Is Scrapper A Hand Tool?

What is a Scraper?

A scraper is a versatile hand tool used for a variety of purposes involving scraping, cleaning, and shaping surfaces. Scrapers typically consist of a flat steel blade with a sharp edge fixed to a handle made of wood, plastic, or metal.

There are several main types of scrapers:

- Cabinet scrapers – Used for fine woodworking applications like smoothing wood surfaces.

- Paint scrapers – Used for removing paint, varnish, glue, and other materials from surfaces.

- Floor scrapers – Larger scrapers for removing floor finishes, adhesive, or debris.

- Roofing scrapers – Heavy-duty scrapers for removing shingles, tiles, coatings from roofs.

- Weld scrapers – Specialized scrapers for cleaning welds or removing welding byproducts.

Scrapers have many uses across construction, manufacturing, automotive work, arts and crafts, and home improvement:

- Smoothing and shaping wood

- Removing paints, varnishes, adhesives

- Cleaning surfaces like concrete, metal, tile

- Removing gaskets, dirt, rust from machinery

- Scraping welding seam areas

- Removing flooring materials or surface debris

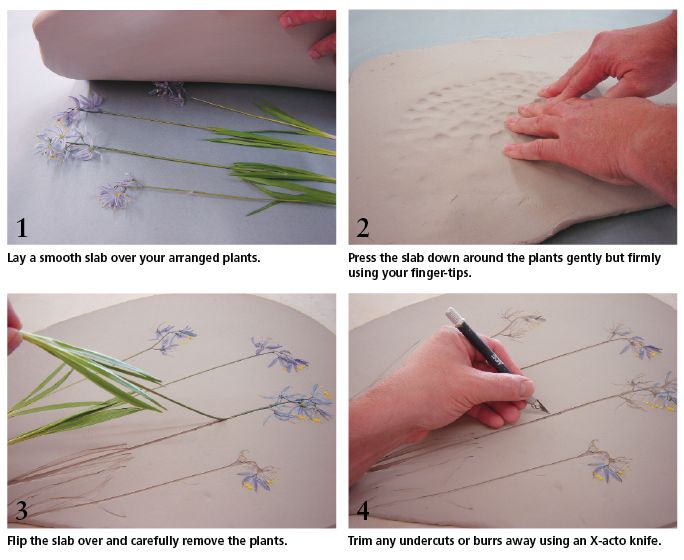

- Shaping and smoothing clay or sculpting materials

History of Scrapers

The origins of the scraper tool can be traced back to the Stone Age. Scrapers were an essential tool for early humans, used for preparing animal hides for clothing and shelter. According to the Encyclopedia Britannica, the first scrapers likely evolved from stone flakes, with one sharp edge that could be used to scrape hides [1]. These early prehistoric scrapers were made of materials like flint, chert, or obsidian.

Scrapers from the Paleolithic era were generally shaped flakes of stone, with one unretouched sharp edge. Common types were end scrapers, side scrapers, and thumbnail scrapers. As scraper designs evolved, tool makers began intentionally shaping the stones to create more efficient scraping tools. By the late Stone Age, scrapers took on more standardized and specialized shapes like the so-called “turtleback” scraper [2].

Over time, scraper designs continued improving as metalworking allowed scrapers to be made from materials like copper, bronze, and eventually iron and steel. In the modern era, scrapers have evolved into a diverse array of specialized hand tools made from metal alloys and other synthetic materials.

Scraper Design and Parts

Scrapers have two main components: the handle and the blade. The handle is generally made of wood, plastic, or metal and allows the user to grip and apply force when scraping. The blade is typically made of high carbon steel for strength and durability. Common design elements of scrapers include:

The blade comes in various shapes and angles depending on the scraping task. Common blade shapes include rectangular, curved, triangular, and hooked. A rectangular blade with sharp 90 degree corners works well for scraping flat surfaces. A curved blade conforms better to contoured surfaces. Triangular blades allow accessing corners and tight spaces. Hooked blades are useful for scraping grout lines and detailed areas (source).

The handle on most scrapers is made of hardwood, plastic, or metal. Wood handles provide a comfortable grip but can break over time. Plastic is durable and shock-absorbent but can feel slippery when wet. Metal handles are extremely strong but transmit more vibration during use (source). The handle shape and length varies based on the scraping application.

Using Scrapers

Proper technique is important when using a scraper tool to achieve the desired results. Applying the right amount of pressure at the proper angle while pulling the scraper is key. As noted in https://vocal.media/lifehack/how-price-scraping-benefits-sellers, “Below are some of the tips on how to use a scraper tool. 1. Competition. Whether the seller is small or most selling, one always needs a strong understanding of the market.” Understanding how to use a scraper takes practice and experience.

When scraping, it’s important to apply firm, even pressure on the tool without being overly forceful. Maintaining a consistent angle of about 45 degrees helps remove material efficiently as you pull the scraper across the workpiece. As https://www.hwoodturners.org/tutors-tidings/ewExternalFiles/TT%2021%20scrapers.pdf explains, “After you have gripped the scraper, extend your index finger to point toward the end of the tool. Pointing the finger helps maintain the proper angle.” Let the sharpened edge do the work rather than applying brute force.

Scrapers will gradually lose their keen edge with use. Honing and sharpening them regularly helps restore performance. A finely sharpened edge helps produce smooth, clean results. Specialized sharpening equipment like a grinder fitted with a sharpening jig can be used. Or hand sharpening using diamond stones or wetstones to polish a keen edge. Proper scraper care and maintenance leads to better results.

