How Did The Romans Make Pottery?

Pottery was an important part of daily life and commerce in ancient Rome. From cooking pots to tableware, storage jars, lamps, and building materials, ceramic vessels and objects were ubiquitous across the Roman Empire. The Romans became masters in shaping clay and applying decorative designs. Roman pottery reflected advancements in art, technology, cooking, trade, and wealth, and had a lasting influence on European kitchens and table culture.

Roman pottery progressed through several stages in its over 1000-year history, starting with basic unglazed earthenware in the early Republic, evolving to sophisticated glazed and decorated wares by the 1st century, peaking with mass-produced fine wares and specialty items between the 1st-3rd centuries, and then declining in diversity and quality in the later Empire. Even today, archeologists unearth thousands of ancient Roman ceramic fragments, which offer insights into Roman culture and society.

Clay Sources

The Romans obtained clay from various sources. According to Wikipedia, common red clay could be found locally in most parts of the Roman Empire, making it widely accessible.

Higher quality clays for making fine pottery, such as white and orange clays, often came from specific locations. For example, orange terra-cotta clay was imported from Etruria in central Italy, while white clay came from Kaulonia in southern Italy .

According to Maria Milani the most common types of clay used by the Romans included red clay, gray clay, buff clay, and white clay. Red clay was used for general pottery making and was found in abundance near Rome. Gray clay was commonly used for amphorae production due to its strength. Buff clay created a yellowish surface when fired and was used for tiles and bricks. White clay was rarer but prized for its whiteness after firing.

Preparing the Clay

The Romans put great emphasis on properly preparing and purifying the clay before use in pottery making. They utilized several techniques to remove impurities and ensure the clay was optimized for throwing and molding.

To start, the Romans would dig clay from local sources, often near rivers where fine sediments had settled. According to the YouTube video How Did The Roman’s Make Pottery?, they would then leave the clay outdoors and expose it to the elements, allowing rain to wash away soluble salts and impurities.

Next, they would knead the clay and soak it in water to create a slurry, allowing denser particles and grit to sink to the bottom in a process called elutriation (Ceramic Arts Daily). The remaining clay suspended in the water would be drained off and settled out in settling tanks.

This labor-intensive process of soaking, kneading, and settling was repeated multiple times to fully purify the clay. The ceramic arts article notes this iterative process helped isolate the finest clay particles, creating high quality clay optimized for throwing and molding.

Wheel Throwing

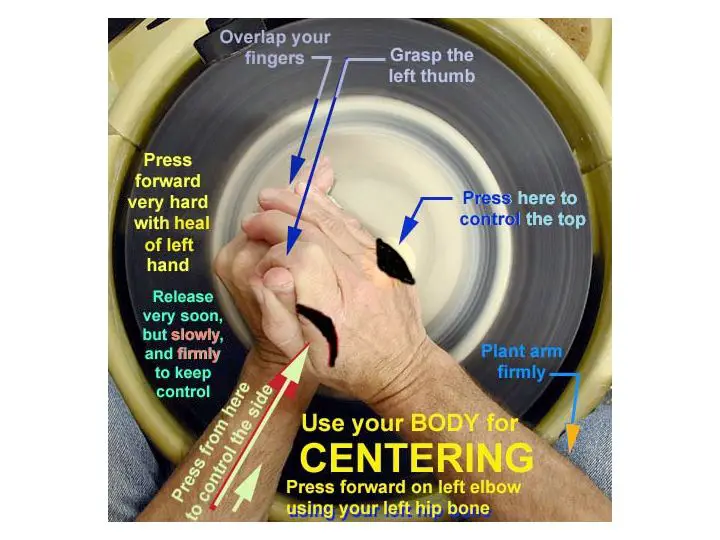

The potter’s wheel revolutionized how Romans made pottery and enabled them to mass produce ceramic vessels and amphorae. The wheel, which likely originated in Mesopotamia, appeared in Italy around the 7th century BCE. It consisted of a heavy circular platform that spun on a vertical axle (Wikipedia, 2023). The potter could rotate the wheel with their feet or an assistant turned it for them as they used their hands to shape the clay.

