkage allows terracotta pieces to retain their shape and details. With proper sealing, terracotta can withstand harsh weather conditions and last for decades if not centuries.

Firing Process for Clay

The firing process is a fundamental step in producing pottery and ceramics. According to Ceramic Arts Network, firing causes important physical and chemical changes in clay that permanently alters it into a solid, durable material (https://ceramicartsnetwork.org/daily/article/Firing-Clay-The-Lowdown-on-the-Ceramic-Firing-Process).

Firing happens in a kiln, an oven-like device for firing pottery, at high temperatures ranging from 1,800°F to over 2,300°F. At these high heat levels, several changes occur in the clay:

- First, firing evaporates all moisture from the clay.

- Next, at around 1,000°F, clay particles vitrify, which fuses them into a hard, permanent ceramic material.

- At higher temperatures from 2,100°F–2,300°F, the clay melts and glass forms within the body, creating stoneware and porcelain.

These fired clays become non-porous, rock-hard finished ceramics. The process leaves the clay permanently hardened, able to withstand water and daily use without deforming.

Why Fire Clay?

Firing clay serves several important purposes that make the finished ceramic much more durable and functional than unfired clay. The three main reasons to fire terracotta clay are to strengthen it, waterproof it, and give it a permanent finish.

The firing process chemically alters the clay through sintering, which fuses the clay particles together to create a stronger, denser material. According to the Ceramic Arts Network, as clay vitrifies during firing “the silica in the clay begins to melt, filling the pores and gap between particles, which in turn makes the clay less porous and more durable” (source). The higher the firing temperature, the more durable and rock-like the clay becomes.

Firing also makes terracotta waterproof by closing its pores and limiting water absorption. Unfired clay remains quite porous and would disintegrate if saturated with water. Proper firing vitrifies the clay so it can withstand moisture without degrading.

Finally, firing provides a permanent finish to the clay. The transformation during firing is irreversible, so fired ceramics maintain their structure and durability. According to Wikipedia, firing “permanently hardens the clay beyond its initial air-dried state” (source). The firing process locks in the strength and water resistance.

Types of Unfired Clay

There are several common types of unfired clay used in art and pottery:

Greenware refers to clay objects that have been shaped but not yet dried or fired. Greenware contains moisture and is in a soft, pliable state. It must be handled carefully to avoid deformation. Once allowed to air dry fully, greenware becomes easier to work with before firing. Some clays can be fired in the greenware state for certain effects.

Air-dry clay is clay engineered to harden without being fired. It contains other materials besides pure clay that help it cure and harden at room temperature as the moisture evaporates. Air-dry clay is popular for crafts, clay modeling, and decorative objects. It does not become water-resistant and has lower durability than fired clay unless sealed. Common types include polymer clay, cold porcelain, Cernit, and paper clay.

Polymer clay contains no real clay minerals. It is made from polymers like PVC mixed with coloring pigments and other ingredients. Polymer clay can be shaped when soft, then baked at low temperatures to harden it through polymerization, the molecules linking via chemical bonds to form a plastic material. Polymer clay is very versatile for arts and crafts as it does not require a kiln for hardening.

Sources:

https://artabys.com/unfired-clay/

https://www.artmolds.com/clay-types

Using Unfired Terracotta

Terracotta clay does not need to be fired in order to be used for certain purposes. Some common uses of unfired terracotta include:

Temporary sculptures – Unfired terracotta can be used to create temporary sculpture pieces or models. The clay remains soft and malleable even when dry, rather than becoming brittle like fired clay. This allows artists to shape and reshape unfired sculptures as desired. Unfired clay sculptures are very fragile and not meant to last permanently.

Craft projects – Unfired terracotta is popular for simple arts and crafts projects. It can be molded into shapes, imprinted with textures, or hand-painted. Unfired clay crafts should be handled gently since they do not gain strength from firing. They also cannot be made water-resistant without a sealant.

Modeling – Unfired terracotta is an ideal material for preliminary modeling and prototyping. It can be used to create concept models that capture an initial design idea. Model-makers appreciate the ability to continually modify unfired clay as they evaluate the design.

Pros of Not Firing

There are several advantages to using unfired terracotta clay rather than fired clay:

Unfired clay requires less time to work with. Since there is no kiln firing required, projects made with unfired clay can be completed much more quickly compared to fired clay pieces.