Types of Scrapers

There are several common types of scraper tools used for various purposes:

Cabinet scrapers are rectangular pieces of steel with a beveled edge used to smooth wood surfaces. The beveled edge allows you to scrape off very thin shavings of wood for a smooth finish.

Card scrapers are small handheld scrapers with a curved blade used to scrape paint or varnish from surfaces. The flexibility of the steel allows the edge to curl as you scrape, cutting through coatings more aggressively than a flat scraper.

Paint scrapers are flat, stiff blades with a sharp 90-degree edge used for scraping paint and wallpaper. They come in a variety of widths from 1 to 6 inches.

There are also specialty scraper tools designed for specific uses like foam scrapers for removing foam insulation, or gear scrapers used to clean the teeth of gears in machinery.

Scraper Uses

Scrapers have many handy uses around the home and workshop. Some of the most common uses for scrapers include:

- Removing paint and varnish – Scrapers are effective at removing old paint and varnish from wood surfaces in preparation for refinishing. The thin, rigid blade can get under layers of paint to scrape it off smoothly (1).

- Smoothing wood surfaces – Scrapers can be used to remove bumps, marks, or defects from wood before finishing or painting. The scraper smoothes the surface and evens out any imperfections (1).

- Cleaning glass and tiles – A scraper with a sharp blade edge can scrape off scale, mineral deposits, soap scum, and grime from glass shower doors, bathroom and kitchen tiles, and other hard surfaces. Scrapers are useful for cleaning in corners or crevices (2).

With the right type of scraper, technique, and a little elbow grease, scrapers can simplify many cleaning and surface preparation tasks around the home.

(1) https://www.easternplanthire.com/2020/08/06/uses-for-scrapers/

(2) https://www.apexinds.com/blog/use-scrapers.html

Scraper Safety

When using scrapers, it’s important to take proper safety precautions to avoid injury. Here are some tips for staying safe:

Hand Protection – Wear thick work gloves when scraping to protect your hands and fingers from the sharp blade. Gloves will prevent cuts and scrapes if the blade slips.

Sharp Blade – Always use a sharp blade and replace dull blades promptly. A sharp blade requires less pressure and is less likely to slip and cause accidents. Dull blades can catch and jerk out of control.

Proper Storage – When not in use, store scrapers in a sheath or blade cover. Don’t leave loose blades lying around. Place in drawers or cabinets safely out of reach of children.

Focus – Stay focused on the task at hand. Don’t let your blade scrape across your fingers or hands. Pay close attention to blade angle and pressure.

Safety First – Rushing through a scraping job can lead to mistakes and injury. Work slowly and carefully. It’s better to take longer than have an accident. If ever in doubt, stop and consult scraper safety guidelines.

By wearing gloves, keeping blades sharp, storing safely, staying focused, and putting safety first, scrapers can be used responsibly with minimal risk of harm.

Scrapers vs. Other Tools

Scrapers have some key differences compared to other common woodworking hand tools like chisels, planes, and sandpaper. Here is how scrapers stand out:

Chisels – Chisels cut into the wood by striking the back of the blade. Scrapers only remove material from the surface. Chisels require sharpening at an angle while scrapers sharpen to a burr. Chisels can dig deeper but scrapers excel at fine surface smoothing.

Planes – Hand planes use angled blades to slice off shavings. Scrapers rub across the surface to shear off just a thin layer. Planes are ideal for major stock removal and flattening while scrapers refine the surface.

Sandpaper – Sanding abrades the wood fibers to smooth and shape. Scraping slices off fibers cleanly. Sandpaper leaves microscopic scratches while scraping can produce a glass-smooth surface. Scrapers are efficient at removing flaws between sanding grits.

Scrapers become useful when you need to finely smooth wood without digging in like a chisel or plane. They excel at dealing with difficult grain patterns and working into tight spaces. Scrapers produce an exceptionally smooth surface and efficiently remove defects prior to the final sanding grit.

Purchasing Scrapers

When purchasing a scraper, there are a few key things to look for:

The blade material is important – high carbon steel holds an edge better than stainless steel but can rust if not cared for. Carbide blades are very durable but brittle. For home use, high carbon or stainless steel are good options.

Look for a comfortable, ergonomic grip to reduce hand fatigue during scraping. Plastic, rubber, and wood handles provide grip.

Scrapers come in various sizes, from small detail scrapers to large floor scrapers over 12 inches. Consider your project size when choosing.

Quality brands like Bahco, Stanley, and Hyde are known for good steel and design but cost more. Cheaper scrapers may need more sharpening and replacement.

Maintenance involves cleaning off any residue after use, drying thoroughly, and applying a light oil to prevent rusting. Sharpen the blade as needed to keep a keen edge.

Conclusion

Scrapers are versatile and useful hand tools that have been around for centuries. They are designed with a flat blade to scrape surfaces by removing dirt, grime, paint or other materials. Scrapers come in many types like cabinet scrapers, paint scrapers, floor scrapers and more, each suited to specific jobs. They allow for precise work in scraping smooth surfaces. Scrapers are an essential addition to any toolbox.

When using scrapers, it’s important to follow safety precautions. Wear gloves and eye protection. Make sure to scrape away from your body. Choose the right type of scraper for the material you need to remove. With proper use, scrapers can save time and effort on projects.

In summary, scrapers are handy, inexpensive tools that have stood the test of time. Their simple yet effective design makes them indispensable for scraping, cleaning and surface preparation tasks. Scrapers remain a useful and versatile hand tool for DIYers, crafters, artists, construction workers and many other trades.