Wheel throwing required great skill to center the clay on the spinning wheel and manipulate it into the desired shape using a combination of downward pressure and gentle pulling. The potter would wedge and knead the clay to remove air bubbles before placing it on the wheel head. They would then shape the vessel by opening up the ball of clay, pulling up the walls to the desired height, and refining the rim and base. The potter could then refine decorative elements like fluting on column amphorae or add handles, spouts, or other appendages.

The potter’s wheel enabled the creation of symmetrical vessels with thinner walls compared to hand building. It greatly increased the speed at which pottery could be produced. However, it still required an experienced craftsperson to create fine wares. The Romans used the wheel to make utilitarian gray wares, amphorae, terra sigillata tableware, and other vessel forms that were essential for daily life and trade.

Molding and Casting

The Romans used molds to enable mass production of pottery. Molds allowed them to efficiently reproduce the same shapes and styles in large quantities. The two main casting techniques used were slip casting and press molding [1].

In slip casting, liquid clay is poured into porous plaster molds. The clay adheres to the surface of the mold creating a hollow cast after the excess liquid clay is poured out. This technique enabled detailed and intricate shapes to be replicated [2].

Press molding involved pressing soft clay into two-piece molds. The molds were often engraved with decoration that would be imprinted onto the clay. This allowed decorative patterns to be quickly reproduced.

Decoration

Romans used various techniques to decorate their pottery. Slips made of clay were commonly used to coat the surface and create a smooth, colored finish in hues like black, brown, red, and white. According to Ancient Roman Pottery | Rome Pottery – Maria Milani, the surface decoration of Roman pottery was more focused on relief work, colored slips, glazing, and other finishes.

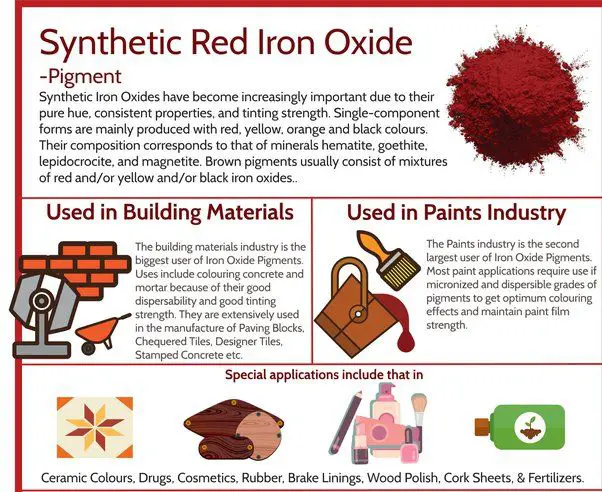

Painted decoration was also popular. Designs were painted on using mineral pigments like iron oxide for red and manganese oxide for black. Common painted motifs included flowers, animals, sea creatures, and mythological figures. Intricate geometric and floral patterns were prevalent as well. Painting was done on both the wheel-thrown fine wares as well as molded coarse pieces. According to the evolution of ceramic art, the Romans made extensive use of painted and molded decoration, though it limited the artistic heights their pottery could reach compared to Greek vessels.

Relief decoration was created by carving or pressing designs into the surface. Stamped patterns and rouletting were also used. Figurines and appliqué pieces like spouts or handles were attached. Once dry, pots were sometimes polished to create a glossy surface.

Drying and Firing

Before firing, Roman potters would allow their clay vessels to air dry slowly to avoid cracking. The vessels would be left to dry for several days or weeks depending on factors like size, shape, thickness, and humidity. Larger or thicker vessels required more drying time. Potters sometimes controlled the drying conditions by keeping vessels in a shaded area or covering them with damp cloths.

Once dried, the pottery was ready for firing in a kiln. The most common type of kiln used was the updraft kiln, which consisted of a firing chamber with a stokehole below and vents above. A wood fire was lit in the stokehole, heating the chamber from below. Temperatures could reach over 1000°C in the kiln, hardening the clay through vitrification and chemically altering the clay and pigments to set the color decorations. Firing typically took 6-48 hours depending on the size of the kiln and desired results.

