What Is 9 Gauge Wire Used For?

Wire gauge refers to the diameter or thickness of wire. The gauge measurement system originated in Britain and is widely used in the United States. Wire diameter decreases as the gauge number increases; a larger gauge number indicates a thinner wire. 9 gauge wire has a diameter of 0.162 inches (4.11 mm) (1).

9 gauge wire is a fairly thick, stiff wire used in a variety of applications. It is thicker and stronger than smaller gauges like 12 or 14 gauge wire, but more flexible than very thick gauges like 6 gauge. Some key uses and applications of 9 gauge wire include (1,2,3):

- Household wiring

- Automotive/marine wiring

- Industrial wiring

- Electrical grounding

- Commercial building wiring

The thickness and durability of 9 gauge wire makes it well-suited for applications that require a heavier-duty wire. It can safely conduct higher amp loads than smaller wires. The stiffness of 9 gauge also makes it easy to work with for structural applications like fencing. Some drawbacks are that it may be overkill for household circuits and more expensive than thinner gauges (4). Overall, 9 gauge hits a nice balance between ampacity, durability, and flexibility.

(1) https://redbrandstore.com/products/galvanized-smooth-wire-9-gauge-1701

(2) https://www.signetfence.com/9-gauge-galvanized-utility-wire-for-chain-link-fencing-1000-roll/

(3) https://www.homedepot.com/p/FARMGARD-170-ft-9-Gauge-Galvanized-Steel-Coil-Smooth-Wire-317527A/206741174

(4) https://www.thespruce.com/wire-gauges-1152865

Wire Gauge Measurement

The measurement of the thickness of wire dates back to the 19th century. One of the earliest wire measurement standards was the Stubs Iron Wire Gauge established in Britain in 1883. This was superseded by the British Standard Wire Gauge (SWG) which was formulated in Britain in 1884. The SWG related the wire size to the number of draws through a die to produce the desired diameter. The American Wire Gauge (AWG) was developed in 1857 and is based on the circumference of the wire rather than the number of draws [1].

Today there are several standards for wire gauge measurement used around the world. The most common is the American Wire Gauge (AWG) which utilizes a numerical system to specify wire diameters, the higher the number indicating the smaller the wire diameter. For example, 50 gauge wire has a smaller diameter than 12 gauge wire. The AWG system is a logarithmic scale relating wire diameter to amperage capacity. As the gauge number increases, the diameter decreases mathematically by dividing by 92 for every 3 steps. The AWG system is used predominantly in North America [2].

Other common wire gauge standards include the Standard Wire Gauge (SWG) used in Britain and Europe, the Stubs Iron Wire Gauge, and the Steel Music Wire Gauge for piano wire. The diameter of a wire gauge can be determined by consulting a wire gauge chart specific to the particular standard being used.

9 Gauge Wire Properties

9 gauge wire is comprised of solid copper, making it an excellent conductor of electricity. According to the Wire Gauge Chart from Alabamawire.com, 9 gauge copper wire has a diameter of 0.148 inches and weighs approximately 31.208 lbs per 1,000 feet [1]. The Standard Wire Gauge Conversions table from Pyromation indicates 9 gauge wire has a diameter of 0.1495 inches [2].

In terms of resistance, 9 gauge copper wire has a resistance of approximately 0.727 ohms per 1,000 ft. This lower resistance allows 9 gauge wire to carry more current than smaller gauges over the same distance with less voltage drop. Insulation material can vary, with common options being PVC, THHN, THWN, and XHHW.

The diameter, weight, and resistance specifications make 9 gauge an excellent choice for applications requiring high current capacity and power transmission with minimal voltage drop.

