The Clay Conundrum: Deciphering Types And Applications

Clay is a mineral found in the earth that has many uses and applications. While there are various types of clays, each have unique properties that determine how they can be utilized. This article will provide an overview of common clay types, their compositions, and how they are applied across different industries and purposes. Understanding the distinctions between clay varieties allows us to better leverage their individual strengths.

We will explore some of the most prevalent clays like kaolin, ball clay, fire clay, and bentonite. Their mineral makeups differ, resulting in divergent levels of plasticity, firing temperatures, and more. Learning these attributes helps decipher which clays are best suited for ceramics, construction materials, cosmetics, medicine, and other domains.

In addition to introducing the array of clay categories and their qualities, we will also delve into the many applications of clays across history and modern usage. From pottery to pharmaceuticals, clays provide solutions for an extensive range of products and needs. We will cover some of the most common current uses as well as future possibilities as technology develops.

Understanding clays at a deeper level allows us to maximize their potential. This article aims to demystify these versatile minerals and provide key insights into properly leveraging the unique advantages of different clay types.

Common Clay Types

Clay can be classified into several major groups including kaolinite, illite, smectite, and chlorite according to their crystalline structure (Kumari, 2021). The most common types of clays used in various applications include:

Kaolin Clay – This very pure clay is white in color and has a fine particle size. It is ideal for use in ceramics, paper, paint, and cosmetics (Mineral Education Coalition).

Ball Clay – This is a kaolinite clay with high plasticity and strength when fired. It is mixed with other clays to improve workability and strength.

Fire Clay – Fire clays have high refractoriness, meaning they can withstand very high temperatures. They are used to line furnaces and fireplaces.

Bentonite – Bentonite clays absorb high amounts of water and can expand up to 15 times their dry size. They are used for drilling mud and cat litter.

Red Earthenware – These low-firing clays produce a distinctive red color. They are used for flower pots, roof tiles, and decorative items.

Stoneware – This dense clay has high strength and low porosity after firing. It is used for everyday dishes and art wares.

Kaolin Clay

Kaolin clay, also called China clay or white clay, is one of the gentlest clays used in skincare. It is made up of kaolinite, which is a white, chalky mineral formed from weathered granite rock (Source: https://skinpharm.com/blogs/blog/kaolin-clay-benefits). Kaolin clay is known for its bright white color and purity. Some of the key benefits of kaolin clay include:

- Absorbing excess oil and impurities from the skin

- Gently exfoliating dead skin cells

- Soothing irritated or inflamed skin

- Providing minerals like silica and zinc to nourish the skin

Due to its mildness, kaolin clay is suitable for all skin types including sensitive skin. It is commonly used in skincare masks and cleansers to gently purify the skin. Kaolin clay is also used extensively in cosmetics to create smooth textures and act as a bulking agent. In addition, it is a key ingredient in porcelain and ceramic manufacturing.

Ball Clay

Ball clay is a vital ingredient for many ceramic materials due to its superior plasticity and high ‘dry strength’ which helps retain the shape of products during the drying process. This plastic white-firing clay is composed primarily of kaolinite with smaller amounts of illite, quartz, feldspar, and organic materials. Ball clay is an essential component in bricks, ceramic tiles, and porcelain bodies where it improves mechanical strength, plasticity, shrinkage and green strength.

Ball clay’s fine particle size, high plasticity, and light firing color make it an indispensable raw material in whiteware ceramics such as porcelain (“Ball clay for plasticity and added strength in ceramics – Imerys”). When used with other clays, feldspar and quartz, ball clay enables excellent plasticity for shaping as well as a good white color after firing. For wall and floor tiles, ball clay reduces drying shrinkage cracks and allows fast, efficient firing (“Ball clay overview, properties and what is it used for – Imerys”).

