How Do You Make Clay Pieces Stick Together?

Clay is a versatile material composed primarily of fine-grained minerals like kaolinite that can be molded when wet. Joining separate pieces of clay is an essential skill in ceramic arts and pottery. Properly joining clay components allows you to make more intricate and complex shapes. There are several techniques for combining clay pieces, all which rely on binding the clay particles together across the joint.

The goal when joining clay is to merge the pieces so the joint is strong and uniform with the rest of the form. Well-connected clay components should not separate or crack along the seams when firing or glazing. With practice and care, clay parts can be seamlessly fused together into beautiful ceramic artworks and vessels.

Prepare the Clay Surfaces

One of the most important steps in joining clay pieces is properly preparing the surfaces that will be connected. This provides the clay with texture so that the adhesive (whether slip, water, or glue) can grip between the two surfaces. Here are three key things to do:

Clean off dust/debris – Wipe the surface of the clay pieces with a damp sponge or cloth to remove any dried clay, dust or debris. This ensures the surfaces are clean for maximum adhesion.

Score or roughen surfaces – Use a serrated rib tool, knife or fork to scratch diagonal lines into the surfaces to be joined. This scoring gives the adhesive something to grab onto for a tighter hold. Score both pieces that will be connected.

Use slip – Brush on a thin layer of clay slip onto both scored surfaces. Clay slip is simply watered down clay that acts as an adhesive “glue”. The slip will fill the scratches and provide a tacky surface for the two pieces to stick to each other.

Using Slip

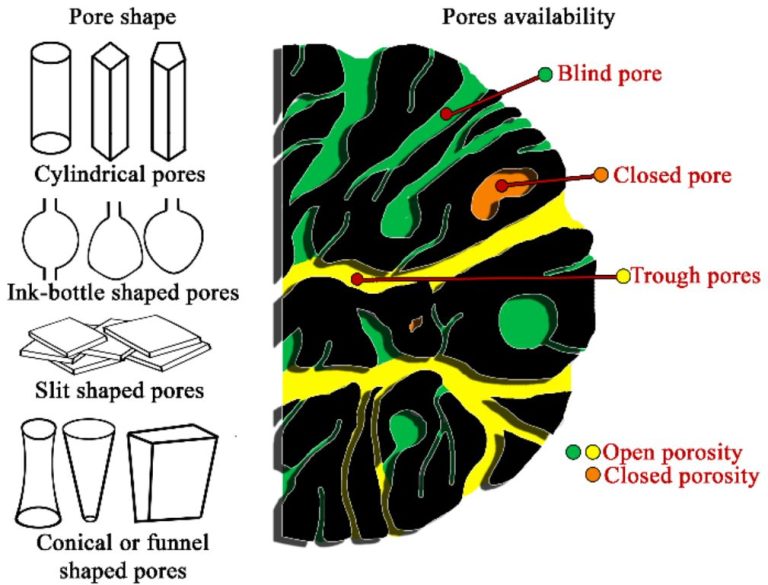

Slip is a liquid clay mixture used to help bond pieces of unfired clay. It acts as a glue by filling in any porous areas between pieces and hardening as it dries.

Definition of Slip

Slip consists of clay and water mixed into a liquid state. The clay particles in the water adhere to the rough clay surfaces they are applied to, forming a strong bond as the pieces dry and fire.

Making Your Own Slip

To make your own slip, start by mixing equal parts clay and water in a bucket or large container. Use a drill with a paint mixer attachment to blend it into a smooth, liquid consistency. Add water or clay as needed to achieve an even mixture that coats surfaces evenly without being too thick or runny.

Using Commercial Slip

There are also premade commercial slip products available for purchase from most ceramic suppliers. These come ready to apply without any mixing needed. Look for slip specifically formulated for the type of clay you are using.

