How Do You Keep Silicone From Sticking To Mold?

Silicone is a popular material for making molds due to its flexibility and ability to reproduce fine details. However, a common problem that mold makers face is silicone sticking to the mold, which can damage the mold and ruin castings. Preventing silicone from adhering to the mold surface is important for clean demolding and reuse of the mold.

There are several techniques available to keep silicone from sticking to molds. Proper mold preparation, using release agents, degassing the silicone, and proper pouring and curing methods can all help produce flawless castings. This article provides an overview of the causes of silicone sticking and actionable solutions to prevent adhesion, resulting in smooth, non-stick molds and perfect castings every time.

Causes of Sticking

Silicone can still sometimes stick to the mold surface, even when using a release agent. This is often caused by:

- Surface tension – The high surface tension of liquid silicone can cause it to cling to the mold surface.

- Insufficient mold release agent – Not using enough release spray or powder can lead to sticking.

- Incompatible materials – Certain porous or adhesive materials like wood, foam, or tape may interact with the silicone and cause bonding.

Proper mold preparation and release agents are key to preventing surface tension and incompatibility from causing silicone to stick. As Smooth-On notes, “Although silicone mold rubber won’t stick to much and has the best release properties of the most common mold making materials used today, it may stick to some surfaces.” Using the right release spray formulated for silicone can create a protective barrier.

Choosing the Right Mold Material

When choosing a material to create a mold for silicone, it’s important to consider the benefits and drawbacks of different options. Some common mold materials include:

Metal – Metals like aluminum and steel can create very durable molds that stand up to repeated castings. However, they can be more expensive and require more specialized tools to fabricate the mold.1

Plastic – Plastics like polyurethane resin can be easy to work with and make molds from. But they may not last as long as metal molds. Plastics are generally a more budget-friendly option.2

Wood – Wood is an inexpensive, accessible material for quick, simple molds. However, wood is prone to warping and deteriorating over repeated uses. It works better for one-off casts.

For casting silicone specifically, plastics like polyurethane or epoxy resins often work very well. The smooth surface helps prevent silicone from sticking too aggressively. Many silicone mold makers recommend avoiding porous materials like wood or plaster.

Proper Mold Preparation

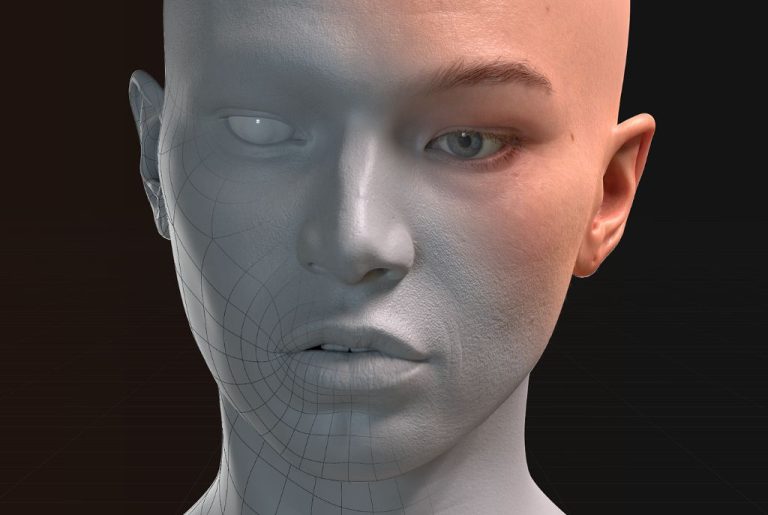

![]()

Before pouring silicone into a mold, it is crucial to properly clean and prepare the mold surface. This helps prevent the silicone from sticking and makes unmolding much easier. There are a few key steps to properly prep a mold:

Thoroughly clean the mold to remove any dirt, dust, oils or other contaminants. Warm soapy water works well for most materials. Ensure the mold is completely dry before moving to the next step.

Apply a thin layer of mold release agent onto all surfaces that will contact the silicone. Mold release agents prevent the silicone from bonding to the mold. There are two main types of mold releases:

- Spray-on release agents, such as Universal Mold Release or Ease Release 200. These are misted onto the surface in a light coat.

- Brush-on release agents and waxes, like petroleum jelly or carnauba wax. These are brushed on evenly.

Soft surfaces like wood, plaster or clay may require multiple coats. Let the release agent dry fully, usually about 30 minutes between coats. Carefully follow the manufacturer’s directions for best results.

Properly prepping the mold takes a bit of time upfront, but prevents headaches with sticking and unusable molds later on. Investing in high quality release agents suited for silicone molding ensures the silicone will release easily every time.

Using Release Sprays

Release sprays provide an evenly distributed layer to prevent the silicone from sticking and enable easy release after curing. There are two main types of mold release sprays:

Silicone-based sprays contain some silicone in a solvent carrier. They provide good release but can slightly inhibit platinum-cure silicone from curing against the mold. Some popular silicone-based sprays are Mann Ease Release 200 and Alumilite’s Amazing Mold Release.

