What Is The Average Kiln Temperature?

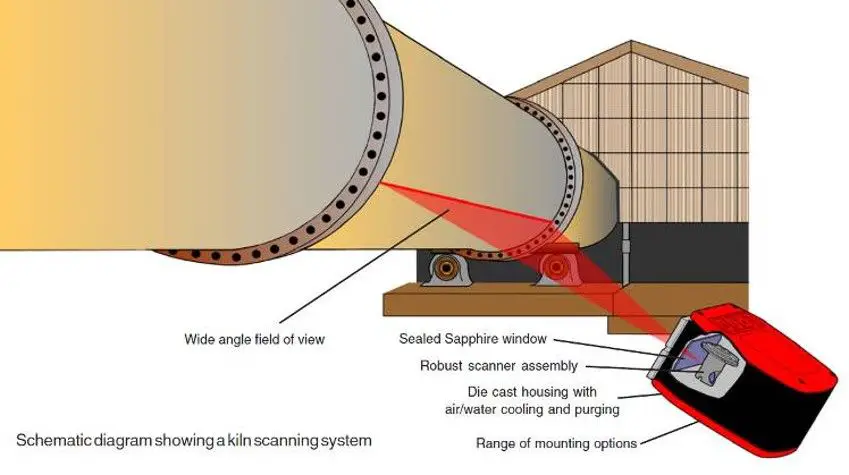

A kiln is a thermally insulated chamber that maintains high temperatures, used for a variety of high-temperature processes including firing pottery, drying lumber, creating glass, and other industrial applications (Kiln Definition & Meaning). Kilns allow materials to be efficiently heated to very high temperatures in a controlled environment. They are essential tools for creating ceramics, transforming raw clay into beautiful and functional pottery through the firing process.

While kiln designs and heating methods vary, they all serve the fundamental purpose of exposing materials to extreme heat. Average kiln temperatures depend on the desired outcome, but can range from around 1,000°F to over 2,000°F. This article will provide an overview of typical kiln temperature ranges for different applications, and discuss the factors that influence average firing temperatures.

Kiln Types

There are several main types of kilns used for firing ceramics and pottery. Some of the most common include:

Gas kilns – These kilns use natural gas or propane as the heating fuel. Gas kilns heat up quickly and allow precise control over the temperature. Downsides are potentially higher operating costs and the need for proper ventilation. Examples include downdraft and crossdraft kilns. (Ceramic Kilns)

Electric kilns – Electric kilns use heating elements that generate heat when electrical current flows through them. They provide a clean and convenient option, and newer digitally-controlled versions allow programming complex firing schedules. However, they may heat up slower than gas kilns. Common types are oval, rectangular and square. (Kilns and Firing)

Wood-fired kilns – These kilns use wood as the fuel, providing unique atmospheric effects from the flames and smoke. Firing can take days or weeks and requires constant stoking of the fire. The results are less predictable but can create natural, organic surfaces. Examples are anagama and noborigama kilns. (A Guide to Ceramic Kilns)

Each kiln type has advantages and disadvantages. The choice depends on factors like cost, desired effects, convenience, and firing time. Most ceramic artists use a combination of kiln types to achieve different results.

Factors Influencing Temperature

There are several key factors that influence the temperature inside a kiln during firing:

The type of fuel used to fire the kiln has a major impact on temperature. Kilns can be fired with gas, wood, electricity, or other fuels. Gas allows precise control over temperature. Wood firing involves more variability. Electric kilns offer very consistent temperatures.

The kiln’s size also affects how easily it can be heated up and cooled down. Large kilns tend to hold their heat well but can take longer to reach top temperatures. Small kilns heat up and cool down quicker but may not maintain an even temperature.

The amount of insulation around the kiln chamber influences temperature consistency and efficiency. More insulation holds in heat better and reduces temperature fluctuations. Insufficient insulation can lead to greater variability in temperatures.

Proper installation of the thermocouples (temperature sensors) is also important for accurate measurement and control of temperatures inside the kiln.

Knowing these key factors allows potters to choose the right kiln design and firing methods to achieve their desired temperatures for successful glaze chemistry and ceramic processing.

Temperature Ranges

Kilns are designed to reach a wide range of temperatures depending on the type of firing needed. Here are some typical temperature ranges for major kiln types:

Low-fire kilns generally reach temperatures between 1535°F and 1945°F (835°C to 1060°C). These temperatures are suitable for firing earthenware and some stoneware clay bodies. Low-fire glazes mature and become glasslike within this range. (Your Guide to Kiln Temperature Ranges for Pottery)

Mid-range kilns reach between 1945°F and 2372°F (1060°C to 1300°C). Mid-range stoneware clays and glazes become vitrified and water-tight at these temperatures. Most stoneware pottery is fired in this range. (https://www.soulceramics.com/pages/guide-to-kiln-temperature-ranges-for-pottery)

High-fire kilns achieve temperatures between 2282°F and 2642°F (1250°C and 1450°C). These high temperatures are necessary for firing porcelains and creating smooth, glass-like glazed surfaces. High-fire kilns allow clay and glazes to become extremely dense and durable. (Kiln Temperature Ranges)

Measuring Temperatures

Kiln temperatures are typically monitored and measured in a few different ways. Pyrometric cones (https://digitalfire.com/glossary/pyrometric+cone) are small pyramids made from precise mixtures of minerals that melt at specific temperatures. By placing these cones inside a kiln and observing how they melt, potters can determine when certain heat work temperatures have been reached. Another common method is using thermocouples – devices that measure temperature electrometrically. Thermocouples can be placed inside kilns and connected to external digital controllers, allowing real-time monitoring and control of temperatures (https://ir.library.oregonstate.edu/downloads/kw52j921j). Some kilns also have peepholes that allow visual checks on pyrometric cones during firing. In addition, Bullers rings, which are glass discs that deform at certain temperatures, were historically used to estimate kiln temperatures after firing was complete.

