What Is The History Of Ceramics?

Ceramics are inorganic, non-metallic materials that are heated to high temperatures and cooled to produce materials with desirable properties like hardness, durability, chemical resistance, and low conductivity. Ceramics have played an important role in human civilization and technology since the earliest days of human history.

The history of ceramics is long and diverse, stretching back over 12,000 years as humans discovered natural clays and learned to shape and fire them into useful products. From prehistoric pottery and brick making to advanced ceramics used in modern electronics, aerospace, medicine, and more, ceramics have enabled the creation of art, tools, shelters, technologies, and infrastructure critical to the advancement of cultures worldwide.

This article will provide an overview of the history and evolution of ceramic materials, processes, and applications from ancient times to the present day. It will cover key eras, innovations, uses across human civilization, and the continuing importance of ceramics today.

Origins

The origins of ceramics date back over 30,000 years. Some of the earliest ceramic artifacts include Venus figurines and early pottery discovered across ancient civilizations. The Venus of Dolní Věstonice, found in the Czech Republic, dates back 29,000-25,000 BCE and is the oldest known ceramic in the world. Early pottery vessels have been found in East Asia dating back 20,000 years to the Jōmon people of Japan during the Upper Paleolithic period https://www.davisart.com/blogs/curators-corner/oldest-ceramic-vessels-japan-jomon/. Other early pottery developed in the Neolithic period across ancient China, Mesopotamia, and South America around 10,000 BCE as civilizations began using fired clay vessels for cooking and storage.

The development of early ceramics seems to have arisen independently across different ancient civilizations. Pottery and ceramic figurines appeared in East Asia, the Near East, and Mesoamerica at different points in history with no evidence of transmission between these regions.

Ancient Ceramics

Ceramics became an important material in many ancient civilizations. In ancient Egypt, pottery was made from clay and fired as early as 6000 BCE. Glazed ceramics were invented during the New Kingdom period and were used for funerary objects, tiles, and small sculptures (Brief history of ceramics). Ancient Greek pottery, such as the famous black-figure and red-figure styles, was produced between the 7th and 4th centuries BCE. Greek ceramics were often painted with scenes from mythology and served both utilitarian and artistic functions (Ceramic history).

In ancient Rome, pottery was mass-produced in factories and reached a very high level of technical skill. Roman potters developed specialized techniques such as terra sigillata, a glossy red slipware with relief decoration. Chinese ceramics also have a long history stretching back to 16,000 BCE. High-fired ceramics were produced during the Han dynasty and glazed ceramics became popular during the Tang dynasty. Chinese ceramics significantly influenced ceramic crafts in Korea and Japan (Ceramic).

Medieval Ceramics

Medieval pottery saw significant developments, especially with the rise of Islamic culture and trade routes during the Middle Ages. Islamic potters were known for their advanced techniques in materials and glazes. According to Joannturner.ca, “Muslims were forbidden to use metal plates and bowls. In the Middle East, Spain and North Africa, pottery was developed into a fine art, and was highly prized.”

Maiolica, a type of tin-glazed pottery from Italy, became popular in the Renaissance period. Horshammuseum.org explains that maiolica was “decorated in bright colours on a white background.” Maiolica was traded extensively and influenced pottery styles across Europe.

The development of true porcelain also began in the medieval period. Porcelain’s refined white body and translucent qualities made it a prestigious material. As trade expanded to Asia, medieval potters tried to reproduce the fine porcelain wares coming from China and regions like the Middle East.

Renaissance to 18th Century

In the Renaissance period, ceramics saw significant advances, especially in Italy with the rise of maiolica, a tin-glazed earthenware. Italian potters developed refined techniques for creating these lustrous wares, often with intricate painted decoration inspired by Islamic traditions. Major maiolica production centers emerged in Faenza, Deruta, and Gubbio. Renaissance maiolica reached its peak in the late 15th and early 16th centuries, with sought-after pieces like those from the workshop of Maestro Giorgio Andreoli.