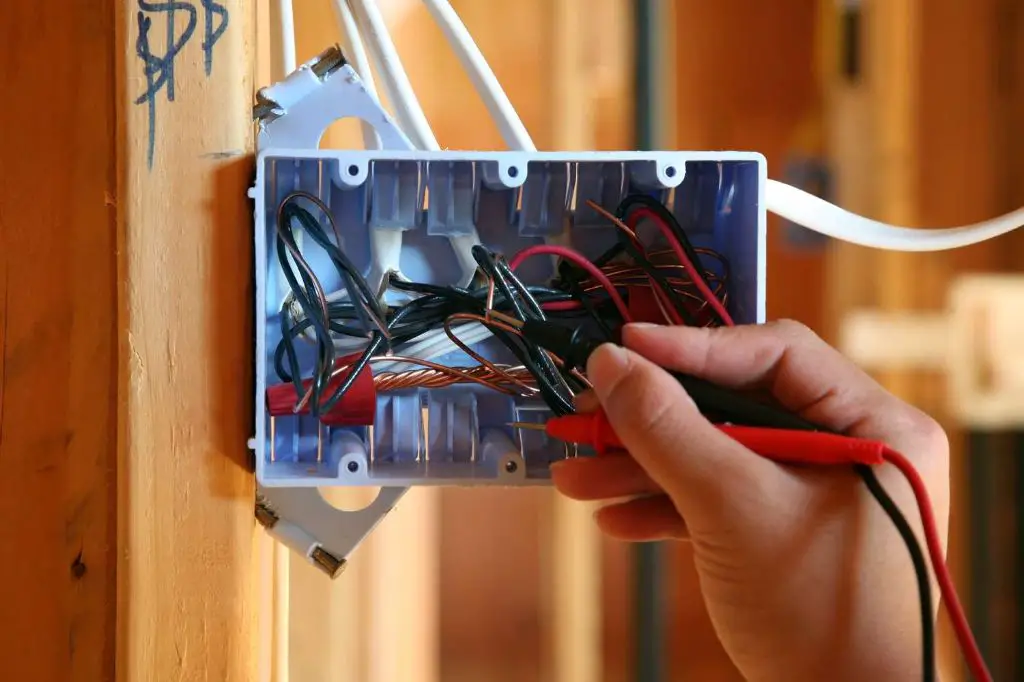

Uses in Household Wiring

9 gauge wire is commonly used for household electrical wiring applications, especially for high power devices and appliances. According to The Home Depot, 9 gauge wire has a 165 pound safe working load and is used for a variety of household wiring jobs (source). The larger size and current capacity of 9 gauge makes it well suited for wiring lighting circuits, outlets, major appliances, electric dryers, room air conditioners, and sump pumps.

For lighting, 9 gauge can be used to wire multiple fixtures on one circuit while avoiding voltage drop over long wire runs. It is also recommended for hardwired electrical outlets and receptacles that need to supply high amp appliances like refrigerators, freezers, or window AC units. The Family Handyman recommends 9 gauge for most major kitchen and laundry appliances like electric ranges/ovens, dishwashers, microwaves, and clothes dryers that require 30-50 amp circuits (source).

For home systems, 9 gauge is commonly used for wiring sump pumps, HVAC condensing units, and other high power motors. It provides the ampacity for these systems to start up and run properly. Overall, 9 gauge offers capacity above standard 14/12 gauge wire for demanding household circuits.

Uses in Automotive/Marine

9 gauge wire is commonly used for power applications in automotive and marine settings. Its increased thickness allows it to safely handle the high current draw from components like starters, alternators, and winches without overheating.

In cars, trucks, and boats, 9 gauge wire is well suited for the main power feed from the battery to high current components like the starter motor. The high torque needed to turn over an engine requires thick wire to avoid excessive voltage drop. According to this marine wiring guide, 9 gauge is rated for up to 55 amps, making it a good choice for powering a typical automotive starter that draws 35-150 amps during cranking.

For alternators, which output high amounts of current to charge the battery, 9 gauge is commonly used for the main output wire. Under heavy electrical load it allows the high alternator output current of around 100 amps in cars to flow with minimal resistance and voltage drop.

In boats, 9 gauge is excellent for wiring trolling motors, electric winches, and other moderately high powered electric marine accessories. The thick insulation and conductor allow it to stand up to vibration and flexing stress. According to this marine cable supplier, 9 gauge is rated to carry 87 amps continuously – sufficient for most trolling motors and deck gear.

Uses in Electronics

9 gauge wire is commonly used for wiring electrical components in hobby electronics, guitars amps, and PA systems where a thicker gauge is needed to handle higher amp loads (PRC Silicone Wire). The thicker 9 gauge wire is well-suited for these applications because it provides less resistance and allows more current to flow through the wire without overheating.

For hobby electronics projects like robots, quadcopters, and R/C vehicles, 9 gauge wire can be used to connect the battery to high-draw components like motors and speed controllers. The lower resistance minimizes power loss over longer cable runs from the battery to the electronics (Amazon).