Applying Slip

Before joining pieces, apply a thin layer of slip to any areas that will contact each other using a small brush or sponge. Scrub it into the clay surfaces to fill pores and ensure full coverage. Let the pieces dry until slightly leather hard before pressing them together firmly. The slip will dry and form a strong bond between the surfaces.

Scoring and Scratching

Scoring and scratching refers to creating roughened grooves or texture on the clay surfaces before joining them together. This helps the slip or water penetrate and creates a stronger bond between the pieces.

Definition: Scoring simply means scratching or etching the surface while the clay is still soft, usually in a cross-hatch pattern, using various tools. This roughs up the surface so there is more grip and traction for adjoining pieces to hold onto.

Tools for scoring: Pottery tools like ribs, loop tools, forked scrapers, craft knives, or even toothpicks can be used to score clay. Avoid using anything that might leave residues or contaminate the clay. The tool can be held at an angle and gently dragged across the surface to create scratches.

Depth and pattern: The scoring does not need to be deep, just enough to roughen up the surface, usually 1/16 to 1/8 inches. The pattern can be a straight grid or cross-hatch of lines, concentric circles, curvy meandering lines, etc. The main goal is to maximize surface area and roughness.

When to score: Scoring is done before applying slip or water to join fresh clay pieces together. It is especially useful for wet clay attachments that need to withstand pulling or gravity before firing. Scoring provides the grip and traction needed for a strong clay bond.

Using Water

One of the simplest methods for joining clay is to just wet the surfaces that you want to connect. When working with clay, water acts as a lubricant that allows the clay particles to move and conform to each other. By getting the clay surfaces wet before joining, you enable the clay to fuse together more tightly.

To wet join your clay:

- Use a spray bottle, brush, or sponge to moisten the surfaces you want to connect.

- Apply water until the surface has a shiny appearance.

- Press the wet surfaces together firmly to seal the joint.

Wet joining has some advantages over using slip:

- It’s faster, requiring fewer steps.

- There’s no drying time needed.

- It doesn’t require you to mix up slip.

On the downside, wet joining may not form as strong of a bond as using ceramic slip. The joint is dependent on the clay bodies themselves adhering together well. For large clay pieces or structural integrity, slip may be a better option.

Applying Pressure

Properly applying pressure when joining clay pieces is critical for creating strong bonds. There are several techniques you can use:

Pressing by Hand

Pressing clay surfaces together by hand allows you to ensure there are no gaps or air bubbles. Start by firmly pushing the clay pieces together, squeezing out any air between them. Use your fingers and palms to apply even pressure across the entire joint. Continue pressing for 30-60 seconds to help the clay merge together.

Using Tools

Tools like ribs, rollers, and wooden modeling tools can apply localized pressure to clay joints. Run the tools over the seam while pressing down to smooth and compress the clay. This helps meld the surfaces together. Apply pressure with tools for at least 30 seconds.

Clamps

Clamps are very effective for applying constant, even pressure across a joint as the clay dries. Small spring clamps or clothespins work well. Apply them across the seam and leave them on for at least a few hours as the clay dries. The sustained pressure helps bond the clay firmly.

Allowing Drying Time

After applying pressure, allow adequate time for the seam to dry before handling. Drying time depends on factors like clay type, size of pieces, and environment. Allow at least 15-30 minutes of drying time before moving joined pieces. The clay needs time to bond together under the applied pressure before being handled.

Adhesives and Glues

Types of ceramic adhesives

There are several types of adhesives that can be used to join clay pieces together:

- Water-based ceramic adhesives – These are white glues specially formulated for bonding clay. They dry clear and are easy to apply.

- Epoxy adhesives – Epoxy comes in two parts that must be mixed before use. It forms an incredibly strong bond.

- Cyanoacrylate glues – Also known as super glues, these set very quickly and work on non-porous materials.

When to use

Water-based ceramic adhesives are good for joining pieces like appliqués, handles, or spouts where some movement may occur during drying. Epoxy is ideal for joining unfired pieces that require a very strong bond. Cyanoacrylate glues are best for gluing fired pieces together where a fast-setting adhesive is needed.

