Is S30V Better Than 1095?

S30V and 1095 are two popular types of steel used in knives and blades. S30V is a stainless steel developed by Crucible Industries, while 1095 is a high carbon tool steel. Comparing these two steels can help knife enthusiasts understand the differences in performance and help determine which may be better suited for different applications.

This article will provide an overview of S30V and 1095 steels, looking at composition, hardness, corrosion resistance, sharpness, edge retention, toughness, ease of sharpening, and price. The goal is to compare the advantages and disadvantages of each steel to understand where each excels and their ideal uses.

Composition

The key alloying elements in 1095 steel are 0.90-1.03% carbon and 0.9-1.2% manganese (https://knifeinformer.com/knife-steel-composition-chart/). The simple alloying makes 1095 relatively inexpensive to produce. It relies primarily on the hardening capabilities of carbon to attain hardness.

S30V steel contains 1.45% carbon, 14.0% chromium, 2% molybdenum and 4% vanadium (https://hudsontoolsteel.com/technical-data/steelCPMS30V). The significant amounts of chromium, molybdenum and vanadium in S30V give it much greater hardness, toughness and wear/corrosion resistance compared to 1095.

Hardness

The Rockwell hardness rating of 1095 carbon steel is typically around HRC 60-62, while S30V stainless steel has a hardness of HRC 58-60 [1]. This makes 1095 slightly harder than S30V. However, the hardness difference is quite small. Both steels are considered very hard on the Rockwell scale.

Increased hardness provides better edge retention and resistance to abrasive wear. But higher hardness also makes a steel more brittle. S30V’s slightly lower hardness gives it a bit more toughness compared to 1095, making it less prone to chipping or breaking under impact. 1095’s extra hardness provides marginally better edge retention, but the steel is more brittle as a result. Overall, the minor hardness difference between 1095 and S30V does not significantly impact their cutting performance.

[1] https://nitro-v-steel-vs-s30v.apotheke-im-ratio-baunatal.de/

Corrosion Resistance

When it comes to corrosion resistance, S30V is far superior to 1095 steel. S30V contains 13% chromium, while 1095 only has trace amounts of chromium at less than 1%. The higher chromium content of S30V makes it much more stain and rust resistant.

1095 carbon steel is known for having poor corrosion resistance and being susceptible to rust if not properly cared for. The lack of chromium and other alloying elements means 1095 can begin to rust if exposed to moisture or sweat. S30V contains enough chromium to provide good resistance against corrosion and rusting in comparison.

According to Source 1, the higher chromium of S30V gives it much better corrosion resistance compared to lower alloy steels like 1095.

Sharpness

S30V maintains its edge longer than 1095 due to its fine grain structure [1]. The tight grain size allows S30V to hold a sharp cutting edge well. While 1095 can be sharpened to a very fine edge, it will not retain that sharpness as long as S30V due to its coarser grain size [2].

1095 is relatively easy to sharpen due to its simple composition and lack of carbides. S30V is more difficult to sharpen than 1095 because the vanadium carbides in S30V are very hard and abrasion resistant. However, S30V can be sharpened to a very keen edge because of its fine grain size once the proper sharpening methods are used [3].

[1] http://bushcraftusa.com/forum/threads/benchmade-bushcrafter-cpm-s30v-vs-1095-knives.346532/

[2] https://www.bladeforums.com/threads/s30v-steel-vs-1095-high-carbon-steel.686253/

[3] https://forum.spyderco.com/viewtopic.php?t=85480

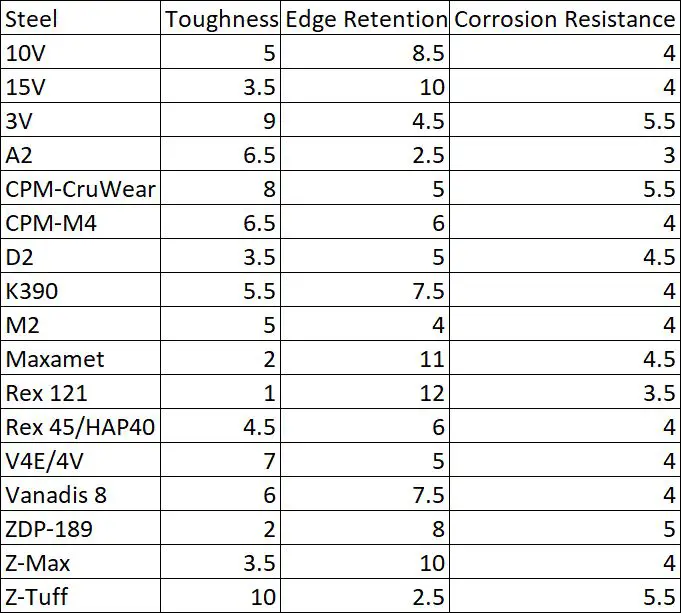

Edge Retention

Edge retention refers to how long a knife’s edge will stay sharp with regular use. This is an important factor when comparing knife steels like S30V and 1095.

