What Is A Type K Thermocouple?

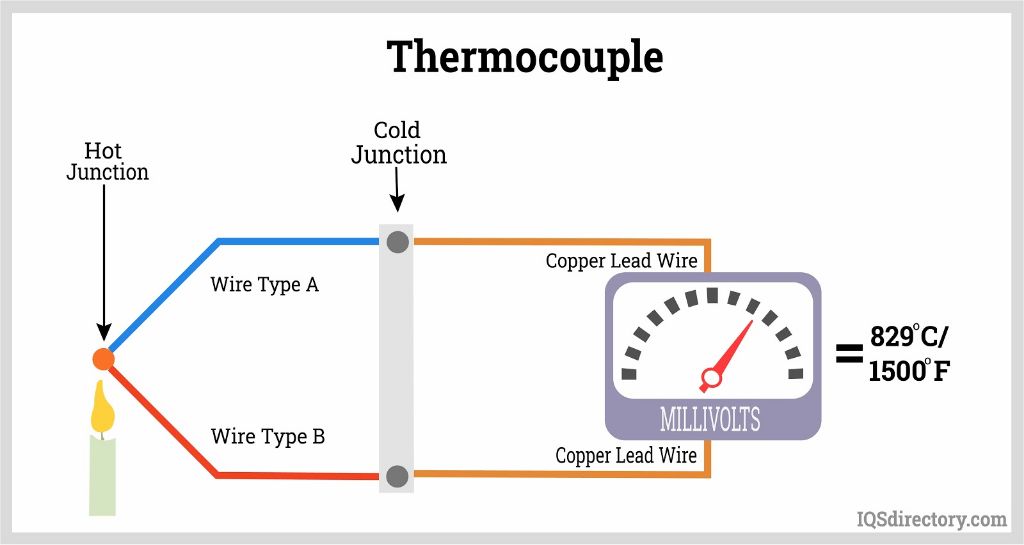

A thermocouple is a device used to measure temperature consisting of two dissimilar metal wires joined together at one end. A temperature difference between the junctions produces a small voltage that can be correlated back to the temperature. Type K thermocouples specifically refer to thermocouples made up of a Chromel (nickel-chromium alloy) positive wire and an Alumel (nickel-aluminum alloy) negative wire (Omega, 2022).

Type K thermocouples are inexpensive, versatile, and one of the most common general purpose thermocouples. They are capable of measuring a wide temperature range from -270°C to 1372°C (-454°F to 2,501°F) with temperature sensitivity of approximately 41 μV/°C.

Composition

The Type K thermocouple is composed of two different metals – chromel and alumel. The positive leg is made of chromel, which is an alloy of 90% nickel and 10% chromium. The negative leg is made of alumel, which is an alloy of 95% nickel, 2% aluminum, 2% manganese, and 1% silicon 1.

Chromel has a positive Seebeck coefficient, meaning it generates electricity when heated. Alumel has a negative Seebeck coefficient. When the two legs are joined at the sensing tip and heated, the difference in Seebeck coefficients generates a voltage that can be measured. The specific alloys used in Type K thermocouples enable accurate temperature measurements over a wide range.

Temperature Range

One of the key specifications of Type K thermocouples is their wide temperature measurement range. Type K thermocouples can measure temperatures from -270°C to 1372°C (-454°F to 2500°F) [1]. This makes them suitable for measuring very low cryogenic temperatures as well as extremely high temperatures inside furnaces, engines, and other hot processes.

Specifically, Type K thermocouples have a continuous temperature range from 0°C to +1100°C (+32°F to +2012°F). They can also withstand short term exposure to temperatures from -180°C to +1300°C (-292°F to +2372°F) [1]. This wide temperature range, both continuous and short-term, makes Type K one of the most versatile thermocouple types for general temperature measurement and control applications.

Accuracy

Type K thermocouples generally have an accuracy of ±2.2°C or 0.75% (whichever is greater) as per ITS-90 standards. This means they can reliably measure temperatures within this error range of the true temperature. For example, at 300°C the accuracy is ±2.9°C (from 297.1°C to 302.9°C). At 1000°C, the accuracy is ±7.5°C (from 992.5°C to 1007.5°C) [1].

The accuracy varies depending on the temperature range. At lower temperatures below 0°C, the accuracy is lower at ±2.5°C. Between 0-1200°C, the accuracy follows the ±2.2°C or 0.75% specification. Above 1200°C, the accuracy degrades and can be ±4.0°C or more at very high temperatures [2].

