What Type Of Clay Is In New Mexico?

New Mexico has a diverse geology that provides a wide variety of clay deposits across the state. Clays are formed from the chemical weathering and decomposition of rocks over time. In New Mexico, clay deposits are often found in areas with volcanic activity or marine sedimentation. The state has a long history of clay use by Native American groups for pottery, home construction, and other purposes. Some of the major types of clays found in New Mexico include kaolinite, bentonite, ball clay, fire clay, and common clay. Each clay type has unique properties and mineral compositions that lend themselves to certain applications and uses.

The varied geology across New Mexico produces clay deposits through several processes. In some areas, clays are residual deposits formed directly from the chemical weathering of igneous or metamorphic rocks. In other regions, clays accumulate as sedimentary deposits from erosion and transportation by water. New Mexico’s clay deposits provide important natural resources that continue to be utilized by modern industries today.

Kaolinite

Kaolinite is a clay mineral with the chemical composition Al2Si2O5(OH)4. It is an important industrial mineral with a wide variety of uses. Kaolinite is the most abundant clay mineral in soils and sediments in New Mexico, especially in the central and northern parts of the state [1].

Some key properties of kaolinite include its fine particle size, plate-like structure, low shrink-swell capacity, and whiteness. These make it useful for applications such as paper coating and filling, ceramics, fiberglass, paint, rubber, pharmaceuticals, and ink [2].

In New Mexico, major kaolinite deposits are located near Truth or Consequences, Santa Fe, and Socorro. The kaolinite is mined from hydrothermally altered rhyolite and tuff. Large reserves exist in the state to support continued industrial demand.

Bentonite

Bentonite is an absorbent clay formed from the weathering of volcanic ash. The main mineral component of bentonite is montmorillonite. Bentonite is known for its ability to absorb large amounts of water and expand significantly. The most important properties of bentonite are its rheological properties. When bentonite is mixed with water, the clay swells and forms a viscous fluid gel with thixotropic properties. Bentonite also has a strong colloidal property, allowing it to disperse evenly throughout water.

The largest known bentonite deposits in New Mexico are located around Clayton and Lakewood in the northeastern part of the state. Significant bentonite deposits are also located near Gila Bend and Lordsburg in southwest New Mexico, according to studies cited in the Selected Water Resources Abstracts[1]. New Mexico’s bentonite deposits are mainly used for drilling mud, foundry sand binder, and as a sealing agent in earthen dams and irrigation canals.

Ball Clay

Ball clay is sedimentary clay valued for its high plasticity and strength when fired. It tends to have a high shrinkage rate and is resistant to vitrification at higher temperatures.[1]

Ball clay is typically used in the production of porcelain and whiteware ceramics. It is often blended with other clays and minerals to achieve desired properties. Major uses are in tableware, sanitary ware, wall and floor tile, and electrical insulators.[1]

The largest deposits of ball clay in the United States are found in states along the Mississippi Embayment. New Mexico has smaller deposits located in the Mimbres Valley and north central regions of the state.[2] These ball clays are prized for their firing characteristics and used to produce pottery and other ceramic wares.

Sources:

[1] http://onlinelibrary.wiley.com/doi/10.1111/are.12696/pdf

[2] http://geoinfo.nmt.edu/publications/monographs/bulletins/downloads/159/Bulletin159.pdf

Fire Clay

Fire clay is a type of clay that can withstand high temperatures. It is resistant to heat and slags, making it ideal for lining furnaces, kilns, and fireboxes. In New Mexico, fire clay deposits are primarily located in Grant County around the towns of Bayard and Santa Rita, as well as in Luna County near Deming [1].

Some key properties of fire clay include its high alumina content, low iron oxide content, and high vitrification temperatures. It can withstand repeated heating and cooling without cracking or deteriorating. This makes it useful for lining high-temperature industrial furnaces and kilns in industries like steel, glassmaking, and ceramics. Fire clay has a high plasticity and can be molded into bricks, pipes, and refractory linings before firing [2].

Common Clay

Common clay is one of the most abundant clays found in New Mexico. It has a dull grayish to brownish color and possesses moderate plasticity and strength. Common clay consists primarily of kaolinite and some illite. Its properties make it suitable for manufacturing bricks, cement, and ceramics. According to the New Mexico Bureau of Geology and Mineral Resources, common clay is mined from five locations in the San Juan Basin in New Mexico [1]. The clay deposits were formed from the weathering of volcanic ash. Common clay has been used in New Mexico for centuries to make adobe bricks and other earthen construction materials due to its availability and adequate properties. Today, common clay remains an important industrial mineral in the state.

Polymorphism

Polymorphism refers to the ability of clay minerals to exist in different crystalline forms with the same chemical composition. The different crystalline structures are known as polytypes. The polymorphic varieties differ in the stacking sequence of the silicate tetrahedral layers.

The most common polytypes for the major clay mineral groups are:

- Kaolinite – kaolinite has a single tetrahedral silicate layer paired with a single octahedral hydroxide layer. The layers are held together by hydrogen bonding.