Wax-based sprays contain a micro-fine wax dispersed in a solvent. They provide excellent release for most materials and won’t inhibit platinum-cure silicone. Smooth-On’s Universal Mold Release is a widely used wax-based spray.

For best results, hold the can 6-10 inches from the mold surface and apply 2-3 thin, even coats allowing 10-15 minutes of drying time between coats. Spray the mold evenly on all surfaces that will contact the silicone. Too much build-up can leave residue on the castings, while too little may not provide full release. Let the final coat become tacky before pouring the silicone.

Using Release Powders

Powders such as talc, cornstarch and baby powder can be effective, affordable substitutes for commercial silicone release sprays. These work by creating a thin barrier between the silicone and the mold surface. Some common powders used are:

- Talc – finely ground mineral powder, often used for cosmetics.

- Cornstarch – derived from corn, used for cooking and baking.

- Baby powder – typically made of talc and/or cornstarch.

To apply powder evenly, sprinkle a light coat over the entire mold surface and spread around using a brush. Tap the mold to remove excess powder before pouring in silicone. Be cautious not to inhale powders during the process. Reapply powder between pours for multi-part molds.[1]

Compared to commercial sprays, powders are very affordable, readily available and provide reasonably good mold release. However, the application process can be messy and powders may not create as clean of a release barrier as a liquid spray. Proper technique is required to coat the mold effectively without using excess powder. Overall, powders are a convenient alternative for hobbyists but sprays are preferable for frequent large-scale casting.

Degassing the Silicone

Trapped air bubbles in the silicone rubber can lead to sticking problems when unmolding finished parts. According to Smooth-On, trapped air bubbles cause areas with reduced strength and failure points in the cured silicone matrix. When demolding parts, the air pockets create weak spots that can tear or stick.

To remove air bubbles, it is highly recommended to degas or vacuum the silicone prior to pouring it into the mold. This can be done using a vacuum degassing chamber, or more DIY methods like placing the mixing container in a pressure pot or even a desiccator attached to a vacuum pump. According to comments on Reddit, degassing for 2-3 minutes under 29+ inches of mercury vacuum will eliminate most air bubbles and result in a strong, bubble-free silicone mold.

Be sure not to over-vacuum the silicone, as this can start to pull out fillers. Follow recommended vacuum times from the silicone manufacturer. Degassing helps create flawless molds that will have a smooth surface and cleanly release parts.

Pouring the Silicone

When pouring the silicone into the mold, it’s important to go slowly and carefully to avoid trapping bubbles. According to Formlabs, the silicone should be poured in a thin, steady stream, aiming for the lowest part of the mold. This allows air bubbles to escape to the surface. Once the silicone has been poured, give the mold a gentle tap on the table to help dislodge any remaining bubbles.

It’s crucial to allow the silicone adequate time to cure properly. Silicone cures from the outside-in, so larger molds need significantly more time. Refer to the manufacturer’s instructions, as cure times can range from 20 minutes to 48 hours depending on the type of silicone. The silicone should not be unmolded until it is fully cured. If rushed, the mold may tear or deform easily.

Unmolding and Troubleshooting

Proper cure time is essential for clean unmolding. Silicone molds typically require 24-48 hours to fully cure before attempting to unmold. Rushing this process can lead to sticking.

When ready to unmold, start by gently flexing the mold to break the seal. Slowly work around the edges, gradually easing the cast part out. Avoid prying or forcing the mold open aggressively.

If sticking persists, do not keep forcing the mold. Set it aside and allow additional cure time. You can also try placing the mold in the freezer for 30 minutes before trying again. The cold temperatures help shrink and release the silicone.

As a last resort if sticking still occurs, try lightly dusting mold release powder onto problem areas and gently working the cast part free. Be aware this may leave a texture on the finished casting. Thoroughly clean and re-prep the mold before casting again.

Proper mold preparation and degassing are key to preventing sticking in the first place. But allowing full cure time and unmolding with care is important to remedy any issues. With patience, silicone molds can be reused many times without sticking.

Summary

The key solutions for preventing silicone from sticking to molds are proper preparation, using release agents, and proper pouring and unmolding techniques.

Taking the time to properly prepare the mold surface is crucial – any contamination or roughness can lead to sticking. Smooth, non-porous surfaces work best. It’s also important to apply release agents like sprays or powders to create a barrier between the silicone and mold surface.

Degassing the silicone prior to pouring helps prevent air bubbles that can suction to the mold surface. Pouring gently in a thin stream and allowing time for the silicone to set ensures proper release. Unmolding with care and patience prevents tearing or friction that can lead to sticking.

With the right preparation and techniques, it is possible to cleanly unmold silicone parts from their molds. Proper process is key to preventing the frustration of parts sticking.