Are Handmade Clay Mugs Microwave Safe?

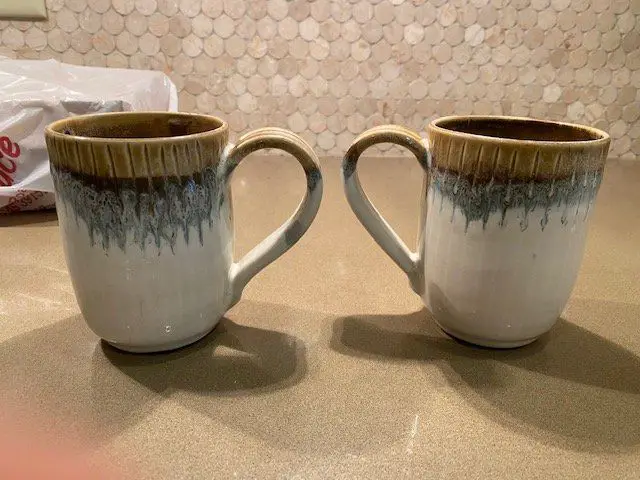

Ceramic mugs have been popular home and kitchenware items for decades, with their cozy, classic style making them a staple in many households. In recent years, the demand for unique, artisanal mugs from independent ceramic artists has skyrocketed. Brands like Rae Dunn have amassed huge followings, with collectors obsessively tracking down the latest mug releases (Gotta Have That Cute Mug? Act Fast.). The craze highlights the widespread appeal of the humble mug as both a practical vessel for enjoying drinks and a decorative statement piece.

With ceramic mugs being so prevalent, many mug owners wonder if their handmade pieces are safe to use daily conveniences like the microwave. As durable and versatile as ceramic mugs are, they do have limitations when it comes to exposure to extreme temperature changes. This article will explore the properties of ceramic clay, firing processes, and microwave heating to help mug owners understand if and when it’s safe to microwave their handcrafted mugs.

Clay Material Properties

Clay is composed of hydrous aluminium phyllosilicates, sometimes with variable amounts of other minerals such as quartz, carbonates, iron oxides, and magnesium. Clays develop plasticity when mixed with water, due to the particles being plate-shaped, thus allowing the plates to slip and slide past one another. There are various types of clay used in pottery, with differing levels of plasticity, shrinkage, and porosity when fired.

According to https://www.potterycreative.com/types-of-clay-for-pottery/, porosity refers to the tiny holes and pores within the fired clay body, which allow absorption of water. Higher porosity means the clay will absorb more water. Earthenware clays are the most porous, while stoneware and porcelain clays are less porous. Porosity affects the durability and water absorption of the finished pottery piece.

The three main categories of clay are earthenware, stoneware, and porcelain. According to https://thepotterywheel.com/types-of-clay-for-pottery/, earthenware clays contain more impurities and are fired at lower temperatures, resulting in more porous clay that is less dense and durable. Stoneware clays are denser and less porous due to higher firing temperatures. Porcelain clays are the purest with low porosity, firing to a glassy finish.

Firing and Glazing

Proper firing and glazing are critical steps when making clay mugs microwave safe. Clay mugs must be fired to high temperatures, typically between 2100°F and 2300°F, to fully vitrify the clay material. This makes the mug non-porous and prevents leaching of chemicals into foods and drinks. According to How to Glaze a Mug!, glazes provide an impervious coating and decorative finish to mugs after firing. Glazes are specially formulated mixtures of minerals and compounds that melt and fuse to the mug’s surface during firing. Food-safe glazes approved for functional ware contain no toxic materials and create a barrier preventing porous clay bodies from absorbing liquids.

Microwaves and Heating

Microwaves are a form of electromagnetic radiation with wavelengths ranging from about one meter to one millimeter (3 GHz to 300 GHz frequency). Microwave ovens operate at a frequency of 2.45 GHz.

Microwaves are able to cause dielectric heating in materials containing water molecules, like most foods. When exposed to microwaves, the water molecules rotate and vibrate from the rapidly changing electric field. This molecular movement creates friction and heat, quickly cooking the food from the inside out.

According to TDK, heating increases as the vibrations become more intense, transferring electromagnetic energy into thermal energy. This allows microwave ovens to heat food rapidly and efficiently, using the water already present in the food.

Thermal Shock

Thermal shock occurs when there is rapid temperature change in a ceramic material, which causes different parts of the ceramic to expand at different rates. This differential expansion induces stress in the material that can lead to cracking or fracture.

Pouring hot liquids like coffee or tea into a cold ceramic mug is a common way thermal shock can occur. The hot liquid quickly heats the inner surface of the mug, causing it to rapidly expand. However, the inside expands quicker than the outer thicker walls and base. This imbalance in expansion rates causes stresses that can crack the mug.