- Smectite – smectite has an expanding crystal structure with a central octahedral sheet sandwiched between two silica tetrahedral sheets. The layers are held together by van der Waals forces and exchangeable cations.

- Illite – illite has a similar structure to smectite but with potassium ions bonded between the layers which limits expansion.

- Chlorite – chlorite has a complex structure with an octahedral hydroxide sheet between two silica tetrahedral sheets, bonded by an interlayer brucite-like sheet.

The different crystal structures affect the properties and behavior of the clays. For example, the expanding lattice of smectite allows it to absorb large amounts of water, while the fixed lattices of kaolinite and illite do not expand to allow water absorption.

Clay Origins

Clay minerals primarily form from the chemical weathering of rocks over long periods of time. The weathering process breaks down feldspar and other silicate minerals into fine particles that crystallize into clays such as kaolinite, montmorillonite, and illite Clay mineral formation and transformation in rocks and soils. As water interacts with rock, it dissolves and alters chemical components, facilitating new clay mineral growth. Subsurface water circulation is critical in this formation process Subsurface water and clay mineral formation during the early history of Mars.

Specifically, the weathering of feldspar and mica leads to the formation of kaolinite clays, while the alteration of volcanic ash creates montmorillonite clays. The transformation of muscovite and feldspar forms illite clays. Over long timescales, burrial, pressure, and temperature changes can further modify and transform clay mineral structures in the subsurface Clay mineral formation and transformation in non-marine environments and implications for Early Cretaceous palaeoclimatic evolution: The Weald Basin (UK).

Industrial Uses

New Mexico has large deposits of clay that have been utilized in several major industries over the years. Some of the most notable industrial uses of New Mexican clays include:

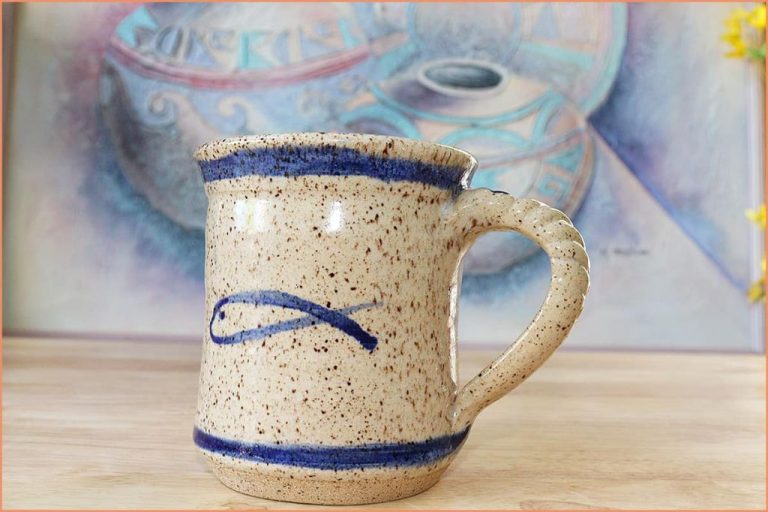

Pottery – New Mexico has a long tradition of Native American pottery making using local clays. Potters in places like Santa Clara Pueblo and Acoma Pueblo have been hand-crafting beautiful pottery from local clays for centuries. Today, NM pottery remains a major cultural tradition and industry. (https://geoinfo.nmt.edu/publications/monographs/bulletins/downloads/12/Bulletin012.pdf)

Brick and tile manufacturing – Bricks, roof tiles, floor tiles and other clay products have been produced commercially in New Mexico since the late 1800s. Major brickworks were located in Albuquerque and used local clay deposits. Clay bricks remain popular building materials today.

Cement manufacturing – New Mexico clays are used as a key ingredient in cement production at major plants in the state. The clay is mixed with limestone and used in the cement-making process.

Drilling mud – Bentonite clay is used to make drilling mud for oil and gas drilling operations. New Mexico’s ample bentonite reserves supply drilling mud products.

Cat litter – Bentonite clay from New Mexico is processed into cat litter at major production plants in the state and distributed widely.

Conclusion

New Mexico has a diverse variety of clay deposits, including kaolinite, bentonite, ball clay, fire clay, and common clay. These clays have formed through weathering and erosion of other sedimentary rocks over millions of years. They exhibit interesting properties like polymorphism, which allows them to change crystalline structure based on factors like temperature and pressure.

Clays like bentonite and kaolinite have many industrial applications due to their ability to absorb large amounts of water and swell. Bentonite is used for drilling mud, foundry sand binding, and as a sealant. Kaolinite is a crucial ingredient in paper, paint, rubber, and ceramic manufacturing. Ball clays help improve plasticity in ceramic bodies and are valued for their high strength when fired.

As demand grows for sustainable construction materials and greener manufacturing processes, the future looks bright for increased utilization of New Mexico’s bountiful clay deposits. With continued research and innovation, these clays may find new high-value uses that propel industries forward while reducing environmental impact. The geologic processes that originally deposited these clays will continue, replenishing resources for generations to come.