Another kiln design was the clamp kiln, which involved stacking pots with fuel inside a temporary domed structure made of turf, clay, and straw. This was a simpler but less controllable method of firing. Excavations at archaeological sites have uncovered the remains of Roman kilns and firing waste, which provide insights into their pottery production.

(Source: https://peterborougharchaeology.org/the-roman-kiln/)

Common Vessel Types

The Romans created a wide variety of vessels that served practical purposes in daily life. Some of the most common types of Roman pottery include:

Amphorae – Large two-handled jars used to transport goods like wine, olive oil, fish sauce, and grains. They had a long, slim shape with a narrow neck and handles on both sides. Amphorae were often stamped or labeled to identify their contents and origin.

Jugs – Smaller vessels with a handle used for pouring and drinking liquids. Jugs came in various shapes like spherical, pear-shaped, and cylindrical. Some featured spouts for pouring and some had lids.

Bowls – Used for serving and eating food. Bowls came in many sizes and depths, from small dishes to large serving bowls. Some were plain and utilitarian while finer examples had decorative elements.

Mortaria – Mixing bowls with gritty interior surfaces used for food preparation. The rough interior helped grind ingredients. Mortaria often had pouring spouts and handles.

Plates/platters – Flat dishes used for serving food. These came in various depths and diameters, from small plates to large serving platters.

The variety of shapes allowed different vessels to serve distinct purposes related to storage, transportation, preparation, serving, and consumption of foods, liquids, and other goods.

(Source: http://llws-colchester.esdm.co.uk/LLFiles/1331/full_1331.pdf)

Trade and Distribution

Roman pottery was widely traded both locally and across the vast Roman Empire. Locally, pottery was sold at markets in towns and cities across the empire. Potters also had workshops attached to their kilns where they could sell their wares directly to customers.

For longer distance trade, pottery was loaded into amphorae, barrels, and crates and transported by carts, wagons, boats and ships across the Roman road and maritime trade networks. The extensive Roman road system helped move goods efficiently across land. Shipping routes spread Roman pottery across the Mediterranean Sea and beyond.

Archeological evidence shows that fine Italian pottery like Terra Sigillata and African Red Slip ware have been found all over the empire from Britain to Egypt to the Middle East. Transport amphorae carrying olive oil, wine, fish sauce and other goods were imported back full of Roman pottery. The volume of pottery traded indicates it was a valuable trade commodity for the Romans.

Analysis of pottery shards found at sites like ports and known Roman settlements demonstrates the significant scale of Roman pottery trade and distribution. Goods flowed all over the empire due to Roman peace, advanced transport infrastructure, and strong economic demand. Roman pottery has even been found as far as India, showing how far it reached along Mediterranean trade routes. (Looking from Arabia to India: Analysis of the Early Roman ‘India’ Trade in the Indian Ocean during the Late Pre-Islamic period (3rd century BC-6th century AD). https://www.academia.edu/9634344/Looking_from_Arabia_to_India_Analysis_of_the_Early_Roman_India_Trade_in_the_Indian_Ocean_during_the_Late_Pre_Islamic_period_3rd_century_BC_6th_century_AD_)

Legacy and Significance

Roman pottery had a major cultural impact across the vast Roman Empire and beyond. Pottery vessels, lamps, and figurines were traded over long distances and have been found as far away as India and Britain (Wikipedia). The mass production and widespread distribution of Roman pottery spread Roman cultural influence into remote regions.

Many examples of Roman pottery can be seen today in major museums around the world. Some of the finest examples are displayed at the British Museum in London, which houses one of the world’s largest collections of Roman pottery (British Museum). Other notable collections can be found at the Louvre in Paris, the Metropolitan Museum of Art in New York City, and the National Archaeological Museum in Athens.

The excellent preservation and abundance of Roman pottery provides valuable insights into daily life in ancient Rome. Pottery is an important tool for archaeologists studying Roman trade, culture, technology and society. The cultural legacy of Roman pottery continues to this day, as modern ceramicists still look to ancient Roman techniques and designs for inspiration (Springer).