Fire Clay

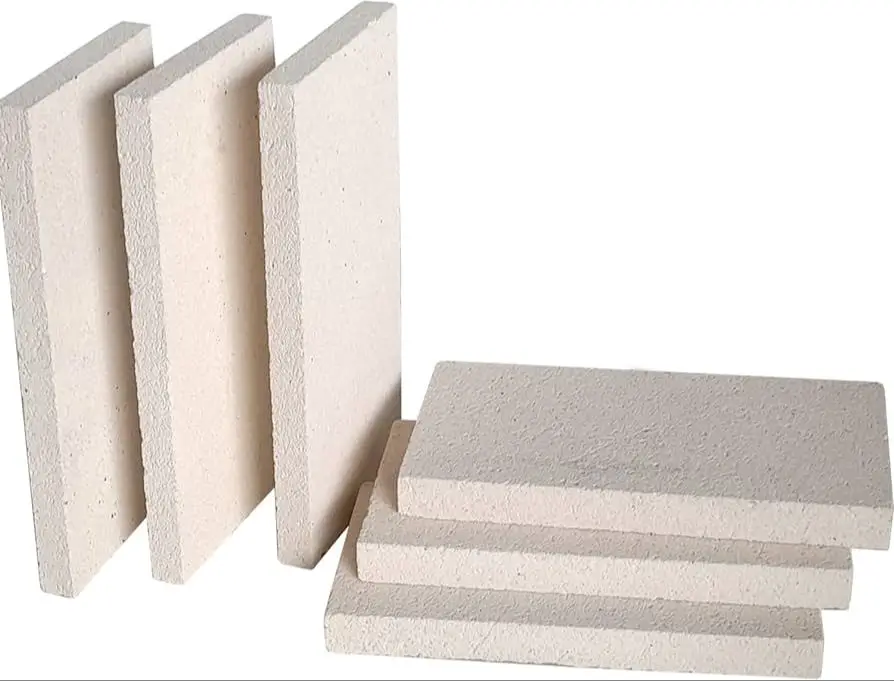

Fire clay is a type of clay that can withstand extremely high temperatures (https://en.wikipedia.org/wiki/Fire_clay). It has a high content of alumina and silica, giving it a high melting point. Fire clay is commonly used to line kilns and fireboxes and in the manufacture of fire bricks (https://theconstructor.org/question/what-are-the-properties-and-significance-of-fire-clay/).

The chemical and physical properties of fire clay allow it to withstand the high temperatures inside kilns and furnaces. It resists thermal shock and has good insulating properties. Firebricks made from fire clay can withstand temperatures up to 1,800°C (3,270°F). This makes fire clay invaluable for lining anything with an open flame such as forges, fireplaces and chimneys.

Bentonite Clay

Bentonite clay, also referred to as Montmorillonite clay, is an absorbent clay formed from volcanic ash. It is named after Fort Benton, Wyoming where it was first discovered in the 1880s. Bentonite clay is composed of aged volcanic ash and has a high concentration of minerals like silica, calcium, sodium, magnesium, and iron (1).

Some of the key characteristics and uses of bentonite clay include:

- Highly absorbent and can absorb 5-10 times its weight in water

- Has a strong negative ionic charge allowing it to absorb toxins, heavy metals, impurities, and other substances

- Used in industrial applications for drilling, foundry, and cement due to its binding, thixotropic, and absorbent properties

- Utilized in cat litter products for its absorbency

- Used in cosmetics and skin care products like masks, soaps, and creams for its detoxifying and cleansing properties

- Taken internally in the form of supplements or clay drinks to remove toxins, improve digestion, and promote gut health

While generally considered safe for external use, some potential side effects have been reported when ingesting bentonite clay over long periods, so it’s best to consult a doctor before consuming (2). Overall, bentonite clay has a wide range of practical uses thanks to its absorbent nature and mineral composition.

Red Earthenware

Red earthenware is a low-fire clay that is known for its reddish-orange color. It fires at lower temperatures typically between 1745-1915°F (950-1050°C) making it an earthenware clay body (1). The clay contains iron oxide which gives it the distinctive red color. Red earthenware has excellent working properties making it easy to hand build or throw on the potter’s wheel. It has a smooth, plastic texture that becomes leather-hard quickly during the drying process. The clay can be distressed or impressed when leather-hard to create interest in the surface design.

