What Is Hardened Clay Called?

What is Hardened Clay?

Hardened clay, also known as terracotta, is clay that has been fired at high temperatures in a kiln to permanently harden it. The firing process changes the physical and chemical properties of the clay and locks its structure in place. Hardened clay can no longer be returned to its soft, moldable form.

Clay becomes terracotta at firing temperatures between 1000-1200°C. At these high temperatures, water molecules trapped in the clay structure are driven off, causing the clay particles to fuse together in a process called sintering. This hardens the clay permanently.

The properties of hardened clay depend on the mineral composition of the original clay body and the firing temperature. In general, terracotta has a reddish-orange color from iron oxide impurities. It’s also porous from gases escaping during firing, but becomes less porous and denser the higher the firing temperature.

Hardened clay is weather resistant and semi-permeable. It can withstand rain and sun without degrading. The porous nature also allows some moisture transfer without absorbing water directly. These properties make hardened clay useful for architectural purposes, pottery, sculpture, bricks, tiles, and more.

Types of Hardened Clay

There are four main types of hardened clay, each with different properties and uses:

Terracotta

Terracotta is a type of earthenware clay that has been fired at low temperatures between 1000-1150°F. It retains a porous, sandy texture and reddish-orange color. Terracotta is commonly used for pottery, sculptures, and architectural decorations like roof tiles or bricks. It’s an affordable and readily available type of hardened clay.

Earthenware

Earthenware refers to types of hardened clay fired at lower temperatures, typically between 1000-1200°F. Earthenware retains its natural clay color after firing unless glazes or engobes are added. It is slightly denser and less porous than terracotta. Common uses include pottery, tableware, and decorative figures. Earthenware is lightweight and relatively fragile.

Stoneware

Stoneware is fired at higher temperatures ranging from 1200-1300°F. The higher heat makes stoneware non-porous and denser than earthenware or terracotta. Glazes can be applied to create a watertight seal. Stoneware maintains its shape without warping and is more durable for functional pottery or cookware. The firing process gives stoneware a grey, blue, brown, or white color.

Porcelain

Porcelain is highly refined, dense clay fired at very high temperatures of 1300-1400°F. It becomes perfectly non-porous and translucent white in color. Porcelain is highly prized for its strength, hardness, whiteness,translucency and resistance to staining. It is used for fine china dinnerware, vases, figurines, sanitaryware, and electrical insulators.

Creating Hardened Clay

Hardened clay, also known as terracotta, is made from regular clay that undergoes a process of molding, drying, and firing at high temperatures. The production process transforms soft, malleable clay into a hard, durable material.

To create hardened clay objects, the clay preparation is an important first step. Most clay contains impurities that must be removed, such as small stones, vegetation, and organic matter. The clay is processed to achieve an even consistency and texture, usually through steps like soaking, kneading, sieving, and wedging.

Once the clay is prepared, it can be shaped and molded using any technique, from hand-building to throwing on a pottery wheel. Care must be taken during molding to remove air pockets that could expand and crack during firing. The molded clay is left to air-dry slowly to minimize cracking and warping. Drying times vary based on factors like climate conditions, clay thickness, and desired results.

The final step is firing the dried clay objects in a high-temperature kiln, generally between 1000°C and 1300°C. Firing hardens the clay permanently by changing its molecular structure. The clay vitrifies and becomes ceramic during the firing process. Kilns allow control over atmosphere, temperature, and length of firing to achieve the desired results.

With the proper clay preparation, molding technique, controlled drying, and high-temperature firing, soft clay transforms into hardened, durable terracotta objects like sculptures, vessels, bricks, and tiles.

Properties of Hardened Clay

Hardened clay has some unique properties that make it useful for various applications. Some of the key properties of hardened clay include:

Strength

Hardened clay is quite strong compared to unfired clay. The firing process causes chemical changes that lock the clay particles together, increasing hardness and durability. Hardened clay has compressive strength similar to concrete or stone. This allows it to withstand heavy loads and forces without cracking or crumbling.

Porosity

Unlike unfired clay which is porous, hardened clay has very low porosity. The intense heat of firing vitrifies the clay, closing off pores and creating a dense, non-porous material. This makes hardened clay impermeable to water and resistant to weathering. The lack of pores also improves strength.