By the 17th century, Delftware from the Netherlands became influential across Europe[1]. Crafted in the city of Delft, these blue and white tin-glazed earthenwares imitated Chinese porcelain styles. Intricate decoration depicted scenes from daily life. Delftware’s success encouraged other European pottery centers to imitate Asian styles and production techniques.

In 18th century England, Josiah Wedgwood pioneered new refinements in industrial ceramic manufacturing. He introduced improved pottery wheels, glaze recipes, and firing methods. Wedgwood’s factories produced fine tableware and ornamental vases in classical styles, as well as innovative ceramic bodies like jasperware and basalt. His perfection of English porcelain manufacture brought ceramics to a new level of commercial and artistic success.[2]

19th Century

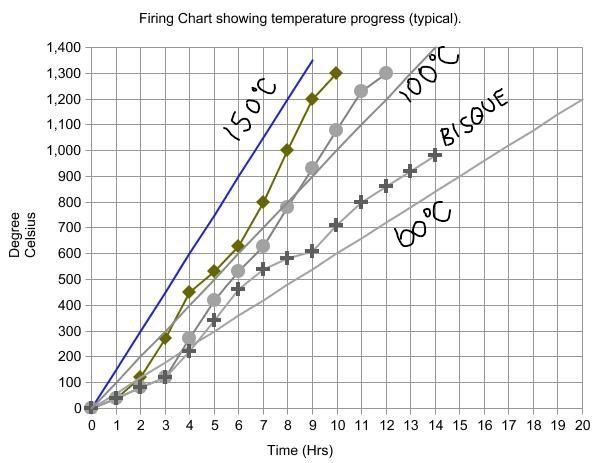

The 19th century saw major innovations in ceramic production and design due to industrialization. New kiln technologies such as the bottle kiln, tunnel kiln, and continuous kiln allowed for higher firing temperatures and continuous firing cycles, enabling mass production. Kilns could now reach over 1300°C compared to around 1000°C for older updraft kilns.

Important pioneers in 19th century English ceramics were Josiah Spode and his son Josiah Spode II who industrialized the production of high quality bone china. The formula for fine bone china was perfected by Josiah Spode around 1800, allowing translucent and delicate but durable wares. The Spode factory pioneered transfer printing and perfected underglaze blue printing. Other key English ceramic factories of the era included Wedgwood, Minton, and Royal Doulton.

In France, porcelain production was industrialized at factories like Limoges. In Germany, the Meissen porcelain factory continued to innovate in porcelain styles. The US also rose as a global centre of ceramic production with pioneers like Edwin Bennett, who patented single-fire overglaze decal technology in the 1860s.

By the late 19th century, industrialization enabled the mass production of ceramics at lower costs. However, there was also a counter movement towards art pottery and studio ceramics by individual artists as a reaction against industrialization. Important pioneers included Medley, Linthorpe Pottery, and Roseville in the US and William de Morgan in the UK.

20th Century

The 20th century saw major advancements in ceramic engineering and a growth in studio pottery. The Art Pottery movement, which started in the late 1800s, continued to thrive with potters like Adelaide Alsop Robineau pushing the boundaries of traditional ceramics. Robineau was considered a pioneer in art nouveau and art deco styles. Other influential art potters included Taxile Doat, Waylande Gregory, and William Grueby who helped elevate the status of ceramics as an artform.

Important innovations in glaze chemistry and kiln technology allowed potters to explore new techniques and aesthetics. The development of the electric kiln in the 1920s made firing more reliable and accessible. Ceramic engineering programs were established at universities, leading to advances in materials science. All of this supported the expansion of small studio pottery operations and schools.