Red earthenware is commonly used for items like flowerpots, roof and floor tiles, and garden ornaments that only require low temperature firing (2). It can be glazed or painted and accepts stains well. The red clay pairs nicely with white slip or engobe to create contrast and visual depth. When fired, the raw clay turns a terra cotta red color which gives any glaze applied a warmer tone. Red earthenware’s low firing temperature and bold color make it a versatile choice for potters looking to create decorative or functional ceramic pieces.

(1) https://ceramicartsnetwork.org/daily/pottery-making-techniques/making-clay-tools/low-fire-clays/

(2) https://www.opticartsupply.com/versatile-blick-red-earthenware-clay-a-potters-dream-archive/

Stoneware

Stoneware is a hard, vitrified, water-tight ceramic made primarily from ball clay (https://digitalfire.com/glossary/stoneware). It is fired at high temperatures ranging between 1200°C to 1300°C which causes the clay to become non-porous. The high firing temperature makes stoneware durable, dense, and resistant to scratches. Stoneware maintains its strength when wet and does not require a glaze to be waterproof, though glazes are often applied for aesthetics and to create a non-porous surface.

The high plasticity of stoneware clay makes it excellent for creating pottery shapes and retaining fine details. Common uses of stoneware clay include tableware such as plates, mugs, and bowls, as well as decorative pottery, tiles, and large storage vessels. The colors of finished stoneware pieces range widely from light grey to dark brown or even black depending on the clay composition and firing temperature (https://royalbaliceladon.com/blogs/news/exploring-stoneware-characteristics-safety-and-myths-debunked). Stoneware’s durability and ability to withstand thermal shock makes it ideal for ovenware and cooking vessels.

Compared to porcelain clays, stoneware contains more iron and feldspar which results in greater strength and more visible color variation. Porcelain and bone china have very white and translucent qualities, while stoneware retains more of the natural earth tones from the clays. Many ceramic artists prefer stoneware for its high workability and wide range of potential glazing effects.

Clay Applications

Clays have a wide variety of applications across many different industries. Some of the most common uses of clays are in construction, ceramics, paper, cosmetics, and pharmaceuticals.

In construction, clays are a key ingredient in bricks, tiles, and cements. The binding properties of clays help hold building materials together (Murray, 1991[1]). Clays including kaolin are also essential for the production of ceramic materials like porcelain and bone china. The white kaolin clay provides strength and workability while firing into a translucent white finished product (“Industrial Application of Clays and Clay Minerals”[2]).

Clays are utilized in paper production to coat the paper and improve brightness, opacity, and ink receptivity. Bentonite clay is often used as a filler and coating pigment. In cosmetics, clays absorb oil and help purify skin. Kaolin and bentonite clays are common active ingredients in skin care products. In pharmaceuticals, clays can help deliver medications and provide controlled release properties.

Overall, clays are incredibly versatile materials finding uses across construction, manufacturing, healthcare, personal care, and more industries due to their abundance, affordability, and unique physical properties.

Conclusion

In summary, understanding the different types of clay and their unique properties is essential for determining the right applications. Clays vary considerably in their composition, plasticity, firing temperatures, colors, and more. Knowing if a clay is high or low plasticity, refractory or not, stoneware versus earthenware, allows potters and other users to select the optimal material for their needs.

Kaolin’s white color makes it ideal for porcelain, while fire clay withstands the highest heat. Ball clays promote strength and plasticity in ceramic bodies, and bentonite clays act as bonding agents and add workability. Red earthenware clays are some of the most abundant and versatile for everyday pottery and ceramics.

Mastering the nuances of clay types gives artisans and makers creative freedom in their craft. As we’ve seen, not all clays are created equal. Understanding their differences unlocks new possibilities and ensures the best results for every project.