Accuracy can be improved through proper calibration. Using the standard calibration tables for Type K thermocouples, the voltage measurements can be converted to temperatures with minimal error [3]. However, thermocouple drift over time can reduce accuracy if not properly calibrated.

Overall, Type K thermocouples offer reasonably good accuracy for most general temperature measurement applications. More precise measurements would require using higher accuracy thermocouples or RTDs.

Advantages

The main advantages of Type K thermocouples are that they are inexpensive and have a wide temperature range. Type K thermocouples utilize inexpensive nickel-chromium and nickel-aluminum metals, making them one of the most cost-effective thermocouple options (Green Rot Physical). The combination of metals gives Type K thermocouples the ability to measure temperatures from -270°C to 1260°C, making them versatile for applications ranging from cryogenics to high-temperature industrial processes (RTD China Network). Their low cost and broad range make Type K thermocouples a popular general-purpose temperature measurement choice.

Disadvantages

While type K thermocouples are versatile, they do come with some downsides. Perhaps the biggest issue is that K type thermocouples are not the most accurate variant available. For high precision applications, other types like E, J, T or N thermocouples may be preferable as they provide higher accuracy in certain temperature ranges [1].

Another limitation is that type K sensors are prone to oxidation at very high temperatures. The chromel wire can oxidise in air above 500°C, which impacts the emf output and reduces accuracy over time. For oxidizing or reducing atmospheres above 500°C, other noble metal thermocouples like types B, R or S are more suitable [2].

Applications

Type K thermocouples are commonly used in a variety of applications due to their wide temperature range, accuracy, and durability. Some of the most common applications include:

HVAC – Type K thermocouples are widely used in heating, ventilation, and air conditioning (HVAC) systems to measure air and gas temperatures. They are used in thermostats, furnaces, heat pumps, boilers, and ventilation ducts to provide temperature feedback and control.1

Appliances – Appliances like ovens, clothes dryers, and refrigerators use Type K thermocouples to regulate temperatures and prevent overheating. They provide temperature measurement and control for baking, drying, and refrigeration.2

Industrial processes – The high temperature capabilities make Type K thermocouples suitable for monitoring and control in many industrial processes like metal processing, glass manufacturing, and chemical production. They can withstand harsh environments.1

Standards

The Type K thermocouple meets several industry standards for accuracy and reliability including IEC 60584, ASTM E230, and ANSI MC96.1. The IEC 60584 standard specifies materials, tolerances, and electromotive force tables for different types of thermocouples including Type K [1]. ASTM E230 similarly provides standard specifications for thermocouple materials while ANSI MC96.1 gives requirements for the color coding and polarity of thermocouple wires [2]. By meeting these standards, the Type K thermocouple provides known accuracy and repeatability according to globally recognized norms.

[1] https://tejase-aerosense.com/temperature/

[2] https://www.globalspec.com/industrial-directory/pcb_mount_thermocouple_connectors

Wiring and Connections

Type K thermocouples use color coding to identify the positive and negative wires. The positive wire is yellow, and the negative wire is red. This color coding allows for proper connections to be made to thermocouple instruments or extension wires.

When splicing or extending thermocouple wires, it is critical to maintain polarity by connecting the same colors together. Thermocouple extension wire or splice connectors with the same Type K yellow/red color coding should be used.

Some common connectors used with Type K thermocouples include miniature thermocouple connectors, screw terminal connectors, and thermocouple plugs. Mini connectors allow a thermocouple to be disconnected from a device. Screw terminals provide a secure connection. Thermocouple plugs allow for a quick connection and are commonly used with thermocouple extension wire.

Proper wiring and splicing is essential for Type K thermocouples to maintain accuracy. The color codes and proper connectors help avoid introducing errors through incorrect polarity.

Alternatives

While Type K thermocouples are very common, there are several alternatives that may be better suited for certain applications:

Type J thermocouples are made from iron and constantan and have a range of -210 to 1200°C. They have a similar temperature range to Type K but are less expensive. However, Type J is less stable at high temperatures. [1]

Type T thermocouples use copper and constantan wires. They have a range of -270 to 400°C, making them suitable for cryogenic applications. Type T has better accuracy than Type K at lower temperatures. [2]

Type E thermocouples made from chromel and constantan offer improved accuracy and stability at high temperatures up to 900°C. However, they have a more limited low temperature range of -270 to 1000°C. [3]

In summary, for specialized applications Type J, T or E thermocouples may be better choices than the commonly used Type K.