Average Temperatures

The average temperature for most ceramic kilns depends on the type of firing and clay being used. Here are some common temperature ranges:

- Low-fire (Cone 04-06): 1700-2100°F (900-1150°C) 1

- Mid-range (Cone 4-7): 2124-2264°F (1162-1240°C) 1

- High-fire (Cone 8-10): 2200-2345°F (1204-1285°C) 2

For mid-range clays, the most commonly used temperature is around 2200°F (1204°C). This allows the clay to vitrify properly without deforming. Low-fire clays are fired at lower temperatures, while high-fire clays need higher temperatures to reach maturation.

Regional Differences

The average kiln temperature can vary significantly between different regions and countries. According to one study, the average firing temperature for kilns in the Lingdong region of China during the Song Dynasty (960-1127 AD) was around 1,250°C with a standard deviation of 87°C (https://heritagesciencejournal.springeropen.com/articles/10.1186/s40494-019-0312-8). In contrast, kilns invented in Sèvres, France were designed to reach temperatures of 1,240°C in order to produce ceramic bodies that were waterproof and had a certain desired quality (https://en.wikipedia.org/wiki/Kiln).

Regional differences in average kiln temperatures can be influenced by the types of clay used locally, the ceramic styles and products produced, fuel availability, kiln construction methods, and cultural traditions around firing. For example, Porcelain production requires firing at very high temperatures of 1,200-1,400°C which is hotter than low-fire earthenware clays that can be fired at 1,000-1,100°C. The development of local clay resources and ceramic styles would impact the average temperatures needed.

There can also be variations between rural pottery operations using traditional kilns versus industrial ceramic production facilities with modern electric kilns. The scale of production and type of technology available places constraints on the temperatures that can be achieved on average.

Firing Techniques

The approach taken to fire ceramics can significantly impact the average kiln temperature achieved. Firing too quickly risks under-fired work with suboptimal strength. Conversely, firing too slowly wastes energy and risks over-firing. Most ceramic artists use one of three main firing techniques:

Slow Firing: Heating at less than 100°F per hour, slow firing allows clay to thoroughly dry and results in optimal glass formation and glaze chemistry. However, it requires meticulous monitoring and control of the kiln to maintain an even heat distribution. Slow firing typically achieves an average temperature around 2,100°F.

Fast Firing: Increasing the rate above 250°F per hour, fast firing is efficient but can cause flaws like cracking or shattering. It requires high-quality kilns able to rapidly generate and adjust heat. Fast firing normally averages around 2,300°F.

Ramp Hold Firing: This involves pre-programmed incremental temperature increases, like 100°F per hour up to 500°F, then 200°F per hour up to 1,000°F. Short hold times at certain temperatures allow heat to fully penetrate pieces. Ramp hold firing enables an average temperature around 2,200°F.

While approaches differ, maintaining control over heat flow is essential for achieving target temperatures. Programmable controllers allow adjusting to the specific clay bodies and glazes used. Consulting manufacturer guidance can prevent potential problems.

Sources:

{“Soul Ceramics. 2022. \”Guide to Kiln Temperature Ranges for Pottery.\” Soul Ceramics. March 17, 2022. https://www.soulceramics.com/pages/guide-to-kiln-temperature-ranges-for-pottery.”}

Recommendations

Here are some recommendations for ideal temperature ranges based on common uses for pottery:

For low-fire pottery like terra cotta, earthenware, and raku, aim for a temperature range between 1752-2102°F (950-1150°C). This lower temperature allows bright colors and decorative glazes. See this article for more details on low-fire temperature ranges.

For mid-range stoneware pottery, target a temperature between 2102-2232°F (1150-1220°C). Many stoneware clays vitrify and become water-tight within this range. Mid-range firings allow for a wide variety of glazes and colors. Refer to this guide on mid-range kiln temperatures.

For high-fire porcelain pottery, aim for temperatures between 2282-2482°F (1250-1360°C). High-fire brings out the translucency of porcelain clays. However, high temperatures limit glaze options. Check firing schedules and cone ratings to help determine the ideal peak temperature.

Always follow the manufacturer’s recommendations for the clays and glazes you are using. Test new pieces with witness cones to calibrate your kiln. Start low and slowly increase temperatures to find the optimal range for your pieces and purposes.

Conclusion

In summary, the average kiln temperature can vary greatly depending on the type of kiln, the firing technique, the type of clay and glazes used, and even regional traditions. However, most kilns tend to operate in a range between 1500-2400°F. Gas kilns generally fire on the lower end around 1500-2200°F, while electric kilns can reach the higher temperatures around 2000-2400°F needed for stoneware and porcelain. Kiln temperatures also depend on whether the firing is for bisqueware, glazes, or specialty techniques like raku. While specific kiln models may recommend target temperatures, the skill of the ceramicist in controlling airflow, heating elements, and observing cone packs is a critical factor. Adjustments during the firing process allow ceramists to achieve their desired results. With proper training and experience, ceramic artists learn to balance all these variables and successfully fire their pieces to temperatures that maximize the qualities of their clays and glazes.