In electric guitar amplifiers and PA systems, 9 gauge speaker cable is commonly used to connect the amplifier to the speakers. It allows the amplifier to provide full rated wattage to the speakers without power loss or heat buildup in the cables. High-end audio systems benefit from the improved power transfer and reduced signal loss.

Industrial Applications

9 gauge wire is commonly used for industrial equipment and machinery where thick, durable cabling is required. Some key uses in industrial settings include:

- Motors – 9 gauge wire can be used to connect large industrial motors that draw significant current. The thick gauge helps reduce voltage drop over long cable runs.

- Controls – For connecting industrial control panels and PLCs (programmable logic controllers). 9 gauge can handle high currents for operating motors, valves, and other equipment.

- Welding – 9 gauge cable is well-suited for welding equipment due to its high current capacity. It’s used for connecting welding power sources to machines.

- Hoists & Cranes – Hoist motors often require thick 9 gauge supply cables for power and control. Crane festoon systems also frequently use 9 gauge cabling.

- Machine Wiring – Inside industrial machinery, 9 gauge is used for high current components like drive motors, heaters, pumps etc. Its durability handles vibration.

Industrial facilities rely on 9 gauge wire for numerous heavy-duty applications where machinery requires power, control, and data connectivity. Its high ampacity and durability make it an essential cable size for manufacturing, processing, and fabrication industries.

Sources:

https://www.trusupply.com/Tie-Wire-Roll-9-Gauge-Black-Annealed-100lb.html

https://generalworkproducts.com/shop/tie-wire/100-lb-9-gauge/

Commercial Building Wiring

The 9-gauge wire is commonly used for electrical wiring in commercial buildings like offices, retail stores, warehouses, etc. It can safely carry higher amperages needed to power the lighting, outlets, appliances, HVAC systems, and other electrical loads in these buildings Amazon.

For lighting circuits in office buildings and retail stores, 9-gauge wire allows more fixtures to be wired on each circuit while following electrical code requirements. The higher ampacity handles the total wattage load. In large open warehouse spaces, the 9-gauge wire runs can be very long to reach all the lights so the thicker gauge handles voltage drop over the distance Trusupply.

Important safety systems like fire alarms, emergency lighting, and security systems often utilize 9-gauge or even thicker wire. This ensures critical circuits have ample capacity and redundancy. The 9-gauge can also be used for wiring between electrical panels and subpanels in commercial buildings when required by electrical load calculations.

Comparison to Other Gauges

When choosing a wire gauge for a project, it’s helpful to compare 9 gauge to other common gauges like 10 gauge and 8 gauge to understand the key differences.

Compared to the slightly thinner 10 gauge wire, 9 gauge is able to carry more current – around 30 amps versus 40 amps. This makes 9 gauge a better choice than 10 gauge for high current applications like power transmission over longer distances, where voltage drop becomes a concern. The tradeoff is that 9 gauge is less flexible and costs more per foot than 10 gauge.

Moving up to thicker 8 gauge wire, it’s rated for even higher current capacity around 50 amps. However, it is stiffer and more expensive than 9 gauge. So 8 gauge may provide more headroom for extremely high current uses, but is harder to work with. When flexibility and cost are a priority, 9 gauge offers a good middle ground.

Overall, 9 gauge hits a nice balance between capacity, flexibility and cost that makes it preferable for many common applications than jumping up or down a size.

Conclusion

In summary, 9 gauge wire has a wide variety of common uses due to its versatility and durability. It is frequently used for household wiring of major appliances, automotive/marine applications requiring a thicker gauge, certain electronics where more power transmission is needed, industrial equipment wiring, and commercial building wiring for lighting, motors, and HVAC systems.

You’ll want to choose 9 gauge wire when you need more current capacity and less voltage drop compared to smaller gauges. It offers a good balance of thickness and flexibility. Some examples are wiring a subwoofer audio system in your car, connecting high powered tools or machinery, or wiring high voltage lighting circuits.

Looking ahead, we may see 9 gauge used more prevalently as energy demands continue to rise in residential and commercial settings. With more high powered electronics in homes and EVs becoming mainstream, the applications for 9 gauge wire will likely expand even further.