According to the Digital Fire glossary, thermal shock refers to “stresses imposed on a ceramic by the volume changes associated with sudden shifts in temperature.” It states risks are higher when there is a thinner section that changes temperature faster than a thicker one.

On Reddit, a potter confirms handmade mugs can withstand hot liquids but advises preheating first: “You’ll want to warm up the mug before pouring boiling water in to prevent thermal shock” (source). This helps equalize the temperature change across the mug.

In summary, rapid heating of a cold ceramic can cause dangerous stresses. Preheating clay mugs helps minimize thermal shock risks when using with boiling liquids.

Microwave Safety Standards

Microwave ovens sold in the United States must comply with safety standards set by the FDA (Food and Drug Administration). These standards limit the amount of microwave radiation that can leak from an oven throughout its lifetime to 5 milliwatts per square centimeter at approximately 2 inches from the oven surface.

The FDA standard (21 CFR 1030.10) requires that microwave ovens allow no more than 1 milliwatt of microwave radiation to leak out while they are operating. Additionally, they may not exceed a 5 milliwatt leakage level over the lifetime of the oven.

This leakage limit assures that the microwave radiation from these products is well below the level known to harm people.

In the EU, microwave ovens must comply with the IEC 60335 Household and similar electrical safety standard. This standard sets safety requirements including limits on radiation leakage similar to the FDA standards.

Compliance is validated through testing protocols defined in standards like IEC 60519-3 which cover methods for measuring microwave leakage.

Manufacturer Guidance

While clay mugs are generally considered microwave safe, it’s always best to follow the official guidance provided by the manufacturer. Many brands that produce handmade clay mugs, such as Brand X, provide clear instructions on their product pages or tags.

For example, the Brand X product pages state that their clay mugs are microwave safe and meet FDA requirements. The tags on Brand X mugs also say they are safe for microwave use.

Checking the manufacturer’s recommendations provides definitive guidance on if a specific clay mug can be microwaved. Their tests and quality standards determine the microwave safety of their products.

So while clay mugs may generally be microwave safe, always verify with the manufacturer of a specific mug before heating it up.

Testing Methods

There are some simple ways to test the microwave safety of handmade clay mugs at home before using them to heat food or drinks:

Do a water test – Fill the mug with water and microwave it for 30 seconds. Check for cracking, crazing, or other damage. If there are no issues, the mug should be safe to use.

Test with a microwaveable item – Heat something microwave-safe like a cup of water or plate of food in the mug. Monitor it closely and look for any reactions from the mug itself.

Try short heating times – Only microwave handmade mugs for short intervals like 30 seconds at first. Check for issues and gradually increase heating time if the mug seems stable.

Inspect carefully after heating – Let the mug cool fully and inspect for hairline cracks, crazing, blistering or peeling glaze. Any of these indicate the mug is not suitable for microwave use.

Do multiple tests – Test the mug several times to determine if any issues develop with repeated microwaving. Long term microwave use can cause wear even if initial tests seem fine.

Best Practices

When microwaving handmade clay mugs, it’s important to take some precautions:

First, always check the manufacturer’s guidance to see if the specific mug is labeled as microwave-safe. According to Mammoth & minnow, handmade ceramics are generally fine to microwave as long as they don’t have metallic glaze, but each piece may vary [1].

Pottery Crafters recommends starting with short microwave times, such as 2-3 minutes to heat water or milk. Extended microwaving can lead to cracking or breaking [2]. Remove the mug carefully with oven mitts.

Allow the mug to rest for a few minutes before handling to prevent thermal shock. According to Quora users, a sudden temperature change can damage the mug [3].

Inspect the mug afterwards – multiple microwavings may cause crazing (fine cracks) over time. Consider handwashing instead of dishwashing, which can erode glazes.

With proper care, most handmade clay mugs can be safely microwaved for short bursts to heat foods and beverages. Always check manufacturer guidance and start with conservative cook times.

Conclusion

In summary, handmade clay mugs can generally be considered microwave safe if they meet certain criteria. Unglazed terra cotta clay should always be avoided in microwaves due to porosity. Vitreous stoneware and porcelain mugs, especially those labeled microwave safe by the manufacturer, are the safest options. They should be free of cracks and have a sturdy handle. Glazes should be tested to confirm they don’t contain materials that interact with microwaves. Thermal shock can be prevented by heating gradually at lower power for short increments, and allowing resting time before handling. With care and proper use, handmade clay mugs can be a functional, convenient, and safe option for microwave beverages.

The key recommendations are:

– Choose vitreous stoneware or porcelain clay bodies

– Ensure glazes are microwave safe and lead-free

– Look for mugs specifically labeled as microwave safe

– Inspect for cracks, crazing, flaws before use

– Handle with care to prevent thermal shock

– Gradually reheat in short increments at lower power

– Allow resting time before removing mug from microwave

– Always refer to manufacturer guidance when available