Thermal Properties

Hardened clay has excellent thermal properties thanks to its dense, non-porous structure. It has low thermal conductivity, meaning it does not easily transfer heat. This helps insulate buildings against temperature changes. Hardened clay also has high specific heat capacity, so it absorbs and retains heat effectively.

Electrical Resistance

With no free electrons, hardened clay is an electrical insulator. This means electricity cannot flow through it easily. Its high electrical resistance is useful for applications like insulators and electrical wiring. Hardened clay’s insulating properties also provide fire resistance.

Uses of Hardened Clay

Hardened clay, also known as terracotta, has been used for thousands of years to create useful and decorative objects. Some of the most common uses of hardened clay include:

Pottery

One of the oldest uses of hardened clay is to produce pottery items like vases, jars, bowls, plates, and other containers. Pottery can be left plain as utilitarian ware or decorated elaborately as art. Terracotta pottery often has a distinctive reddish-orange color from iron oxide baked into the clay.

Sculpture

Sculptures and figurines made from hardened clay allow artisans to shape intricate designs by hand or with molds. Terracotta sculptures are more durable than soft clay and also tend to keep their form better than other materials like wood or wax when exposed to the elements.

Bricks and Tiles

Bricks and roof tiles made from baked clay have been used in construction for thousands of years. Hardened clay bricks last a very long time compared to wood, straw or mud bricks. The durability and fireproof nature of terracotta bricks and tiles make them ideal building materials.

Tableware

Glazed and unglazed terracotta is commonly used to produce plates, bowls, mugs, pitchers and other types of tableware. The porosity of the clay allows air to pass through and provide insulation that keeps drinks cooler. Terracotta tableware is also attractive and earthy in style.

Hardened Clay vs Clay

Hardened clay and regular clay have some key differences in their properties, uses, and composition. While both originate as soft, pliable clay, through a process of drying and firing, hardened clay develops distinct characteristics that set it apart from unfired clay.

The most noticeable difference is in their physical structure. As clay loses moisture and undergoes vitrification at high temperatures, the clay particles fuse, causing it to become dense, non-porous, and rock-hard. Regular clay remains permeable and can be remolded when wet. Hardened clay does not return to a plastic state when wetted. It has a compact texture that makes it more durable and rigid.

The changes created through firing also affect the clay’s chemical makeup. The extreme heat alters the molecular structure of the clay minerals. As a result, hardened clay is less prone to shrinking and cracking compared to regular clay. It obtains increased strength and resistance to weathering and chemical corrosion. These enhanced physical properties give fired clay added versatility in its applications.

While unfired clay is suitable for products like greenware pottery and modeling clay that can air-dry, hardened clay is indispensible for ceramic materials like bricks, tiles, and pottery requiring sturdiness and thermal properties. The impermeable quality of fired clay provides functions regular clay cannot, from cladding furnaces to making liquid-tight containers.

Understanding the unique properties and composition hardened clay gains through firing helps demonstrate the marked differences between these two forms of clay. Hardened clay emerges as a distinctly robust material that lends itself to more specialized roles and applications not possible with just regular clay alone.

Advantages of Hardened Clay

Hardened clay, also known as terracotta, offers many advantages over regular clay and other materials. Some of the main benefits of using hardened clay include:

Durability – Once clay is fired and hardened through high heat, it becomes highly durable and resistant to damage. Hardened clay maintains its structural integrity for centuries. Archaeological artifacts made of terracotta have survived thousands of years.

Heat Resistance – The firing process chemically alters the clay, making it able to withstand high temperatures. Hardened clay items like flower pots and oven tiles can be subjected to temperatures over 2,000°F without damage.

Cost-Effectiveness – Clay is an abundant natural material found all over the world. With minimal processing, it can be shaped while wet and hardened through firing. This makes clay products economical compared to other materials.

Moldability – In its wet form, clay is highly moldable and can be shaped into endless forms both by hand and with molds. This allows artisans to create intricate decorative objects and functional wares using clay.

Disadvantages of Hardened Clay

While hardened clay has many useful properties, it also comes with some drawbacks that should be considered when working with it. The main disadvantages of hardened clay are its brittleness, heaviness, and porousness.

Hardened clay’s brittleness makes it prone to cracking and breaking, especially when exposed to sudden temperature changes or blunt force impacts. Pieces made of hardened clay need to be handled gently to avoid shattering them. Hardened clay’s brittleness also makes it difficult to carve intricate details without risk of the clay cracking.

