What Does A Power Control Relay Do?

A power control relay is an electromechanical device that uses an electromagnet to open or close electrical contacts and control a circuit. Power control relays allow a low power circuit to switch a higher power circuit on or off while providing isolation between the control and switched circuits.

Power control relays are commonly used in industrial control systems and automation applications. Some typical uses include controlling motors, pumps, conveyors, compressors, and other types of industrial machinery. They provide automated on/off control based on input signals from sensors, switches, or electronic controllers. Power control relays allow high power equipment to be safely controlled by lower power control circuits.

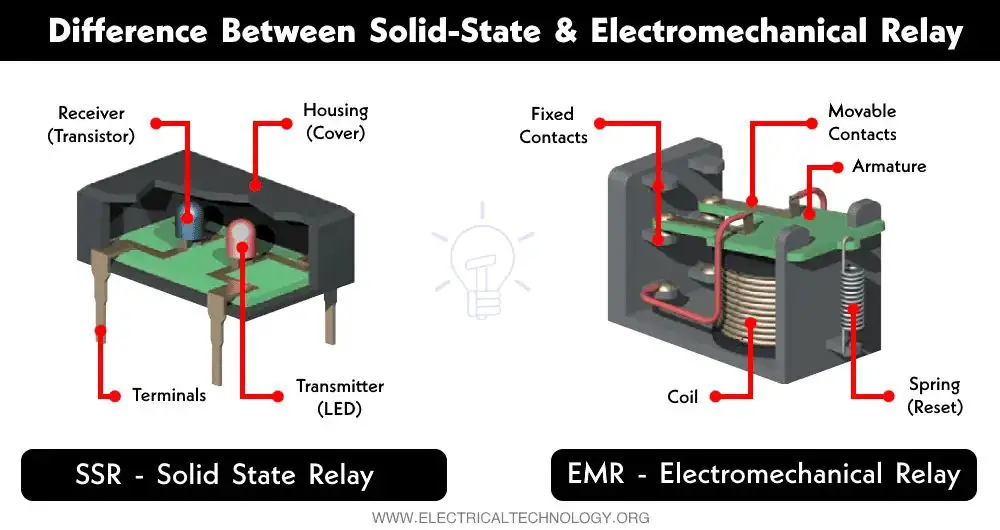

Compared to a regular mechanical relay, a power control relay can handle higher voltages and currents. They provide reliable electrical isolation and contact protection. Common power control relay designs include electromechanical, solid state, and hybrid relays. The specific relay type is chosen based on the electrical load requirements and switching speed needed.

How Power Control Relays Work

A power control relay consists of a few basic components that allow it to open or close an electrical circuit. The main components are:

- Coil – This is an electromagnet made of coiled wire that generates a magnetic field when current flows through it.

- Armature – A movable iron core that is attracted by the magnetic field created by the coil.

- Contacts – Stationary electrical contacts that the armature connects or disconnects.

In a basic control relay circuit, the coil is connected to a power source and control switch. When the control switch is closed, current flows through the coil, generating a magnetic field. This magnetic field attracts the armature, which pivots and connects the stationary contacts. This closes the output circuit that is connected to the contacts. When the control switch is opened, current stops flowing through the coil, so the magnetic field collapses. The armature spring then pulls the armature back to disconnect the contacts and open the output circuit.

Therefore, the switching mechanism works through electromagnetic attraction induced by current flow through the coil. Varying the current in the coil circuit controls the on/off state of the output circuit connected to the contacts.

Types of Power Control Relays

There are three main types of power control relays:

Electromechanical Relays

Electromechanical relays are the most common and traditional type of relay. They operate using an electromagnet to mechanically control electrical contacts. When voltage is applied to the electromagnet coil, it creates a magnetic field that activates the armature and changes the state of the contacts. Electromechanical relays are simple, rugged, and inexpensive but have slower switching speeds compared to solid state relays.

Solid State Relays

Solid state relays (SSRs) use semiconductor switching devices like thyristors, transistors, and SCRs instead of mechanical contacts. They switch on and off much faster than electromechanical relays and have no moving parts to wear out. However, SSRs can be sensitive to voltage spikes and surges. They also may not work well for switching some inductive loads due to back EMF. SSRs cost more than mechanical relays.

Hybrid Relays

Hybrid relays combine an electromechanical relay and a solid state relay together in one package. They use the electromechanical relay contacts for switching current while the solid state components control the coil voltage. This provides arc suppression and a long service life. Hybrid relays have faster switching speeds than electromechanical alone but are more expensive.

Advantages of Power Control Relays

Power control relays offer several key advantages that make them a popular choice for many automation and control applications:

Accuracy: Relays are highly accurate electrical switches, able to switch circuits ON and OFF with precision timing. This makes them well-suited for applications that require accurate, repeatable control functions.

Long Lifespan: Due to their rugged, mechanical design, relays can have extremely long lifespans, often rated for millions of operations. Quality relays that are properly maintained can provide decades of reliable service.