S30V generally has better edge retention than 1095 due to its higher hardness and finer grain structure. S30V typically scores 60-62 on the Rockwell hardness scale, while 1095 is around 56-58 HRC. The harder steel of S30V is more resistant to abrasion and wear, enabling the edge to stay sharper for longer (https://knifeade.com/420hc-knife-steel/).

Additionally, S30V has a fine-grained carbide structure which is more dense and uniform compared to 1095’s coarser grain. The finer grain size reinforces the edge and provides more support against micro chipping and abrasive wear. This further enhances S30V’s edge holding capability over 1095.

However, while S30V holds an edge for longer, 1095 is easier to sharpen when the edge does eventually dull. 1095’s lower hardness and larger carbides require less effort to abrade and form a new keen edge. So S30V has superior edge retention, but 1095 can be resharpened more easily.

Toughness

Toughness refers to a steel’s ability to resist chipping, cracking or breaking. It involves two main factors – ductility and impact resistance, versus brittleness.

1095 steel has decent toughness for a high carbon steel, but is considered more brittle than S30V. 1095 tends to be prone to chipping when put under stress, especially when the steel is hardened to achieve high hardness levels. S30V has much greater toughness and impact resistance due to its blend of chromium, vanadium and molybdenum alloying elements. The fine carbides in S30V allow it to flex rather than chip out.[1]

S30V is designed to have high ductility along with strength and hardness. It can withstand impacts and lateral stresses better than 1095 without cracking or chipping. 1095 becomes increasingly brittle the harder it gets. S30V maintains its toughness even at high hardness levels up to 60 HRC, while 1095 becomes too brittle above 57-58 HRC.[2]

For tasks that involve impact forces like chopping or batoning, S30V’s superior toughness gives it a clear advantage over 1095 carbon steel.

[1] https://forum.spyderco.com/viewtopic.php?t=85480

[2] http://bushcraftusa.com/forum/threads/benchmade-bushcrafter-cpm-s30v-vs-1095-knives.346532/

Ease of Sharpening

When it comes to refreshing an edge in the field, 1095 has the advantage over S30V. As a simple carbon steel, 1095 is relatively easy to sharpen with just a basic field sharpener. S30V, on the other hand, contains large amounts of vanadium carbides that can be difficult to abrade and sharpen without more advanced equipment (https://nitro-v-vs-s35vn.def-nation.de/). The large carbides in S30V cause issues with carbide pullout during sharpening, making it harder to get a fine edge. While S30V can attain a very fine edge, it requires more effort to refresh than 1095 in a field or survival situation.

Price

There is a significant cost difference between 1095 and S30V steel. 1095 is an inexpensive, simple carbon steel that can be found for around $0.50 per pound when purchased in bulk quantities. S30V, on the other hand, is a premium powder metallurgy stainless steel made by Crucible Industries that costs upwards of $6 per pound.

The high cost of S30V is largely due to the complex production process required to make powder metallurgy steels. The fine powder and sophisticated manufacturing result in a very high performing steel, but also drive up the price substantially compared to a simple forged carbon steel like 1095. This means S30V knives will usually cost significantly more than knives made from 1095.

For knife makers and manufacturers, 1095 provides an affordable steel choice that can yield durable and functional knives. The low cost per pound allows selling knives at lower prices while still maintaining profit margins. However, for buyers willing to pay premium prices, S30V offers vastly increased edge retention, corrosion resistance, and all-around capability. The price difference reflects the significant performance upgrade S30V provides over 1095.

Summary

S30V and 1095 are two of the most popular and widely used knife steels. They have some notable differences that make each one better suited for particular uses.

S30V has higher hardness and edge retention than 1095, making it ideal for applications that require a fine, durable edge like camping knives and kitchen knives. It’s very resistant to corrosion and wear. However, it’s less tough than 1095 and more difficult to sharpen due to its high carbon and vanadium carbide content.

1095 is tougher and easier to sharpen than S30V, but doesn’t hold an edge as long. It has moderate corrosion resistance. 1095 is a great choice for large knives that need to withstand impact like survival knives, as well as for knives that require frequent sharpening like pocket knives. It’s also more affordable than premium steels like S30V.

In summary, S30V is better for fine edges and maximum edge retention while 1095 is tougher and easier to sharpen. Consider the intended use of the knife and maintenance requirements when choosing between these two quality knife steels.