The dense, compact nature of hardened clay also makes it quite heavy compared to other sculpting materials. Large pieces or sculptures made from hardened clay can be cumbersome and difficult to move around. The weight also puts more strain on armatures or structural supports when working on large-scale clay projects.

Hardened clay is naturally porous, which allows it to absorb liquids and moisture from the air. This porosity makes pieces vulnerable to weathering and deterioration over time if not properly sealed and protected. It also means that water-based clays and glazes may not hold well on the surface.

Being aware of these drawbacks allows artists and crafters to plan their hardened clay projects accordingly, and take steps to mitigate any potential issues that may arise from the material’s inherent disadvantages.

Notable Hardened Clay Objects

Throughout history, civilizations around the world have created remarkable works of art and architecture using hardened clay. Here are some of the most notable examples:

Terracotta Army

The Terracotta Army is one of China’s most famous archaeological discoveries. This army of over 8,000 life-size terracotta soldier figures was buried near the tomb of Qin Shi Huang, the first emperor of China, around 210 BC. Each soldier figure was individually crafted with unique facial features and details. The Terracotta Army represents the vast military force that helped Qin Shi Huang unify China and establish the Qin dynasty.

Ancient Greek Pottery

From delicate black-figure vases to iconic red-figure pots, hardened clay enabled the ancient Greeks to create lasting masterpieces. Greek potters shaped, painted, and fired clay into vessels of all shapes and sizes. Painted Greek pots depicted myths, everyday scenes, athletes, gods, and more. The styles and imagery of Greek pottery evolved over centuries as fashions changed. Today, these ceramics provide insight into ancient Greek culture and artistry.

Mesoamerican Sculpture

Clay sculpture flourished in Mesoamerica for thousands of years. The Olmecs produced the earliest known figurines and bas-reliefs, followed by the Maya and cultures such as the Zapotecs, Mixtecs, and Aztecs. These civilizations shaped clay from the region’s abundant natural sources into stunning and detailed works depicting gods, rulers, animals, and human activities. The clay sculptures provide archaeologists understanding into the cosmology, rituals, and daily life of Mesoamerica’s pre-Columbian cultures.

Future of Hardened Clay

Hardened clay has a bright future ahead with new techniques being developed to improve its sustainability and discover innovative uses. Some key areas of development include:

New Techniques

Researchers are developing new environmentally-friendly techniques to harden clay without firing, such as using citric acid. This reduces the carbon footprint of hardened clay production. New 3D printing technologies are also enabling more intricate hardened clay objects to be created with less waste.

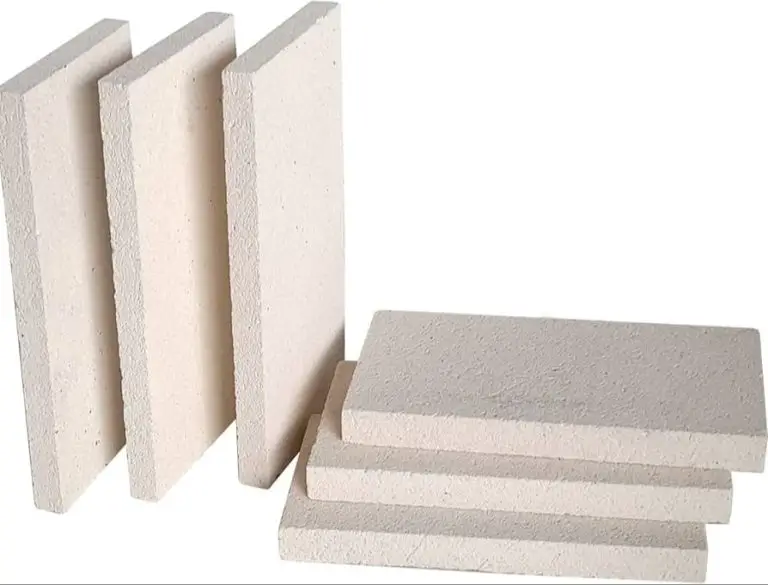

Innovative Uses

From art installations to sustainable building materials, designers are finding creative new uses for hardened clay. For example, mixing clay with straw can create durable bricks. Hardened clay is also being used in new forms like decorative wall panels.

Sustainability

Creating hardened clay objects locally using sustainable practices reduces environmental impact. There is also research into recycling hardened clay back into usable clay. The future looks bright for eco-friendly production and reuse of this venerable material.