Application tips

To properly adhere clay pieces, apply a thin, even layer of glue to both surfaces to be joined. Press the surfaces together firmly and hold for 30-60 seconds. Allow time to fully cure based on adhesive instructions before handling. Wipe away any excess glue squeezed out of joints before drying occurs. Avoid using too much glue, which can cause weak joints or longer drying times.

Sealing the Joint

Sealing the joint where two clay pieces meet is an important step to help pieces adhere and prevent breakage. There are a few main techniques for sealing clay joints:

Slip Trailing

Slip trailing involves brushing liquid clay slip along the joint to “trail” slip into any gaps in the joint. Slip helps fill air pockets and bonds the clay pieces. Use a small brush to apply a thin line of slip along the joint, letting it trail just slightly down the sides of the pieces.

Using Commercial Sealants

There are commercial sealants made specifically for sealing joints when working with clay. These liquids chemically bond the clay surfaces together. Brush a thin coat along the joint and let dry completely. Follow manufacturer instructions for best results.

Painting Joint with Slip

For a smooth finish, paint a thin layer of clay slip over the entire joint using a small brush. Smooth the slip out over the joint with the brush. Let the slip dry completely. This will create an imperceptible joint with a cohesive look.

Bisque Firing

Bisque firing is a crucial step when joining clay pieces together. Proper bisque firing helps strengthen and solidify the joints.

Firing Schedule

When bisque firing joined clay pieces, follow a slow ramp up to the peak temperature. This allows any moisture in the clay to evaporate slowly rather than turn to steam and risk cracking or blowing apart pieces. Increase the kiln temperature at a rate of no more than 200°F per hour. Allow the clay to soak at the peak temperature (usually cone 04 or 06) for at least 30 minutes.

Preventing Damage

Support pieces carefully on stilts or kiln posts so that weight is not placed directly on joints. Avoid bumping or jarring pieces when loading. Place extra kiln paper, fiber blanket, or soft bricks between pieces to prevent contact. Monitor temperature changes carefully.

Testing Strength

After bisque firing, check joints gently to ensure they have fused together properly. There should be no separation or cracking. Tap lightly to test for soundness. At this stage the bond will be strong but not fully vitrified.

Troubleshooting

Even when using proper clay joining techniques, your pieces may still experience issues like cracking or breaking apart. Here are some tips for troubleshooting common problems:

Cracking

Cracking often occurs because the clay dried out too quickly or unevenly. To prevent cracks:

– Wrap your piece in plastic wrap or put it in a plastic bag while working to slow drying.

– Avoid big differences in thickness in the piece which can lead to uneven drying.

– Let thicker areas dry adequately before joining to thinner areas.

– Score and scratch areas thoroughly before joining.

– Use slip generously.

– Allow slip to dry slightly before joining pieces.

– Avoid moving pieces before they are fully dry.

Breaking Apart

If pieces still break apart, there are a few likely culprits:

– The clay was not scored/scratched enough before joining. Always thoroughly score and overlap scratch marks for maximum adhesion.

– Too much water was used rather than slip. Water can weaken joints.

– The pieces were moved or stressed before fully dry. Leave joints undisturbed for at least 24 hours.

– Cooler thick parts were joined to warmer thin parts. Allow proper drying time to prevent moisture imbalances.

– Bisque firing temperature was too low. Fire to manufaturer’s recommended temps.

Preventing Future Issues

To avoid clay bonding problems on future projects:

– Knead clay adequately to remove air bubbles and uniformly mix ingredients.

– Use slip to join rather than water. Make sure slip soaks into scored areas.

– Allow sufficient drying time before handling pieces, especially larger ones.

– Bisque fire properly according to clay type before glazing.

– Glaze evenly and do not overload thick clay areas.

– Follow glaze firing guide to prevent glaze flaws.

– Let all pieces fully cool in the kiln after bisque and glaze firing before removing.