Working with unfired clay is also lower cost than fired clay. The firing process requires significant energy, equipment, and labor expenses that are avoided when working solely with air-dried clay. Firing kilns are expensive to purchase and operate.

Unfired terracotta clay remains porous after drying. This means it can absorb and release moisture, helping regulate humidity in certain applications. Fired clay becomes vitrified, so it no longer retains the natural breathability of raw clay.

Cons of Not Firing

One of the main cons of not firing terracotta clay is that the unfired pieces are less durable and tend to be more fragile than fired ceramic pieces. When clay is fired, it undergoes a chemical change that permanently hardens and strengthens the material. Unfired clay remains quite soft and porous (Artabys). This means unfired sculptures and pottery are more prone to chipping, cracking, and breaking if handled roughly or exposed to extreme temperatures.

Another drawback is that unfired terracotta is water soluble. The clay particles have not been permanently fused together through firing, so water can still penetrate the terra cotta and cause the sculpture or vessel to slowly disintegrate. Even brief exposure to water or moisture in the air can damage and degrade unfired clay over time. Fired ceramics, on the other hand, are generally waterproof.

Finally, unfired clay art tends to be more temporary in nature compared to fired ceramics that will last for generations. Unfired clay has a high risk of becoming damaged, ruined, or decomposed since it remains quite soft and porous. So unfired pieces normally don’t stand the test of time as well (Quora). The firing process permanently hardens and preserves the clay.

Tips for Unfired Clay

When working with unfired terracotta clay, there are some useful tips to follow in order to help preserve the artwork:

Seal it: Applying a sealant can help protect unfired clay pieces from damage. Polyurethane, acrylic mediums, and waxes can be used to seal the clay’s porous surface. Multiple thin layers of sealant are recommended for best results. Allow each coat to dry fully before adding the next layer for maximum durability and protection.

Handle carefully: Unfired clay is fragile, so handle pieces with care to avoid chipping or cracks. Avoid touching areas that protrude or parts that can easily break. Move pieces slowly and support all sides and bottom when transporting.

Sheltered display: Since unfired clay never reaches the high temperatures of traditional ceramics, it remains quite sensitive to the elements. Avoid moisture and direct sunlight which can weather, erode, and deteriorate the clay over time. Instead, display unfired pieces indoors or under a covered area for protection.

When to Fire Terracotta

There are certain cases where it is recommended to fire terracotta clay to improve its durability and functionality:

For permanent sculptures or installations meant for outdoor use, firing terracotta is highly recommended. The firing process vitrifies and waterproofs the clay, protecting it from damage caused by weather and moisture over time. Unglazed, unpainted terra cotta can last for centuries if fired properly.

Functional pottery such as vases, mugs, and plates should be fired before use. The firing process hardens and strengthens the clay, making it more durable and able to withstand repeated use. Unfired clay is prone to chipping, cracking, and even disintegrating when subjected to the stresses of normal use. Firing allows functional pieces to be washed, used, and enjoyed for years.

In some cases, very low-fire terracotta may be suitable for non-functional decorative objects meant for indoor use. However, firing provides much better durability and is recommended for any terra cotta pieces meant to last more than a few years. Consult glaze manufacturer instructions for recommended firing temperatures.

Conclusion

As we’ve discussed, firing terracotta clay is beneficial as it makes the clay more durable, water-resistant, and less prone to cracking or chipping. However, for certain applications where the clay is not exposed to weather, water, or long-term continuous use, unfired terracotta may be suitable.

In summary, the key points made in this article are:

- Firing terracotta clay hardens it through sintering and vitrification, making it less porous.

- Unfired terracotta is prone to crumbling and damage when exposed to water or changes in temperature and humidity.

- Fired terracotta is ideal for functional items like planters, dishes, sculptures etc. that need to withstand weather and continuous handling.

- Unfired terracotta can be used for short-term decorative objects or non-functional art.

In conclusion, I recommend firing any terracotta items that will be utilized frequently, exposed to the elements, used to hold water, or expected to last a long time. For one-time decorative uses, unfired terracotta may be suitable, but it’s advisable to apply a sealant. Evaluate the application and intended lifespan of the terracotta piece to determine if firing is recommended or not.