Withstand Voltage Spikes: Relays are designed to withstand voltage spikes, surges and electrical noise that could damage sensitive electronic controls. Their electromechanical contacts provide good electrical isolation and noise resistance.

(Source)

Disadvantages of Power Control Relays

While power control relays offer many benefits, they also have some drawbacks to consider:

Higher initial cost – Power control relays typically cost more upfront than comparably rated electromechanical relays. The use of solid state components and printed circuit boards increases manufacturing costs.[1]

Not ideal for low power applications – The internal circuitry of power control relays requires a minimum load power level to operate properly. Electromechanical relays are more suitable for switching very low level signals.

Applications of Power Control Relays

Power control relays have a wide variety of applications across many industries and systems. Some of the most common applications include:

Motor Controls

Power control relays are extensively used in motor control circuits. They allow motors to be remotely started and stopped by opening or closing their contacts. Control relays are used in both AC and DC motor control systems.

HVAC Systems

HVAC systems rely on control relays to activate compressors, fans, pumps, and heating elements. The relays provide automated on/off control and overload protection for the HVAC components. Control relays allow HVAC systems to maintain proper ventilation, temperature, and humidity.

Automated Lighting

Control relays allow lighting systems to be automated based on schedules, occupancy, daylight levels and other inputs. The relays switch lights on or off by making/breaking contact with the lighting circuit. Automated lighting increases efficiency and provides intelligent control in buildings and facilities.

Specifications to Look for When Selecting

When selecting a power control relay, three key specifications to consider are voltage and current ratings, switching speed, and contact material.

Voltage and current ratings indicate the electrical load the relay can handle. It’s important to choose a relay with a voltage rating greater than the circuit voltage to ensure proper operation. The current rating should also exceed the maximum current that will flow through the contacts (Machine Design, 2002). Exceeding the ratings can damage the relay.

Switching speed refers to how fast the relay can open and close its contacts. Fast switching relays are designed for rapid on/off cycling. Choose the speed based on your switching frequency requirements (Woodrich, LinkedIn).

Contact material affects durability and conductivity. Common materials are silver, gold, and palladium. Silver offers good conductivity at a lower cost but is more prone to oxidation. Gold has the highest conductivity and is highly resistant to corrosion. Palladium is in the middle in terms of cost, conductivity, and resistance to oxidation.

Installation and Maintenance

Proper installation and maintenance are crucial for power control relays to operate reliably and accurately. Here are some key considerations:

Mounting

Power control relays are typically mounted on a DIN rail inside an electrical panel or enclosure. Ensure the relay is securely mounted and doesn’t have excessive vibration which could loosen connections. Leave sufficient space around the relay for access and cooling.

Wiring

Follow the wiring diagram precisely, using the specified wire gauges for each terminal. Double check all connections are tight and secure. Use ferrules or wire end sleeves on stranded wires. Take care not to overload the relay contacts with more current than rated.

Protection from Dirt/Debris

Ensure the electrical enclosure has proper seals and gaskets to prevent dirt, moisture and contaminants from entering. Power control relays contain sensitive electronic components that can fail if exposed to debris or humidity over time. Regular inspection and cleaning is advised.

Safety Considerations

When working with power control relays, it is crucial to follow safety guidelines to avoid hazards:

Select power control relays with proper voltage and current ratings for the application. Using an under-rated relay can lead to overheating and potential fire hazards. Refer to manufacturer specifications and choose relays that meet or exceed the expected electrical loads (NHTSA, 2017).

Install power control relays in suitable enclosures that protect the components from environmental contaminants like dirt and moisture. The enclosures should meet specified ingress protection (IP) ratings based on the operating environment. Poor enclosures can allow contaminants to enter and cause shorts or corrosion.

Use warning labels and signs to indicate the presence of live power. Relays may switch on powered equipment without warning, creating electrical hazards. Warning labels help prevent accidental contact with live parts.

Adhering to proper relay ratings, enclosures, and warning signs helps minimize safety risks when utilizing power control relays.

Future Trends

Power relays are expected to evolve in several key ways in the coming years, incorporating new technologies and capabilities:

Internet of Things Integration: More power relays will have built-in network connectivity, allowing them to communicate real-time data and be monitored or controlled remotely. This Internet of Things (IoT) integration will enable more intelligent power management and automation. According to Tongling Relays, network-enabled relays will become the norm in the future.

Miniaturization: Power relays will continue getting smaller and more compact. Micro-miniature relays take up less space and weight, allowing for greater design flexibility. Improved power electronics and manufacturing techniques will further the miniaturization trend. As relays shrink in size, their functionality and reliability will continue improving.

Enhanced Diagnostics: More advanced power relays will incorporate built-in sensors, self-monitoring capabilities, and diagnostics features. This will enable earlier failure detection, predictive maintenance alerts, and overall smarter management of the relay. Improved diagnostics will minimize costly downtime and faults. According to a LinkedIn report, the protective relays market is moving towards more condition monitoring and self-diagnostic capabilities.