Prominent ceramic artists who helped grow the studio pottery movement included Bernard Leach and Shoji Hamada who practiced traditional Japanese-inspired styles. Others like Peter Voulkos pushed ceramics in more abstract, sculptural directions. Voulkos is considered a leader of the Abstract Expressionist Ceramic Movement in the 1950s-60s along with artists like Paul Soldner. Overall, the 20th century saw ceramics transition from functional craft to innovative art form thanks to pioneering artists, new technologies, and a thirst for experimentation. [1] [2]

Contemporary Ceramics

In the contemporary period, ceramists have continued to innovate and push boundaries in the field. New materials like porcelain clay have become popular, allowing for thinner, more delicate pieces. Ceramists have also begun mixing ceramics with other media like wood, metal, and plastics in mixed media works.

Ceramics has also made major inroads into the world of modern art. Prominent contemporary artists like Jeff Koons and Ai Weiwei work extensively in ceramics. Their large-scale ceramic sculptures fetch tremendous sums at auction. Other artists like Clare Twomey and Bouke de Vries create conceptual and minimalist ceramics-based installations.

As the Contemporary Ceramics Gallery and Shop states, “Contemporary ceramic art over recent years has seen an explosion of ideas, processes and materials. Artists are pushing the boundaries, crossing disciplines and ignoring conventions.” https://www.contemporaryceramics.uk/ This interdisciplinary approach has reinvigorated ceramics in the contemporary art world.

Ceramics Uses

Ceramics have a wide variety of uses, both historically and in modern times. Some of the most common uses of ceramics include:

Pottery: One of the oldest uses of ceramics is for making pottery vessels for storage, cooking, and serving food and liquids. Pottery was crucial for early human civilizations and continues to be an important artistic medium today. Famous types of pottery include earthenware, stoneware, and porcelain.

Tiles: Ceramic tiles have been used to decorate floors, walls, countertops, and even ceilings for thousands of years. Tile allows for durable, easy-to-clean surfaces. Tiles come in a vast array of styles, colors, shapes, and designs.

Sanitaryware: The development of ceramic sanitaryware like toilets, sinks, and bathtubs was crucial for modern plumbing and sanitation. Ceramics are a hygienic, non-porous option for bathrooms and kitchens.

Tableware: Ceramic dishes, cups, and utensils have been the main option for serving food and drink since prehistory. Porcelain and bone china tableware remains popular today for its beauty and durability.

Art: Ceramic art includes pottery, sculptures, mosaics, and more. Clay is an extremely versatile and creative medium that allows artists to shape functional and decorative objects.

Technical/industrial ceramics: Advanced ceramics have many uses in engineering and technology, thanks to their heat resistance, hardness, chemical stability, and other properties. Technical ceramics are used in products like bricks, electronic components, machinery, medical implants, and spacecraft tiles.

(https://www.xometry.com/resources/materials/ceramics/, https://mse.umd.edu/about/what-is-mse/ceramics)

Future Outlook

The future of the ceramics industry looks bright, with exciting potential developments on the horizon.

One area to watch is 3D printing applications for ceramics. 3D printing technology allows for faster prototyping, more design flexibility, and customization in ceramic production. It may enable mass customization in areas like architectural designs. However, there are still challenges to overcome with 3D printing ceramics, such as optimizing technology for ceramic materials and improving structural integrity.[1]

Sustainability is also becoming an increasing priority in the ceramics sector. Companies are focused on developing sustainable manufacturing processes through renewable energy sources, recyclable and compostable materials, and reducing carbon emissions. The goal is to minimize environmental impacts. For example, researchers are finding ways to incorporate agricultural waste products into ceramic production.[2]

Looking towards the stars, ceramics hold promise for advanced space exploration applications. Their durability at extreme temperatures and resistance to chemicals make ceramics well-suited for use in spacecraft, rockets, satellites, and future space missions. Ceramic composites are also being developed for radiation shielding for astronauts. Ongoing research aims to improve the fracture toughness and thermal properties of ceramics for space.[3]

With innovative solutions on the horizon, the field of ceramics looks to continue evolving and expanding across industries.

[1] https://www.ceramicindustry.com/articles/103819-3d-printing-ceramics-how-it-works-application-challenges

[2] https://www.grandviewresearch.com/industry-analysis/ceramics-market

[3] https://straitsresearch.com/report/ceramics-market